OPERATING INSTRUCTIONS

1. | Right | ||||||||

| standing at the rear of the seeder/spreader and | ||||||||

| facing in the direction of travel of the tractor. | ||||||||

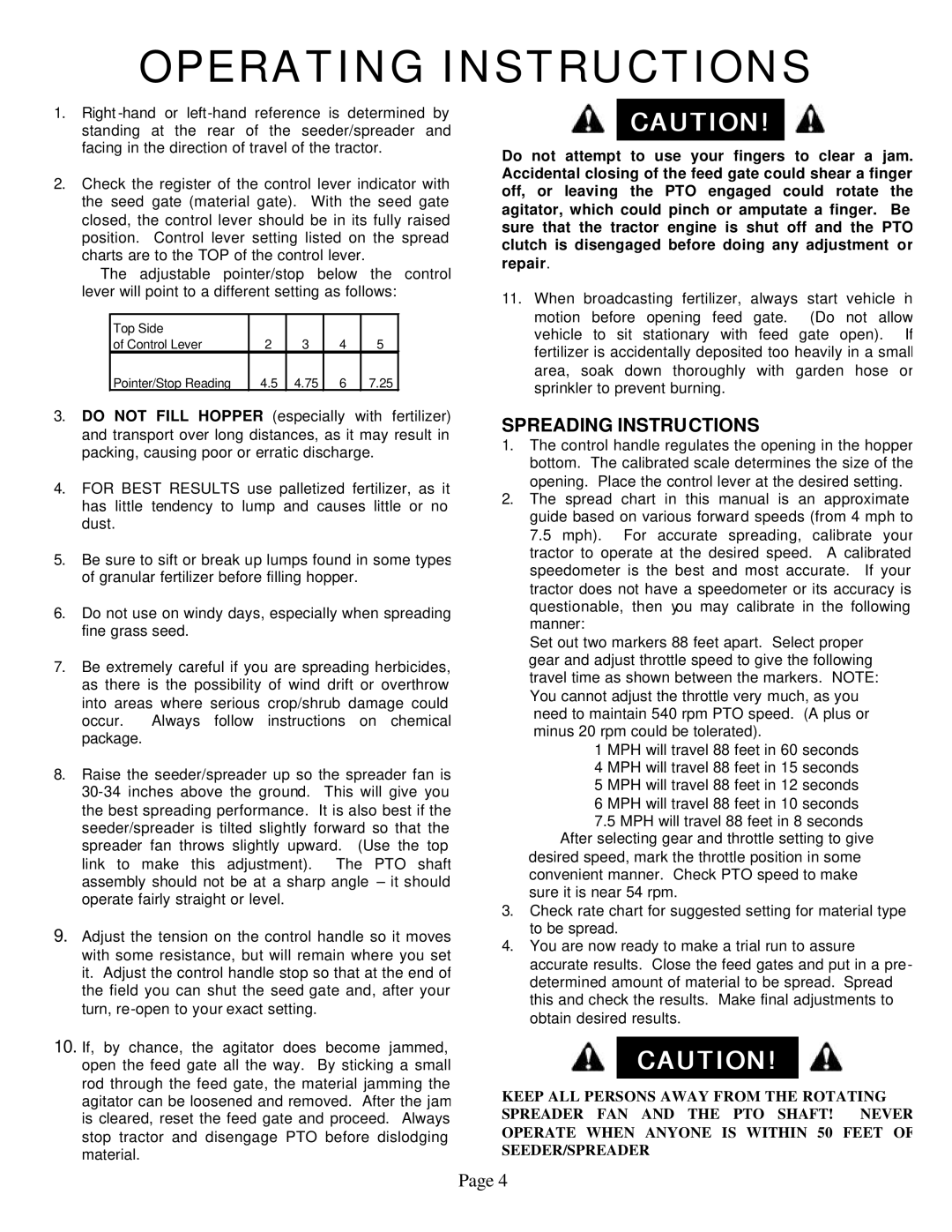

2. | Check the register of the control lever indicator with | ||||||||

| the seed gate (material gate). With the seed gate | ||||||||

| closed, the control lever should be in its fully raised | ||||||||

| position. Control lever setting listed on the spread | ||||||||

| charts are to the TOP of the control lever. |

|

| ||||||

| The adjustable pointer/stop below the control | ||||||||

| lever will point to a different setting as follows: | ||||||||

|

|

|

|

|

|

|

|

| |

|

| Top Side |

|

|

|

|

|

| |

|

| of Control Lever | 2 | 3 | 4 |

| 5 |

| |

|

| Pointer/Stop Reading | 4.5 | 4.75 | 6 |

| 7.25 |

| |

3. | DO NOT FILL HOPPER (especially with fertilizer) | ||||||||

| and transport over long distances, as it may result in | ||||||||

| packing, causing poor or erratic discharge. | ||||||||

4. | FOR BEST RESULTS use palletized fertilizer, as it | ||||||||

| has little tendency to lump and causes little or no | ||||||||

| dust. |

|

|

|

|

|

|

| |

5. | Be sure to sift or break up lumps found in some types | ||||||||

| of granular fertilizer before filling hopper. |

|

| ||||||

6. | Do not use on windy days, especially when spreading | ||||||||

| fine grass seed. |

|

|

|

|

|

| ||

7. | Be extremely careful if you are spreading herbicides, | ||||||||

| as there is the possibility of wind drift or overthrow | ||||||||

| into areas where serious crop/shrub damage could | ||||||||

| occur. | Always follow instructions on chemical | |||||||

| package. |

|

|

|

|

|

|

| |

8. | Raise the seeder/spreader up so the spreader fan is | ||||||||

| |||||||||

| the best spreading performance. It is also best if the | ||||||||

| seeder/spreader is tilted slightly forward so that the | ||||||||

| spreader fan throws slightly upward. (Use the top | ||||||||

| link to make this adjustment). The PTO shaft | ||||||||

| assembly should not be at a sharp angle – it should | ||||||||

| operate fairly straight or level. |

|

|

|

|

| |||

9. | Adjust the tension on the control handle so it moves | ||||||||

| with some resistance, but will remain where you set | ||||||||

| it. Adjust the control handle stop so that at the end of | ||||||||

| the field you can shut the seed gate and, after your | ||||||||

| turn, |

|

|

|

| ||||

10. | If, by chance, the agitator does become jammed, | ||||||||

