3.Insert shaft assembly with bearing and spacer into spindle housing from the bottom.

4.Install upper bearing (5) over shaft with the seal facing up.

5.Install spacer (4) and sheave (3) over shaft.

6.Align keyways in shaft and sheave and insert key (11).

7.Install washer (2), and bolt (1). Torque bolt to 35

8.Rotate sheave and check for free movement.

9.Lubricate spindle.

GEARBOX REPAIR

Read this entire section before starting any repair. Many steps are dependent on each other.

Fill gearbox with SAE 80W or 90W gear lube until it runs out the side level plug.

Repair to this gearbox is limited to replacing bearings, seals, and gaskets. Replacing gears, shafts, and a housing is not cost effective. It is more economical to purchase a complete gearbox if repair to anything other than replacement of bearings, seals or gaskets is required.

Inspect gearbox for leakage and bad bearings.

Leakage is a very serious problem and must be cor- rected immediately.

Bearing failure is indicated by excessive noise and side to side or end play in gear shafts.

Seal Replacement

Recommended sealant for gearbox repair is Perma- tex® Aviation 3D

Leakage can occur at the vertical or horizontal gaskets and shaft seals.

Leakage at the horizontal gasket or seal can be repaired without removing the gearbox from the mower.

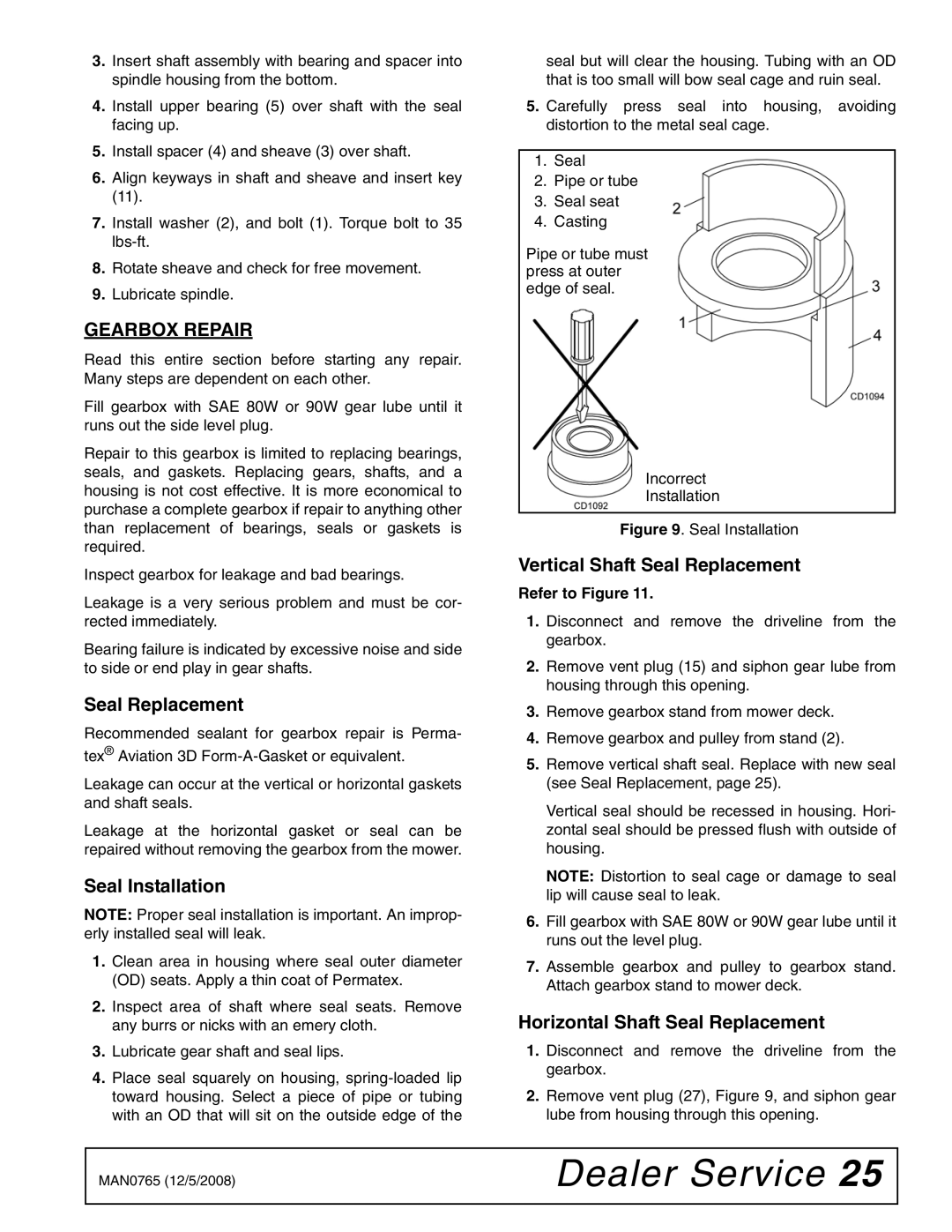

Seal Installation

NOTE: Proper seal installation is important. An improp- erly installed seal will leak.

1.Clean area in housing where seal outer diameter (OD) seats. Apply a thin coat of Permatex.

2.Inspect area of shaft where seal seats. Remove any burrs or nicks with an emery cloth.

3.Lubricate gear shaft and seal lips.

4.Place seal squarely on housing,

seal but will clear the housing. Tubing with an OD that is too small will bow seal cage and ruin seal.

5.Carefully press seal into housing, avoiding distortion to the metal seal cage.

1.Seal

2.Pipe or tube

3.Seal seat

4.Casting

Pipe or tube must press at outer edge of seal.

Incorrect

Installation

Figure 9. Seal Installation

Vertical Shaft Seal Replacement

Refer to Figure 11.

1.Disconnect and remove the driveline from the gearbox.

2.Remove vent plug (15) and siphon gear lube from housing through this opening.

3.Remove gearbox stand from mower deck.

4.Remove gearbox and pulley from stand (2).

5.Remove vertical shaft seal. Replace with new seal (see Seal Replacement, page 25).

Vertical seal should be recessed in housing. Hori- zontal seal should be pressed flush with outside of housing.

NOTE: Distortion to seal cage or damage to seal lip will cause seal to leak.

6.Fill gearbox with SAE 80W or 90W gear lube until it runs out the level plug.

7.Assemble gearbox and pulley to gearbox stand. Attach gearbox stand to mower deck.

Horizontal Shaft Seal Replacement

1.Disconnect and remove the driveline from the gearbox.

2.Remove vent plug (27), Figure 9, and siphon gear lube from housing through this opening.

MAN0765 (12/5/2008) | Dealer Service 25 |

|

|