M1107 Bench grinder

Shop Preparation

SET UP

•Working Clearances: Consider existing and anticipated needs, size of material to be processed through the machine, and space for other machinery when establishing a location for your new machine.

•Lighting: Lighting should be bright enough to eliminate shadow and prevent eye strain.

•Electrical: Electrical circuits must be dedicated or large enough to handle amperage requirements. Outlets must be located near each machine, so power or extension cords are clear of

Mounting

The bench grinder must be mounted to a workbench to avoid accidental tipping. If you intend on using the grind- er for portable applications, mount it to a heavy plywood base (at least 1" thick) that is wide enough to prevent tipping or rocking during use, then clamp the plywood base to the workbench or table.

To mount the bench grinder, do these steps:

1.Determine the surface or object to which you will mount your grinder, and obtain the needed hard- ware for your mounting application.

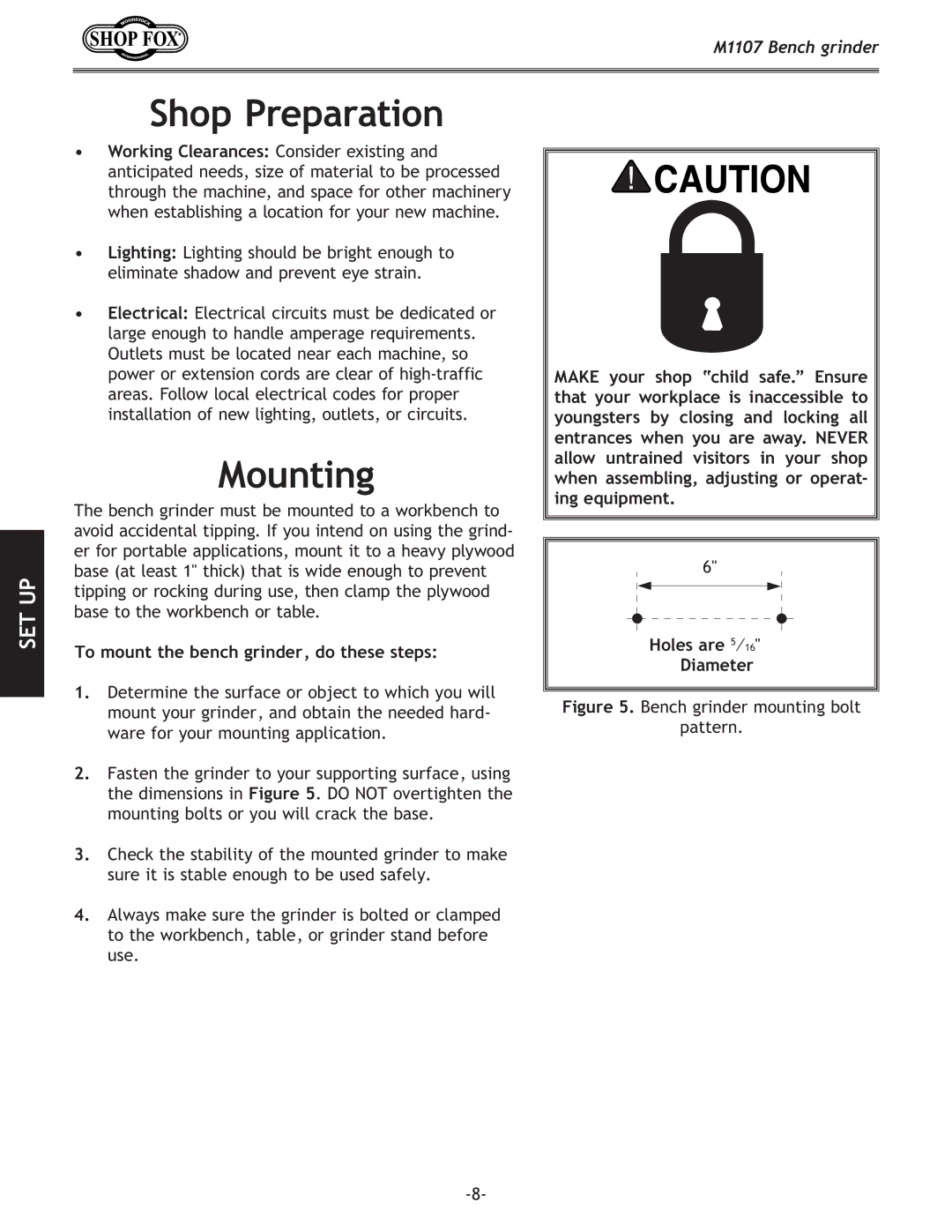

2.Fasten the grinder to your supporting surface, using the dimensions in Figure 5. DO NOT overtighten the mounting bolts or you will crack the base.

3.Check the stability of the mounted grinder to make sure it is stable enough to be used safely.

4.Always make sure the grinder is bolted or clamped to the workbench, table, or grinder stand before use.

MAKE your shop “child safe.” Ensure that your workplace is inaccessible to youngsters by closing and locking all entrances when you are away. NEVER allow untrained visitors in your shop when assembling, adjusting or operat- ing equipment.

6"

Holes are 5⁄16"

Diameter