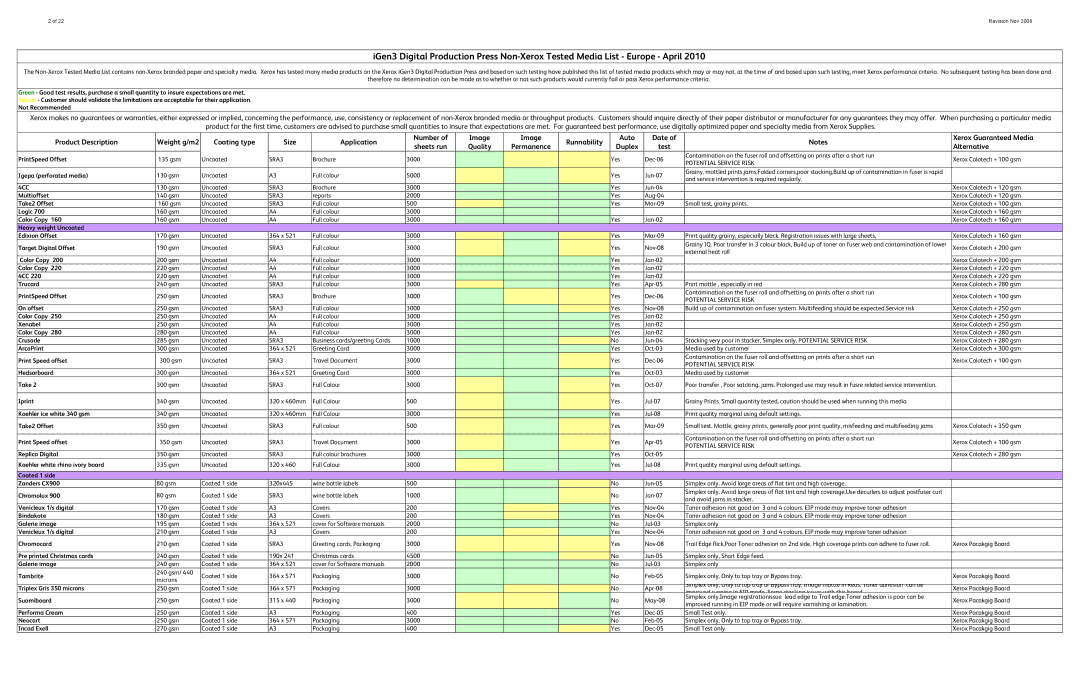

| Product Description | Weight g/m2 | Coating type | Size | Application | Number of | Image | Image | Runnability | Auto | Date of | Notes | Xerox Guaranteed Media |

| sheets run | Quality | Permanence | Duplex | test | Alternative |

| | | | | | | |

| PrintSpeed Offset | 135 gsm | Uncoated | SRA3 | Brochure | 3000 | | | | Yes | Dec-06 | Contamination on the fuser roll and offsetting on prints after a short run | Xerox Colotech + 100 gsm |

| | | | POTENTIAL SERVICE RISK |

| | | | | | | | | | | | |

| Igepa (perforated media) | 130 gsm | Uncoated | A3 | Full colour | 5000 | | | | Yes | Jun-07 | Grainy, mottled prints,jams,Folded corners,poor stacking,Build up of contamination in fuser is rapid | |

| | | | and service intervention is required regularly. | |

| | | | | | | | | | | | |

| 4CC | 130 gsm | Uncoated | SRA3 | Brochure | 3000 | | | | Yes | Jun-04 | | Xerox Colotech + 120 gsm |

| Multioffset | 140 gsm | Uncoated | SRA3 | reports | 2000 | | | | Yes | Aug-04 | | Xerox Colotech + 120 gsm |

| Take2 Offset | 160 gsm | Uncoated | SRA3 | Full colour | 500 | | | | Yes | Mar-09 | Small test, grainy prints. | Xerox Colotech + 100 gsm |

| Logic 700 | 160 gsm | Uncoated | A4 | Full colour | 3000 | | | | | | | Xerox Colotech + 160 gsm |

| Color Copy 160 | 160 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 160 gsm |

