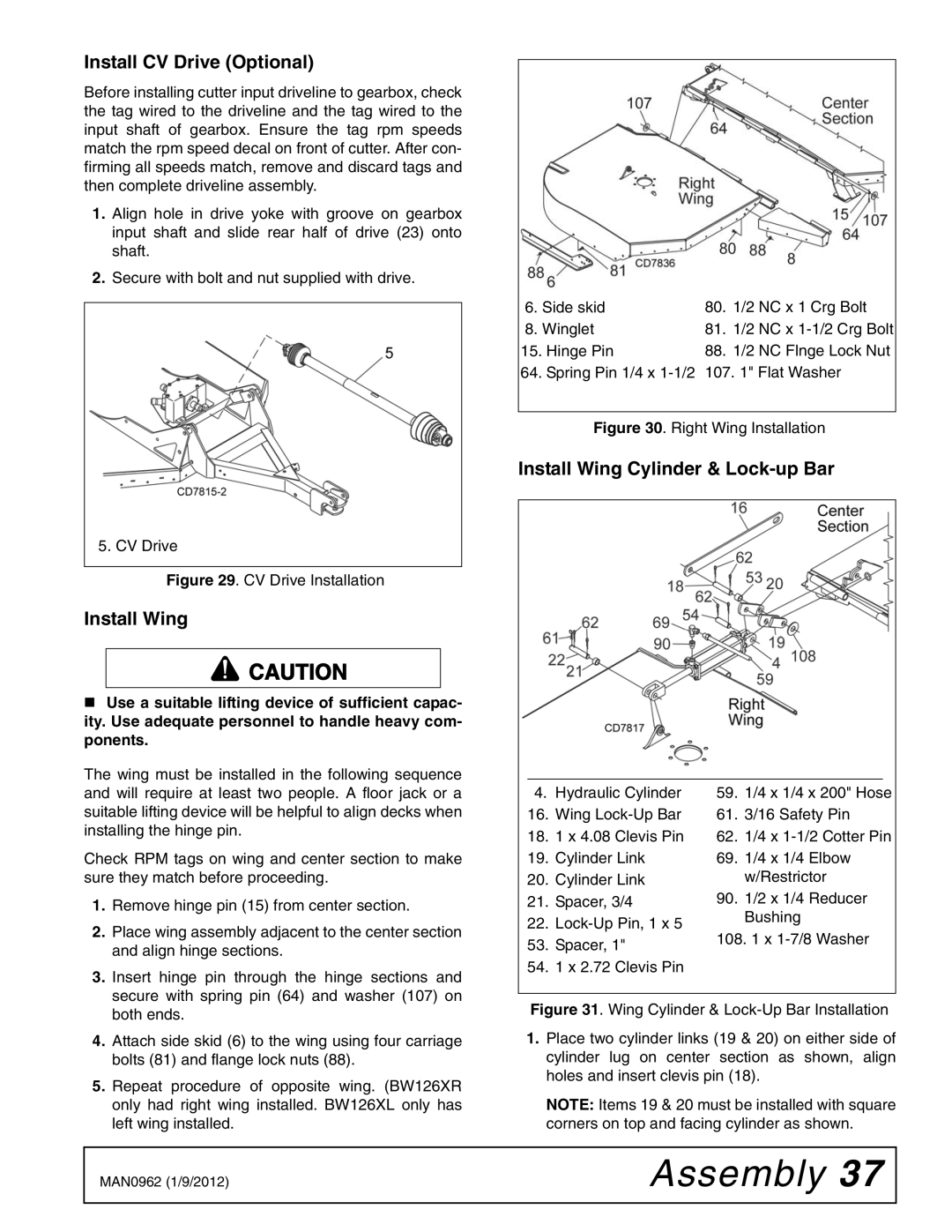

Install CV Drive (Optional)

Before installing cutter input driveline to gearbox, check the tag wired to the driveline and the tag wired to the input shaft of gearbox. Ensure the tag rpm speeds match the rpm speed decal on front of cutter. After con- firming all speeds match, remove and discard tags and then complete driveline assembly.

1.Align hole in drive yoke with groove on gearbox input shaft and slide rear half of drive (23) onto shaft.

2.Secure with bolt and nut supplied with drive.

5. CV Drive

Figure 29. CV Drive Installation

Install Wing

![]() CAUTION

CAUTION

Use a suitable lifting device of sufficient capac- ity. Use adequate personnel to handle heavy com- ponents.

6. | Side skid | 80. | 1/2 NC x 1 Crg Bolt |

8. | Winglet | 81. | 1/2 NC x |

15. Hinge Pin | 88. | 1/2 NC Flnge Lock Nut | |

64. Spring Pin 1/4 x

Figure 30. Right Wing Installation

Install Wing Cylinder & Lock-up Bar

The wing must be installed in the following sequence and will require at least two people. A floor jack or a suitable lifting device will be helpful to align decks when installing the hinge pin.

Check RPM tags on wing and center section to make sure they match before proceeding.

1. | Remove hinge pin (15) from center section. |

2. | Place wing assembly adjacent to the center section |

| and align hinge sections. |

3. | Insert hinge pin through the hinge sections and |

| secure with spring pin (64) and washer (107) on |

4.Hydraulic Cylinder

16. Wing

18. 1 x 4.08 Clevis Pin

19. Cylinder Link

20. Cylinder Link

21. Spacer, 3/4

22.

53. Spacer, 1"

54. 1 x 2.72 Clevis Pin

59.1/4 x 1/4 x 200" Hose

61.3/16 Safety Pin

62.1/4 x

69.1/4 x 1/4 Elbow w/Restrictor

90.1/2 x 1/4 Reducer Bushing

108. 1 x

| both ends. |

4. | Attach side skid (6) to the wing using four carriage |

| bolts (81) and flange lock nuts (88). |

5. | Repeat procedure of opposite wing. (BW126XR |

| only had right wing installed. BW126XL only has |

| left wing installed. |

Figure 31. Wing Cylinder & Lock-Up Bar Installation

1.Place two cylinder links (19 & 20) on either side of cylinder lug on center section as shown, align holes and insert clevis pin (18).

NOTE: Items 19 & 20 must be installed with square corners on top and facing cylinder as shown.

MAN0962 (1/9/2012) | Assembly 37 |

|

|