MAINTENANCE

DAILY MAINTENANCE

1.Vacuum unused cleaning solution from solution tank into recovery bucket.

2.Flush two gallons of clean water through pumping system of extractor, PILEJOGGER and hand tools. Twice a month, flush a vinegar solution (one quart white vinegar to two gallons water) or browning prevent solution (mixed as directed) through extractor and PILEJOGGER. This will minimize buildup of alkaline residue in the system.

3.Remove carpet lint from brush fibers and underside of brush housing. Flush out with water.

4.Check for carpet lint buildup in vac shoe. Clean out and flush with water.

5.If spray jets become clogged, remove from manifold, wash and

6.Apply silicone lubricant to

TROUBLESHOOTING

PROBLEM. | CAUSE | SOLUTION | |

|

|

| |

No power to brush | Dead electrical circuit | Check building circuit breaker or fuse box | |

| Faulty switch | Replace | |

| Faulty electrical cable | Replace | |

|

|

| |

Brush motor speed | Faulty motor | Replace | |

varies or doesn’t run | |||

|

| ||

| Faulty switch | Replace | |

Loss of vacuum | Loose cuff on vac hose | Tighten cuffs (turn counterclockwise) | |

| Vac chamber plugged | Wash out with hose. Pick lint out with wire. | |

| Broken vac hose | Replace | |

Solution hose quick | Corrosion on fittings | Clean fitting by soaking in vinegar solution, lubricate | |

disconnects hard to | |||

lightly with silicon lube | |||

insert |

| ||

|

| ||

Solution won’t shut off | Faulty solution valve | Repair or replace | |

Clogged spray jets | Corrosion | Clean with steel wool and vinegar solution; wipe dry | |

after each use. | |||

|

| ||

Carpet not clean | Severe soil conditions | Make more than one pass at right angle to first pass. | |

Prespray. | |||

|

| ||

Carpet too wet | Loss of vacuum | Check vac system for leaks |

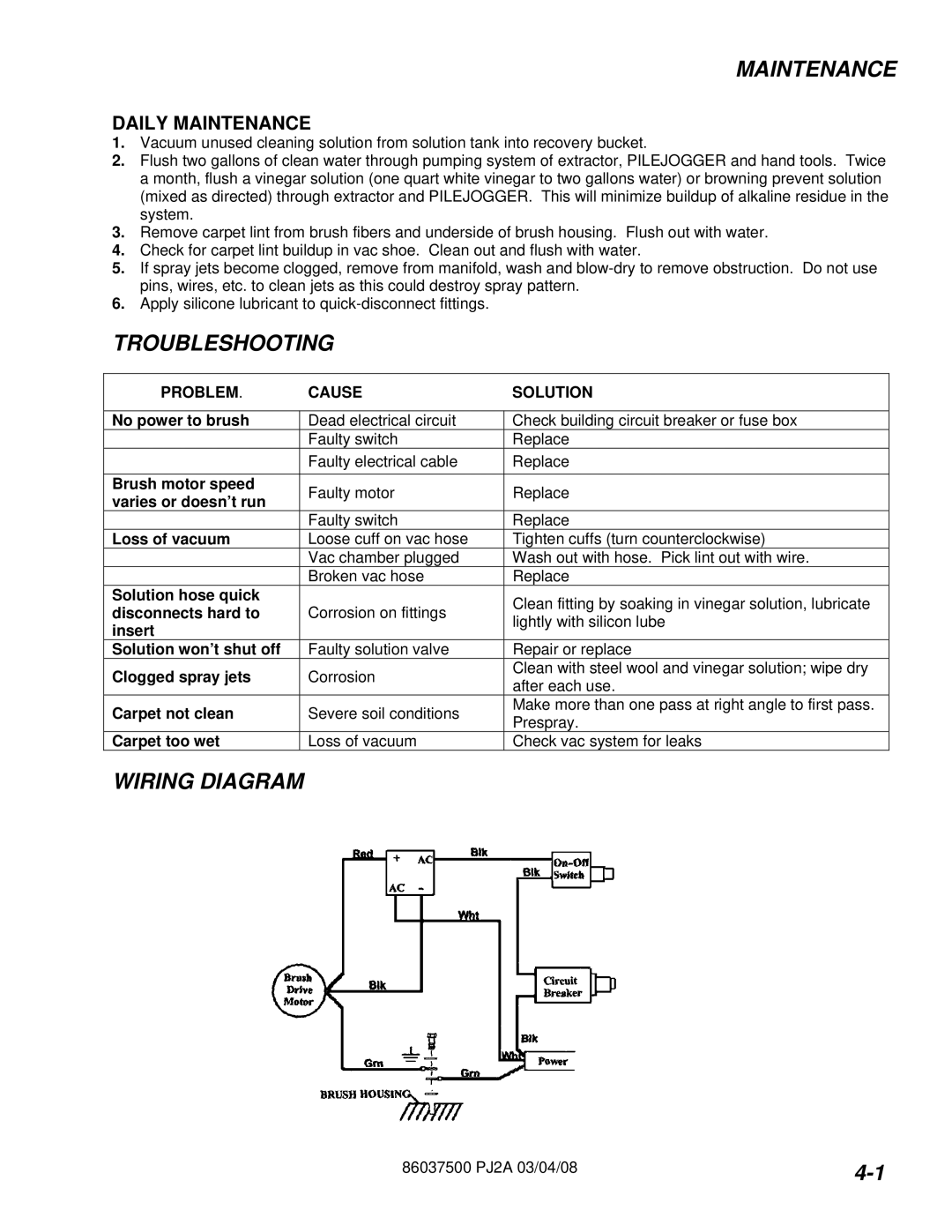

WIRING DIAGRAM

86037500 PJ2A 03/04/08 | |

|