LUBRICATION

Keep all persons away from operator control area while performing adjustments, service, or maintenance.

Do not let excess grease collect on or around parts, particularly when operating in sandy areas.

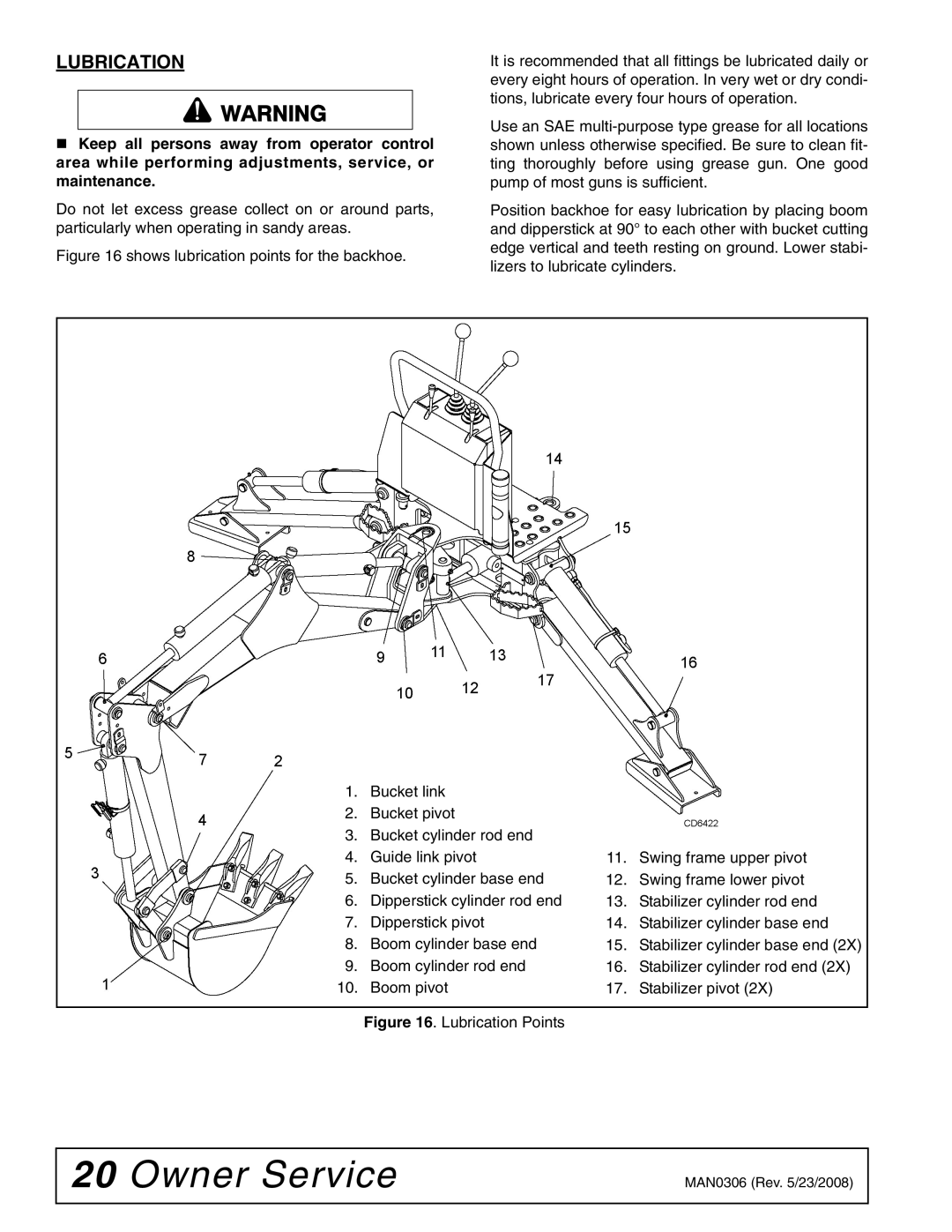

Figure 16 shows lubrication points for the backhoe.

It is recommended that all fittings be lubricated daily or every eight hours of operation. In very wet or dry condi- tions, lubricate every four hours of operation.

Use an SAE multi-purpose type grease for all locations shown unless otherwise specified. Be sure to clean fit- ting thoroughly before using grease gun. One good pump of most guns is sufficient.

Position backhoe for easy lubrication by placing boom and dipperstick at 90° to each other with bucket cutting edge vertical and teeth resting on ground. Lower stabi- lizers to lubricate cylinders.

1.Bucket link

2.Bucket pivot

3.Bucket cylinder rod end

4.Guide link pivot

5.Bucket cylinder base end

6.Dipperstick cylinder rod end

7.Dipperstick pivot

8.Boom cylinder base end

9.Boom cylinder rod end

10.Boom pivot

11.Swing frame upper pivot

12.Swing frame lower pivot

13.Stabilizer cylinder rod end

14.Stabilizer cylinder base end

15.Stabilizer cylinder base end (2X)

16.Stabilizer cylinder rod end (2X)

17.Stabilizer pivot (2X)

Figure 16. Lubrication Points

20 Owner Service | MAN0306 (Rev. 5/23/2008) |

|

|