DEALER SERVICE

The information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you may be time and money ahead to replace complete assemblies.

Before working underneath, read manual instructions, securely block up, and check stability. Secure blocking prevents equipment from drop- ping due to hydraulic leak down, hydraulic system failure, or mechanical component failure.

Keep all persons away from operator control area while performing adjustments, service, or maintenance.

![]() CAUTION

CAUTION

Always wear relatively tight and belted clothing to avoid entanglement in moving parts. Wear sturdy,

BLADE SPINDLE REPAIR

Spindle repair requires special skills and tools. If your shop is not properly equipped or your mechanics are not trained in this type of repair, you may be time and money ahead to use a new spindle assembly.

For reference, the grease fitting is in the top of the spin- dle shaft.

Permatex® 3D Aviation

Remove Spindle

1.Remove belt shields from deck.

2.Remove belt.

3.Remove blade from spindle assembly.

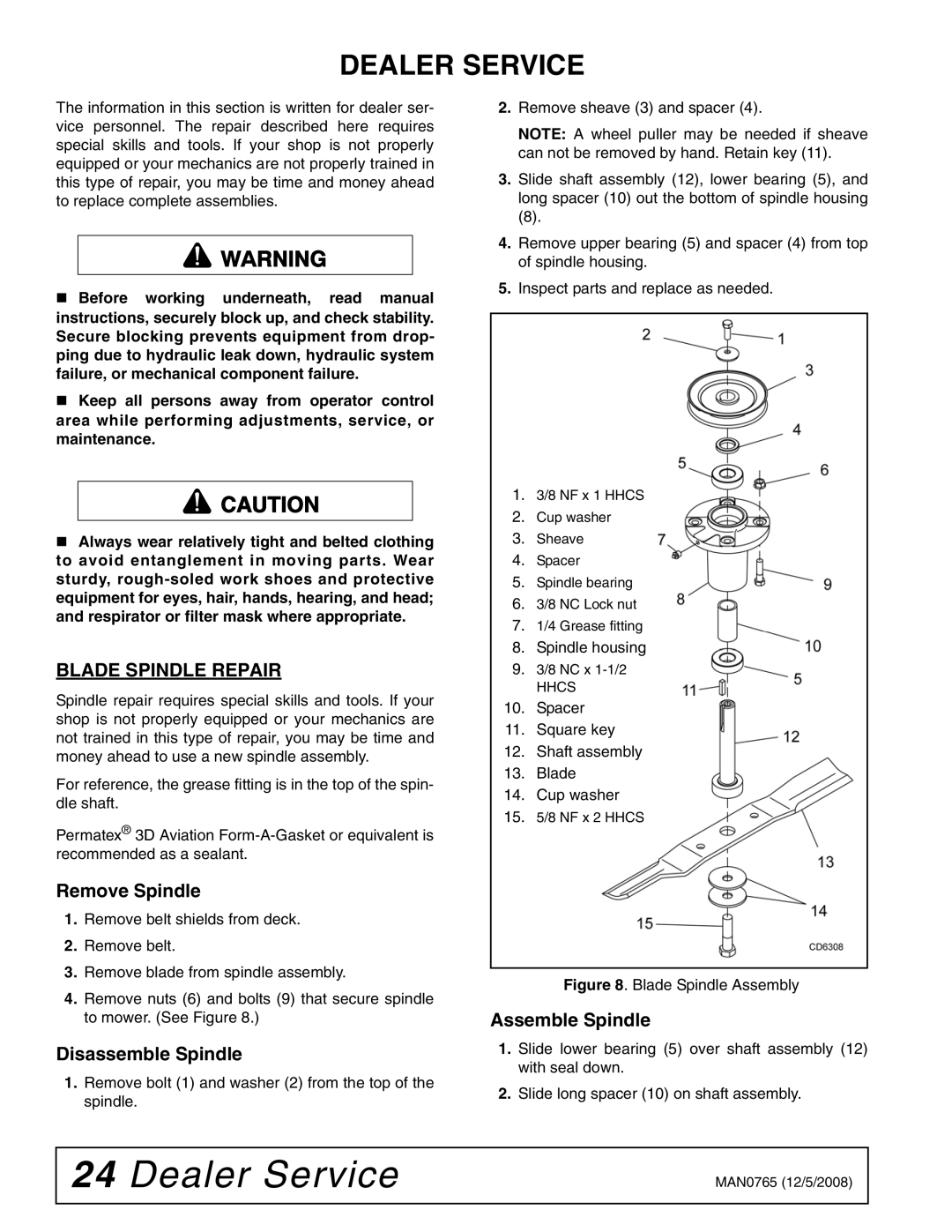

4.Remove nuts (6) and bolts (9) that secure spindle to mower. (See Figure 8.)

Disassemble Spindle

1.Remove bolt (1) and washer (2) from the top of the spindle.

2.Remove sheave (3) and spacer (4).

NOTE: A wheel puller may be needed if sheave can not be removed by hand. Retain key (11).

3.Slide shaft assembly (12), lower bearing (5), and long spacer (10) out the bottom of spindle housing

(8).

4.Remove upper bearing (5) and spacer (4) from top of spindle housing.

5.Inspect parts and replace as needed.

1.3/8 NF x 1 HHCS

2.Cup washer

3.Sheave

4.Spacer

5.Spindle bearing

6.3/8 NC Lock nut

7.1/4 Grease fitting

8.Spindle housing

9.3/8 NC x

HHCS

10.Spacer

11.Square key

12.Shaft assembly

13.Blade

14.Cup washer

15.5/8 NF x 2 HHCS

Figure 8. Blade Spindle Assembly

Assemble Spindle

1.Slide lower bearing (5) over shaft assembly (12) with seal down.

2.Slide long spacer (10) on shaft assembly.

24 Dealer Service | MAN0765 (12/5/2008) |

|

|