Model W1828 (For Machines Mfg. Since 4/11)

OPERATIONS

Choosing Sandpaper

The Model W1828 uses a 12" adhesive-backed sanding disc.

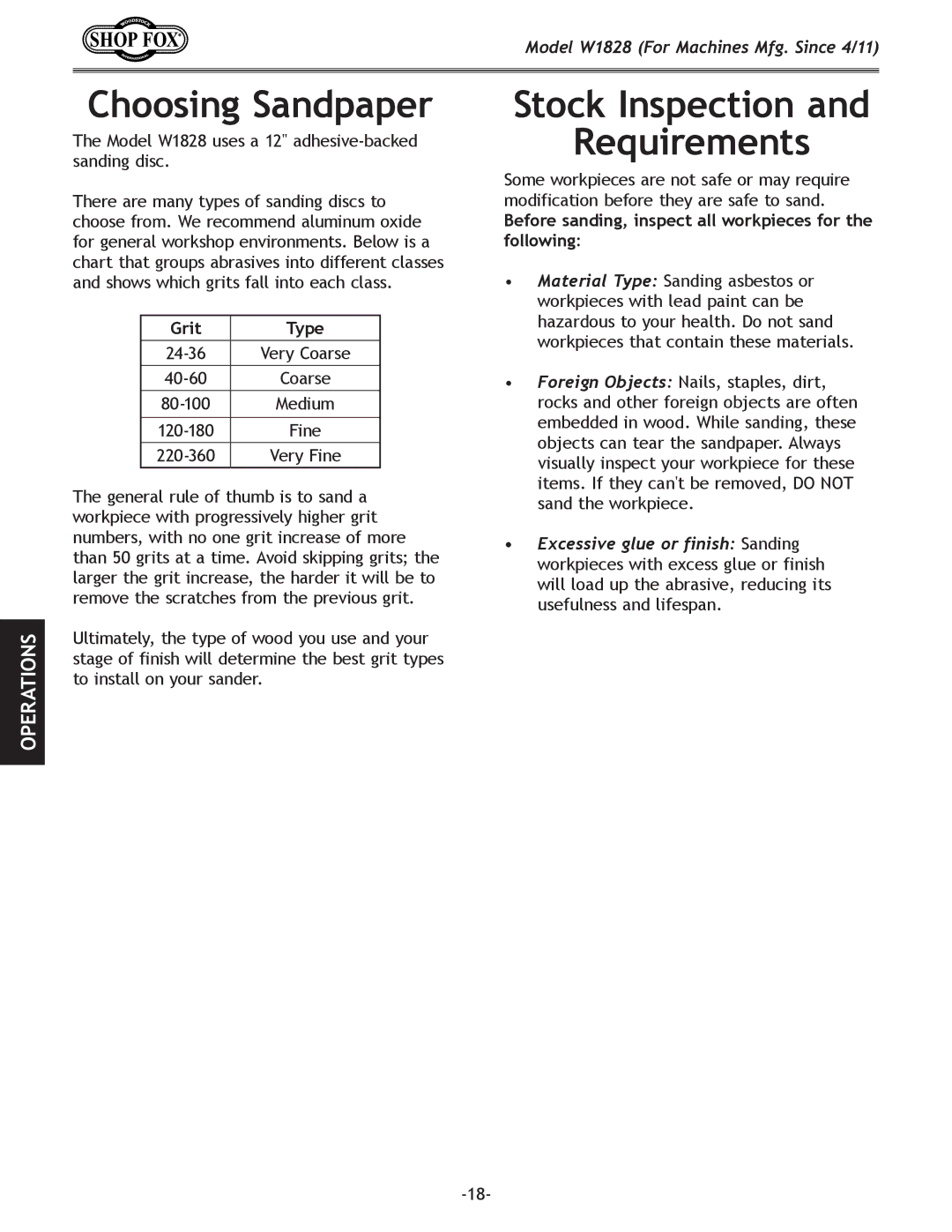

There are many types of sanding discs to choose from. We recommend aluminum oxide for general workshop environments. Below is a chart that groups abrasives into different classes and shows which grits fall into each class.

Grit | Type |

Very Coarse | |

Coarse | |

Medium | |

|

|

Fine | |

Very Fine |

The general rule of thumb is to sand a workpiece with progressively higher grit numbers, with no one grit increase of more than 50 grits at a time. Avoid skipping grits; the larger the grit increase, the harder it will be to remove the scratches from the previous grit.

Ultimately, the type of wood you use and your stage of finish will determine the best grit types to install on your sander.

Stock Inspection and

Requirements

Some workpieces are not safe or may require modification before they are safe to sand.

Before sanding, inspect all workpieces for the following:

•Material Type: Sanding asbestos or workpieces with lead paint can be hazardous to your health. Do not sand workpieces that contain these materials.

•Foreign Objects: Nails, staples, dirt, rocks and other foreign objects are often embedded in wood. While sanding, these objects can tear the sandpaper. Always visually inspect your workpiece for these items. If they can't be removed, DO NOT sand the workpiece.

•Excessive glue or finish: Sanding workpieces with excess glue or finish will load up the abrasive, reducing its usefulness and lifespan.