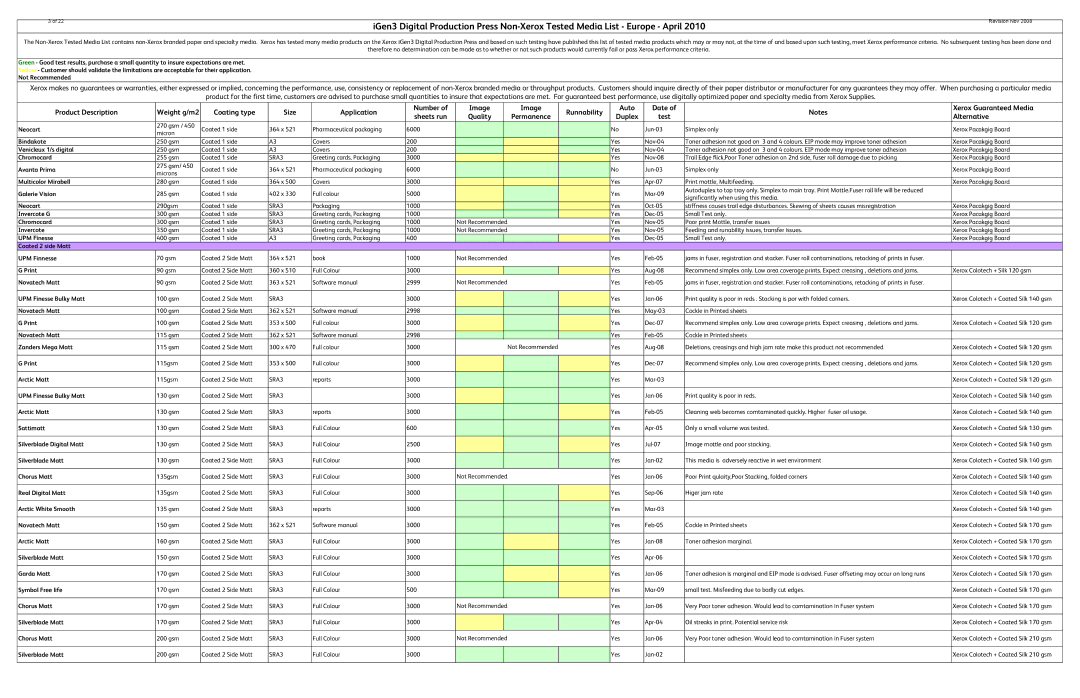

Product Description | Weight g/m2 | Coating type | Size | Application | Number of | Image | | Image | Runnability | Auto | Date of | Notes | Xerox Guaranteed Media |

sheets run | Quality | | Permanence | Duplex | test | Alternative |

| | | | | | | |

Neocart | 270 gsm / 450 | Coated 1 side | 364 x 521 | Pharmaceutical packaging | 6000 | | | | | No | Jun-03 | Simplex only | Xerox Pacakgig Board |

micron | | | | |

| | | | | | | | | | | | |

Bindakote | 250 gsm | Coated 1 side | A3 | Covers | 200 | | | | | Yes | Nov-04 | Toner adhesion not good on 3 and 4 colours. EIP mode may improve toner adhesion | Xerox Pacakgig Board |

Venicleux 1/s digital | 250 gsm | Coated 1 side | A3 | Covers | 200 | | | | | Yes | Nov-04 | Toner adhesion not good on 3 and 4 colours. EIP mode may improve toner adhesion | Xerox Pacakgig Board |

Chromocard | 255 gsm | Coated 1 side | SRA3 | Greeting cards, Packaging | 3000 | | | | | Yes | Nov-08 | Trail Edge flick,Poor Toner adhesion on 2nd side, fuser roll damage due to picking | Xerox Pacakgig Board |

