12

Operating Precautions

The following operating and safety precautions must be observed in order to avoid harm to the operator or damage to the drill press.

1.The head assembly must be locked to the column so the thrust produced by drilling will not force the head assembly up the column.

2.The work table must be locked to the column so it will not be forced down the column.

3.Before drilling, release the quill lock nut to permit free travel of the quill.

4.Be sure the belt is tightened to the proper tension.

5.DO NOT start to drill the workpiece until making certain the workpiece is held down securely.

6.MAKE SURE THE DRIVE MOTOR IS RUN- NING BEFORE turning the speed control handwheel in either direction.

7.Point of operation protection is required for maximum safety. This remains the responsibil- ity of the user/purchaser since conditions differ between jobs.

8.Make sure the drill is secured in the spindle or check before attempting to use the drill press.

9.Make sure the spindle taper is clean and free of burrs, scoring, and galling to assure maximum gripping.

10.Lock the quill in position when using and side- loaded tool.

Drilling Recommendations

Speeds for Drilling

The speed of a drill is usually measured in terms of the rate at which the outer periphery of the tool moves in relation to the work being drilled. The common term for this is Surface Feet per Minute (SFM). The relationship of SFM is expressed in the following formulas:

SFM = 0.26 X rpm X Drill Diameter (in inches) RPM = 3.8 x ________SFM__________

Drill diameter (in inches)

In general, the higher the speed the shorter the drill life. Operating at the low end of the speed range for a particular material will result in longer life. The most efficient speed for operating a drill depends on many variables:

1.Composition and hardness of material.

2.Depth of the hole.

3.Efficiency of the cutting fluid.

4.Type and condition of the drilling machine.

5.Desired quality of the hole.

6.Difficulty of

Feeds for Drilling

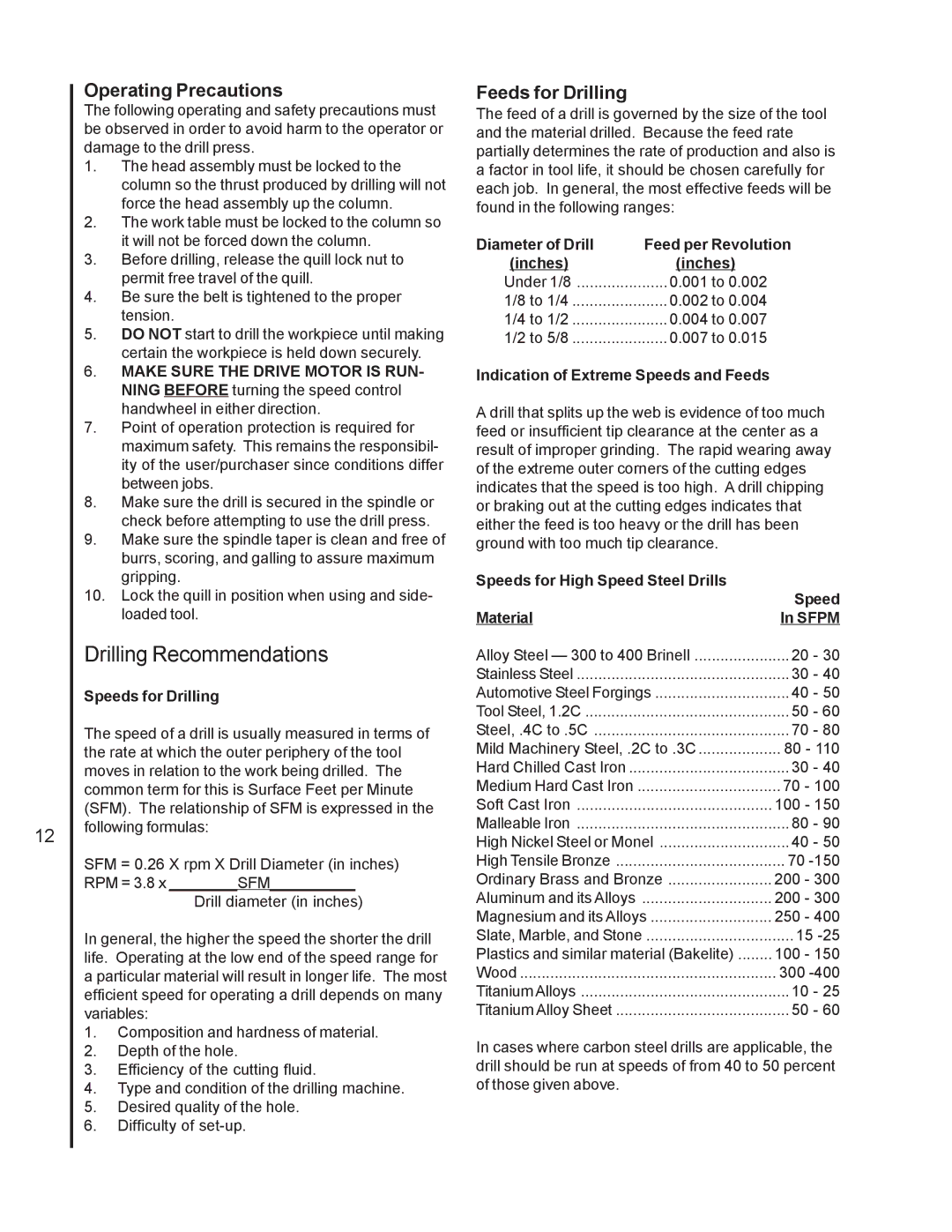

The feed of a drill is governed by the size of the tool and the material drilled. Because the feed rate partially determines the rate of production and also is a factor in tool life, it should be chosen carefully for each job. In general, the most effective feeds will be found in the following ranges:

Diameter of Drill | Feed per Revolution |

(inches) | (inches) |

Under 1/8 | 0.001 to 0.002 |

1/8 to 1/4 | 0.002 to 0.004 |

1/4 to 1/2 | 0.004 to 0.007 |

1/2 to 5/8 | 0.007 to 0.015 |

Indication of Extreme Speeds and Feeds

A drill that splits up the web is evidence of too much feed or insufficient tip clearance at the center as a result of improper grinding. The rapid wearing away of the extreme outer corners of the cutting edges indicates that the speed is too high. A drill chipping or braking out at the cutting edges indicates that either the feed is too heavy or the drill has been ground with too much tip clearance.

Speeds for High Speed Steel Drills | Speed | |

| ||

Material | In SFPM | |

Alloy Steel — 300 to 400 Brinell | 20 - 30 | |

Stainless Steel | 30 - 40 | |

Automotive Steel Forgings | 40 - 50 | |

Tool Steel, 1.2C | 50 - 60 | |

Steel, .4C to .5C | 70 - 80 | |

Mild Machinery Steel, .2C to .3C | 80 - 110 | |

Hard Chilled Cast Iron | 30 - 40 | |

Medium Hard Cast Iron | 70 | - 100 |

Soft Cast Iron | 100 | - 150 |

Malleable Iron | 80 - 90 | |

High Nickel Steel or Monel | 40 - 50 | |

High Tensile Bronze | 70 | |

Ordinary Brass and Bronze | 200 | - 300 |

Aluminum and its Alloys | 200 | - 300 |

Magnesium and its Alloys | 250 | - 400 |

Slate, Marble, and Stone | 15 | |

Plastics and similar material (Bakelite) | 100 | - 150 |

Wood | 300 | |

Titanium Alloys | 10 - 25 | |

Titanium Alloy Sheet | 50 - 60 | |

In cases where carbon steel drills are applicable, the drill should be run at speeds of from 40 to 50 percent of those given above.