| open the feed gate all the way. By sticking a small | ||||||||

rod through the feed gate, the material jamming the agitator can be loosened and removed. After the jam is cleared, reset the feed gate and proceed. Always stop tractor and disengage PTO before dislodging material.

![]()

![]() CAUTION!

CAUTION!

Do not attempt to use your fingers to clear a jam. Accidental closing of the feed gate could shear a finger off, or leaving the PTO engaged could rotate the agitator, which could pinch or amputate a finger. Be sure that the tractor engine is shut off and the PTO clutch is disengaged before doing any adjustment or repair.

11.When broadcasting fertilizer, always start vehicle in motion before opening feed gate. (Do not allow vehicle to sit stationary with feed gate open). If fertilizer is accidentally deposited too heavily in a small area, soak down thoroughly with garden hose or sprinkler to prevent burning.

SPREADING INSTRUCTIONS

1.The control handle regulates the opening in the hopper bottom. The calibrated scale determines the size of the opening. Place the control lever at the desired setting.

2.The spread chart in this manual is an approximate guide based on various forward speeds (from 4 mph to

7.5mph). For accurate spreading, calibrate your tractor to operate at the desired speed. A calibrated speedometer is the best and most accurate. If your tractor does not have a speedometer or its accuracy is questionable, then you may calibrate in the following manner:

Set out two markers 88 feet apart. Select proper gear and adjust throttle speed to give the following travel time as shown between the markers. NOTE: You cannot adjust the throttle very much, as you need to maintain 540 rpm PTO speed. (A plus or minus 20 rpm could be tolerated).

1 MPH will travel 88 feet in 60 seconds

4 MPH will travel 88 feet in 15 seconds

5 MPH will travel 88 feet in 12 seconds

6 MPH will travel 88 feet in 10 seconds

7.5MPH will travel 88 feet in 8 seconds After selecting gear and throttle setting to give

desired speed, mark the throttle position in some convenient manner. Check PTO speed to make sure it is near 54 rpm.

3.Check rate chart for suggested setting for material type to be spread.

4.You are now ready to make a trial run to assure accurate results. Close the feed gates and put in a pre- determined amount of material to be spread. Spread this and check the results. Make final adjustments to obtain desired results.

CAUTION!

KEEP ALL PERSONS AWAY FROM THE ROTATING

SPREADER FAN AND THE PTO SHAFT! NEVER OPERATE WHEN ANYONE IS WITHIN 50 FEET OF SEEDER/SPREADER

Page 4