16.Check that the gear backlash is between 0.006" and 0.016". You should not have to adjust the backlash.

17.Press in input oil seal (19), using tube of correct diameter. Be careful not to damage seal lip.

18.Press oil cap (20) on to cover the rear of housing, using a tube of the correct diameter.

19.Place top cover (22) on top of housing and secure with six cap screw (23).

20.Check gearbox housing for leaks by plugging all holes except one. Apply 4 psi compressed air and immerse the gearbox in water to verify that there are no leaks.

21.Remove gearbox from water and dry off with compressed air. Add SAE 80W or 90W EP oil until it runs out of side level hole. Tighten all plugs.

Reinstallation

NOTE: Gearbox is heavy: do not attempt to move with- out mechanical assistance.

1.Set gearbox on cutter and fasten with bolts and nuts. Torque bolts to 300

2.Attach crossbar (Crossbar Installation, page 37).

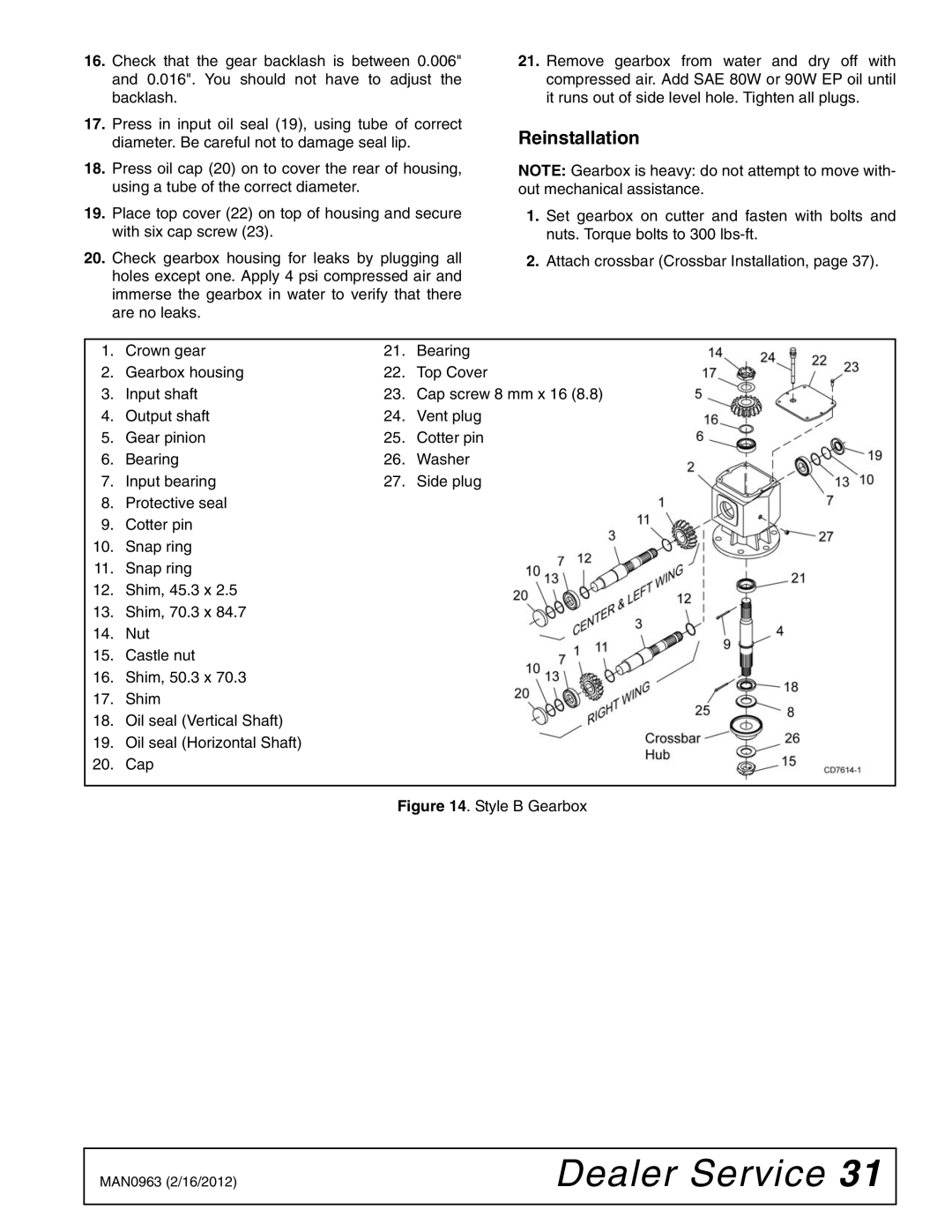

1. | Crown gear | 21. | Bearing |

2. | Gearbox housing | 22. | Top Cover |

3. | Input shaft | 23. | Cap screw 8 mm x 16 (8.8) |

4. | Output shaft | 24. | Vent plug |

5. | Gear pinion | 25. | Cotter pin |

6. | Bearing | 26. | Washer |

7. | Input bearing | 27. | Side plug |

8. | Protective seal |

|

|

9. | Cotter pin |

|

|

10. | Snap ring |

|

|

11. | Snap ring |

|

|

12. | Shim, 45.3 x 2.5 |

|

|

13. | Shim, 70.3 x 84.7 |

|

|

14. | Nut |

|

|

15. | Castle nut |

|

|

16. | Shim, 50.3 x 70.3 |

|

|

17. | Shim |

|

|

18. | Oil seal (Vertical Shaft) |

|

|

19. | Oil seal (Horizontal Shaft) |

|

|

20. | Cap |

|

|

Figure 14. Style B Gearbox

MAN0963 (2/16/2012) | Dealer Service 31 |

|

|