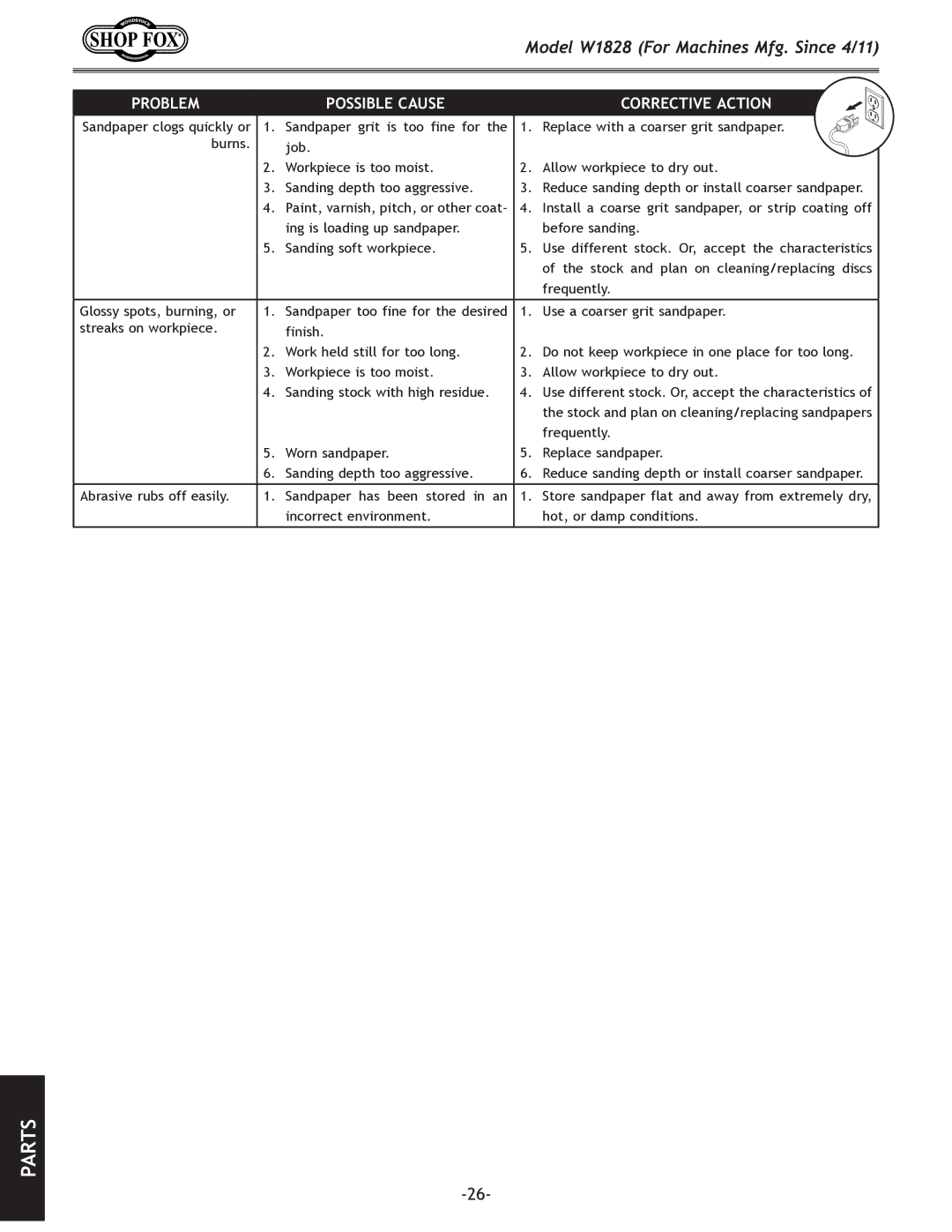

Model W1828 (For Machines Mfg. Since 4/11)

PROBLEM |

| POSSIBLE CAUSE |

| corrective action | ||

Sandpaper clogs quickly or | 1. | Sandpaper grit is too fine for the | 1. | Replace with a coarser grit sandpaper. |

|

|

| ||||||

| ||||||

burns. |

| job. |

|

|

|

|

| 2. | Workpiece is too moist. | 2. | Allow workpiece to dry out. | ||

| 3. | Sanding depth too aggressive. | 3. | Reduce sanding depth or install coarser sandpaper. | ||

| 4. | Paint, varnish, pitch, or other coat- | 4. | Install a coarse grit sandpaper, or strip coating off | ||

|

| ing is loading up sandpaper. |

| before sanding. | ||

| 5. | Sanding soft workpiece. | 5. | Use different stock. Or, accept the characteristics | ||

|

|

|

| of the stock and plan on cleaning/replacing discs | ||

|

|

|

| frequently. | ||

|

|

|

|

|

|

|

Glossy spots, burning, or | 1. | Sandpaper too fine for the desired | 1. | Use a coarser grit sandpaper. | ||

streaks on workpiece. |

| finish. |

|

|

|

|

| 2. | Work held still for too long. | 2. | Do not keep workpiece in one place for too long. | ||

| 3. | Workpiece is too moist. | 3. | Allow workpiece to dry out. | ||

| 4. | Sanding stock with high residue. | 4. | Use different stock. Or, accept the characteristics of | ||

|

|

|

| the stock and plan on cleaning/replacing sandpapers | ||

|

|

|

| frequently. | ||

| 5. | Worn sandpaper. | 5. | Replace sandpaper. | ||

| 6. | Sanding depth too aggressive. | 6. | Reduce sanding depth or install coarser sandpaper. | ||

Abrasive rubs off easily. | 1. | Sandpaper has been stored in an | 1. | Store sandpaper flat and away from extremely dry, | ||

|

| incorrect environment. |

| hot, or damp conditions. | ||

|

|

|

|

|

|

|

PARTS