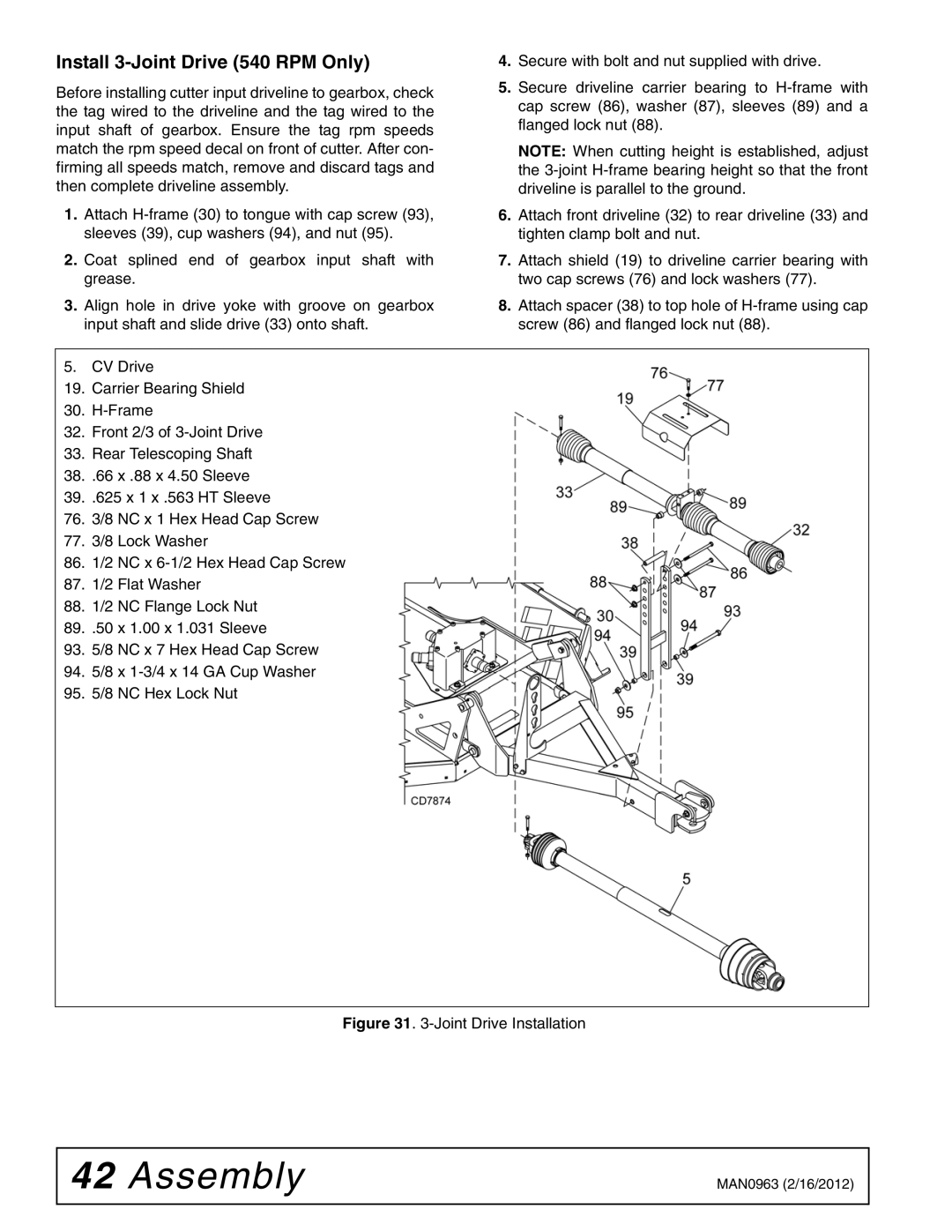

Install 3-Joint Drive (540 RPM Only)

Before installing cutter input driveline to gearbox, check the tag wired to the driveline and the tag wired to the input shaft of gearbox. Ensure the tag rpm speeds match the rpm speed decal on front of cutter. After con- firming all speeds match, remove and discard tags and then complete driveline assembly.

1.Attach

2.Coat splined end of gearbox input shaft with grease.

3.Align hole in drive yoke with groove on gearbox input shaft and slide drive (33) onto shaft.

4.Secure with bolt and nut supplied with drive.

5.Secure driveline carrier bearing to

NOTE: When cutting height is established, adjust the

6.Attach front driveline (32) to rear driveline (33) and tighten clamp bolt and nut.

7.Attach shield (19) to driveline carrier bearing with two cap screws (76) and lock washers (77).

8.Attach spacer (38) to top hole of

5. CV Drive

19.Carrier Bearing Shield

30.

32.Front 2/3 of

33.Rear Telescoping Shaft

38..66 x .88 x 4.50 Sleeve

39..625 x 1 x .563 HT Sleeve

76.3/8 NC x 1 Hex Head Cap Screw

77.3/8 Lock Washer

86.1/2 NC x

87.1/2 Flat Washer

88.1/2 NC Flange Lock Nut

89..50 x 1.00 x 1.031 Sleeve

93.5/8 NC x 7 Hex Head Cap Screw

94.5/8 x

95.5/8 NC Hex Lock Nut

Figure 31. 3-Joint Drive Installation

42 Assembly | MAN0963 (2/16/2012) |

|

|