| Heavy weight Uncoated | | | | | | | | | | | | |

| Edixion Offset | 170 gsm | Uncoated | 364 x 521 | Full colour | 3000 | | | | Yes | Mar-09 | Print quality grainy, especially black. Registration issues with large sheets, | Xerox Colotech + 160 gsm |

| Target Digital Offset | 190 gsm | Uncoated | SRA3 | Full colour | 3000 | | | | Yes | Nov-08 | Grainy IQ. Poor transfer in 3 colour black, Build up of toner on fuser web and contamination of lower | Xerox Colotech + 200 gsm |

| | | | external heat roll |

| | | | | | | | | | | | |

| Color Copy 200 | 200 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 200 gsm |

| Color Copy 220 | 220 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 220 gsm |

| 4CC 220 | 220 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 220 gsm |

| Trucard | 240 gsm | Uncoated | SRA3 | Full colour | 3000 | | | | Yes | Apr-05 | Print mottle , especially in red | Xerox Colotech + 280 gsm |

| PrintSpeed Offset | 250 gsm | Uncoated | SRA3 | Brochure | 3000 | | | | Yes | Dec-06 | Contamination on the fuser roll and offsetting on prints after a short run | Xerox Colotech + 100 gsm |

| | | | POTENTIAL SERVICE RISK |

| | | | | | | | | | | | |

| On offset | 250 gsm | Uncoated | SRA3 | Full colour | 3000 | | | | Yes | Nov-08 | Build up of contamination on fuser system. Multifeeding should be expected.Service risk | Xerox Colotech + 250 gsm |

| Color Copy 250 | 250 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 250 gsm |

| Xenabel | 250 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 250 gsm |

| Color Copy 280 | 280 gsm | Uncoated | A4 | Full colour | 3000 | | | | Yes | Jan-02 | | Xerox Colotech + 280 gsm |

| Crusade | 285 gsm | Uncoated | SRA3 | Business cards/greeting Cards | 1000 | | | | No | Jun-04 | Stacking very poor in stacker, Simplex only. POTENTIAL SERVICE RISK | Xerox Colotech + 280 gsm |

| ArcoPrint | 300 gsm | Uncoated | 364 x 521 | Greeting Card | 3000 | | | | Yes | Oct-03 | Media used by customer | Xerox Colotech + 300 gsm |

| Print Speed offset | 300 gsm | Uncoated | SRA3 | Travel Document | 3000 | | | | Yes | Dec-06 | Contamination on the fuser roll and offsetting on prints after a short run | Xerox Colotech + 100 gsm |

| | | | POTENTIAL SERVICE RISK |

| | | | | | | | | | | | |

| Hedsorboard | 300 gsm | Uncoated | 364 x 521 | Greeting Card | 3000 | | | | Yes | Oct-03 | Media used by customer | |

| Take 2 | 300 gsm | Uncoated | SRA3 | Full Colour | 3000 | | | | Yes | Oct-07 | Poor transfer , Poor satcking, jams. Prolonged use may result in fusre related service intervention. | |

| | | | | | | | | | | | | |

| Iprint | 340 gsm | Uncoated | 320 x 460mm | Full Colour | 500 | | | | Yes | Jul-07 | Grainy Prints. Small quantity tested, caution should be used when running this media | |

| | | | | | | | | | | | | |

| Koehler ice white 340 gsm | 340 gsm | Uncoated | 320 x 460mm | Full Colour | 3000 | | | | Yes | Jul-08 | Print quality marginal using default settings. | |

| Take2 Offset | 350 gsm | Uncoated | SRA3 | Full colour | 500 | | | | Yes | Mar-09 | Small test. Mottle, grainy prints, generally poor print quality, misfeeding and multifeeding jams | Xerox Colotech + 350 gsm |

| | | | | | | | | | | | | |

| Print Speed offset | 350 gsm | Uncoated | SRA3 | Travel Document | 3000 | | | | Yes | Apr-05 | Contamination on the fuser roll and offsetting on prints after a short run | Xerox Colotech + 100 gsm |

