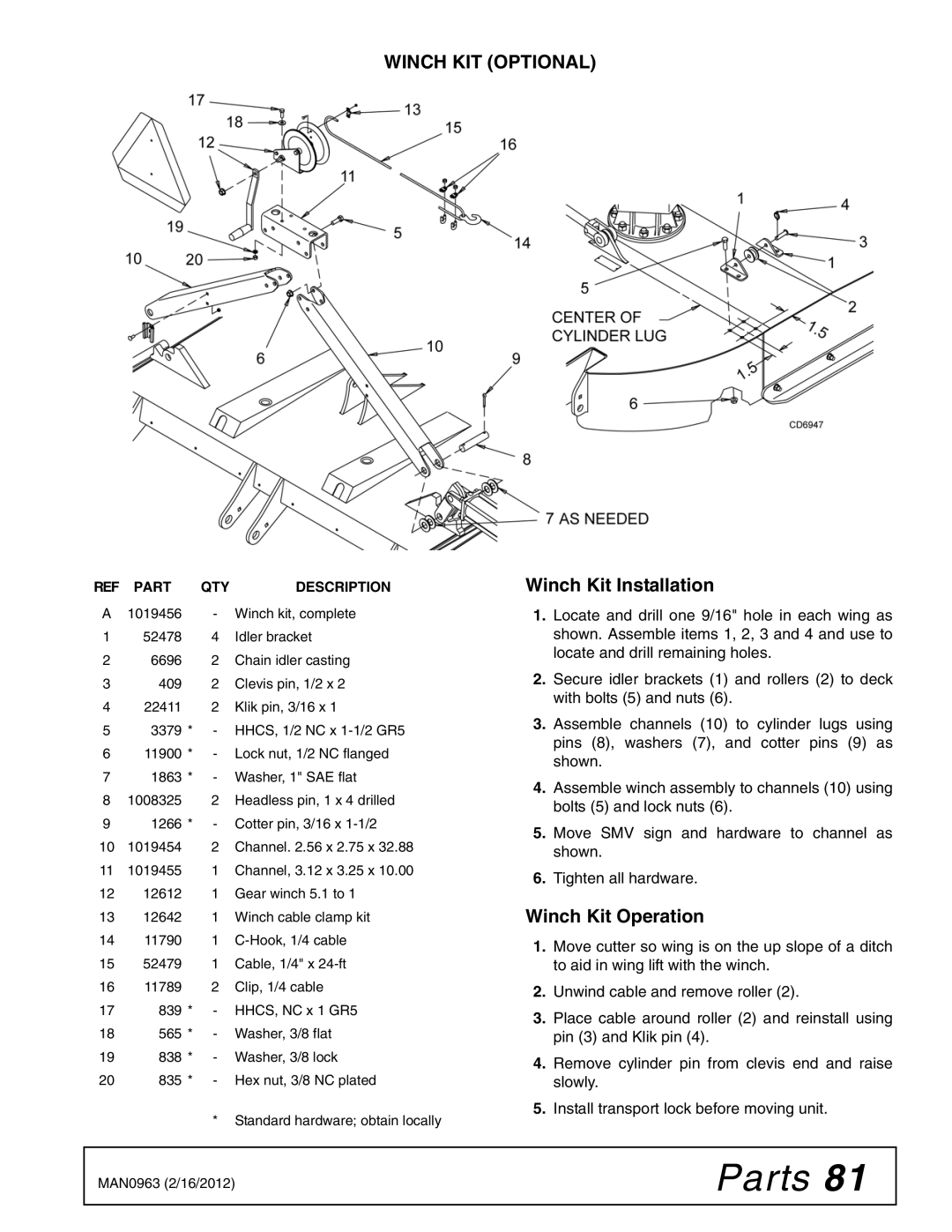

WINCH KIT (OPTIONAL)

REF | PART |

| QTY | DESCRIPTION |

A | 1019456 |

| - | Winch kit, complete |

1 | 52478 |

| 4 | Idler bracket |

2 | 6696 |

| 2 | Chain idler casting |

3 | 409 |

| 2 | Clevis pin, 1/2 x 2 |

4 | 22411 |

| 2 | Klik pin, 3/16 x 1 |

5 | 3379 | * | - | HHCS, 1/2 NC x |

6 | 11900 | * | - | Lock nut, 1/2 NC flanged |

7 | 1863 | * | - | Washer, 1" SAE flat |

8 | 1008325 |

| 2 | Headless pin, 1 x 4 drilled |

9 | 1266 | * | - | Cotter pin, 3/16 x |

10 | 1019454 |

| 2 | Channel. 2.56 x 2.75 x 32.88 |

11 | 1019455 |

| 1 | Channel, 3.12 x 3.25 x 10.00 |

12 | 12612 |

| 1 | Gear winch 5.1 to 1 |

13 | 12642 |

| 1 | Winch cable clamp kit |

14 | 11790 |

| 1 | |

15 | 52479 |

| 1 | Cable, 1/4" x |

16 | 11789 |

| 2 | Clip, 1/4 cable |

17 | 839 | * | - | HHCS, NC x 1 GR5 |

18 | 565 | * | - | Washer, 3/8 flat |

19 | 838 | * | - | Washer, 3/8 lock |

20 | 835 | * | - | Hex nut, 3/8 NC plated |

|

|

| * | Standard hardware; obtain locally |

Winch Kit Installation

1.Locate and drill one 9/16" hole in each wing as shown. Assemble items 1, 2, 3 and 4 and use to locate and drill remaining holes.

2.Secure idler brackets (1) and rollers (2) to deck with bolts (5) and nuts (6).

3.Assemble channels (10) to cylinder lugs using pins (8), washers (7), and cotter pins (9) as shown.

4.Assemble winch assembly to channels (10) using bolts (5) and lock nuts (6).

5.Move SMV sign and hardware to channel as shown.

6.Tighten all hardware.

Winch Kit Operation

1.Move cutter so wing is on the up slope of a ditch to aid in wing lift with the winch.

2.Unwind cable and remove roller (2).

3.Place cable around roller (2) and reinstall using pin (3) and Klik pin (4).

4.Remove cylinder pin from clevis end and raise slowly.

5.Install transport lock before moving unit.

MAN0963 (2/16/2012) | Parts 81 |

| |

|

|