| | | | POTENTIAL SERVICE RISK |

| | | | | | | | | | | | |

| Replica Digital | 350 gsm | Uncoated | SRA3 | Full colour brochures | 3000 | | | | Yes | Oct-05 | | Xerox Colotech + 280 gsm |

| Koehler white rhino ivory board | 335 gsm | Uncoated | 320 x 460 | Full Colour | 3000 | | | | Yes | Jul-08 | Print quality marginal using default settings. | |

| | | | | | | | | | | | | |

| Coated 1 side | | | | | | | | | | | | |

| Zanders CX900 | 80 gsm | Coated 1 side | 320x445 | wine bottle labels | 500 | | | | No | Jun-05 | Simplex only. Avoid large areas of flat tint and high coverage. | |

| Chromolux 900 | 80 gsm | Coated 1 side | SRA3 | wine bottle labels | 1000 | | | | No | Jan-07 | Simplex only. Avoid large areas of flat tint and high coverage.Use decurlers to adjust postfuser curl | |

| | | | and avoid jams in stacker. | |

| | | | | | | | | | | | |

| Venicleux 1/s digital | 170 gsm | Coated 1 side | A3 | Covers | 200 | | | | Yes | Nov-04 | Toner adhesion not good on 3 and 4 colours. EIP mode may improve toner adhesion | |

| Bindakote | 180 gsm | Coated 1 side | A3 | Covers | 200 | | | | Yes | Nov-04 | Toner adhesion not good on 3 and 4 colours. EIP mode may improve toner adhesion | |

| Galerie image | 195 gsm | Coated 1 side | 364 x 521 | cover for Software manuals | 2000 | | | | No | Jul-03 | Simplex only | |

| Venicleux 1/s digital | 210 gsm | Coated 1 side | A3 | Covers | 200 | | | | Yes | Nov-04 | Toner adhesion not good on 3 and 4 colours. EIP mode may improve toner adhesion | |

| Chromocard | 210 gsm | Coated 1 side | SRA3 | Greeting cards, Packaging | 3000 | | | | Yes | Nov-08 | Trail Edge flick,Poor Toner adhesion on 2nd side, High coverage prints can adhere to fuser roll. | Xerox Pacakgig Board |

| | | | | | | | | | | | | |

| Pre printed Christmas cards | 240 gsm | Coated 1 side | 190x 241 | Christmas cards | 4500 | | | | No | Jun-05 | Simplex only, Short Edge feed. | |

| Galerie image | 240 gsm | Coated 1 side | 364 x 521 | cover for Software manuals | 2000 | | | | No | Jul-03 | Simplex only | |

| Tambrite | 240 gsm/ 440 | Coated 1 side | 364 x 571 | Packaging | 3000 | | | | No | Feb-05 | Simplex only, Only to top tray or Bypass tray. | Xerox Pacakgig Board |

| microns | | | |

| | | | | | | | | | | Simplex only, Only to top tray or Bypass tray. Image mottle in Reds. Toner adhesion can be | |

| Triplex Gris 350 microns | 250 gsm | Coated 1 side | 364 x 571 | Packaging | 3000 | | | | No | Apr-08 | Xerox Pacakgig Board |

| | | | improved running in EIP mode Some stacking issues with this board |

| Suomiboard | 250 gsm | Coated 1 side | 315 x 440 | Packaging | 3000 | | | | No | May-08 | Simplex only.Image registrationissue lead edge to Trail edge.Toner adhesion is poor can be | Xerox Pacakgig Board |

| | | | improved running in EIP mode or will require varnishing or lamination. |

| | | | | | | | | | | | |

| Performa Cream | 250 gsm | Coated 1 side | A3 | Packaging | 400 | | | | Yes | Dec-05 | Small Test only. | Xerox Pacakgig Board |

| Neocart | 250 gsm | Coated 1 side | 364 x 571 | Packaging | 3000 | | | | No | Feb-05 | Simplex only, Only to top tray or Bypass tray. | Xerox Pacakgig Board |

| Incad Exell | 270 gsm | Coated 1 side | A3 | Packaging | 400 | | | | Yes | Dec-05 | Small Test only. | Xerox Pacakgig Board |