Avanta Prima | 275 gsm/ 450 | Coated 1 side | 364 x 521 | Pharmaceutical packaging | 6000 | | | | | No | Jun-03 | Simplex only | Xerox Pacakgig Board |

microns | | | | |

| | | | | | | | | | | | |

Multicolor Mirabell | 280 gsm | Coated 1 side | 364 x 500 | Covers | 3000 | | | | | Yes | Apr-07 | Print mottle, Multifeeding. | Xerox Pacakgig Board |

Galerie Vision | 285 gsm | Coated 1 side | 402 x 330 | Full colour | 5000 | | | | | Yes | Mar-09 | Autoduplex to top tray only. Simplex to main tray. Print Mottle.Fuser roll life will be reduced | |

| | | | significantly when using this media. | |

| | | | | | | | | | | | |

Neocart | 290gsm | Coated 1 side | SRA3 | Packaging | 1000 | | | | | Yes | Oct-05 | stiffness causes trail edge disturbances. Skewing of sheets causes misregistration | Xerox Pacakgig Board |

Invercote G | 300 gsm | Coated 1 side | SRA3 | Greeting cards, Packaging | 1000 | | | | | Yes | Dec-05 | Small Test only. | Xerox Pacakgig Board |

Chromocard | 300 gsm | Coated 1 side | SRA3 | Greeting cards, Packaging | 1000 | Not Recommended | | | | Yes | Nov-05 | Poor print Mottle, transfer issues | Xerox Pacakgig Board |

Invercote | 350 gsm | Coated 1 side | SRA3 | Greeting cards, Packaging | 1000 | Not Recommended | | | Yes | Nov-05 | Feeding and runability issues, transfer issues. | Xerox Pacakgig Board |

UPM Finesse | 400 gsm | Coated 1 side | A3 | Greeting cards, Packaging | 400 | | | | | Yes | Dec-05 | Small Test only. | Xerox Pacakgig Board |

Coated 2 side Matt | | | | | | | | | | | | | |

UPM Finnesse | 70 gsm | Coated 2 Side Matt | 364 x 521 | book | 1000 | Not Recommended | | | Yes | Feb-05 | jams in fuser, registration and stacker. Fuser roll contaminations, retacking of prints in fuser. | |

| | | | | | | | | | | | | |

G Print | 90 gsm | Coated 2 Side Matt | 360 x 510 | Full Colour | 3000 | | | | | Yes | Aug-08 | Recommend simplex only. Low area coverage prints. Expect creasing , deletions and jams. | Xerox Colotech + Silk 120 gsm |

Novatech Matt | 90 gsm | Coated 2 Side Matt | 363 x 521 | Software manual | 2999 | Not Recommended | | | Yes | Feb-05 | jams in fuser, registration and stacker. Fuser roll contaminations, retacking of prints in fuser. | |

| | | | | | | | | | | | | |

UPM Finesse Bulky Matt | 100 gsm | Coated 2 Side Matt | SRA3 | | 3000 | | | | | Yes | Jan-06 | Print quality is poor in reds . Stacking is por with folded corners. | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Novatech Matt | 100 gsm | Coated 2 Side Matt | 362 x 521 | Software manual | 2998 | | | | | Yes | May-03 | Cockle in Printed sheets | |

G Print | 100 gsm | Coated 2 Side Matt | 353 x 500 | Full colour | 3000 | | | | | Yes | Dec-07 | Recommend simplex only. Low area coverage prints. Expect creasing , deletions and jams. | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Novatech Matt | 115 gsm | Coated 2 Side Matt | 362 x 521 | Software manual | 2998 | | | | | Yes | Feb-05 | Cockle in Printed sheets | |

Zanders Mega Matt | 115 gsm | Coated 2 Side Matt | 300 x 470 | Full colour | 3000 | | | Not Recommended | | Yes | Aug-08 | Deletions, creasings and high jam rate make this product not recommended | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

G Print | 115gsm | Coated 2 Side Matt | 353 x 500 | Full colour | 3000 | | | | | Yes | Dec-07 | Recommend simplex only. Low area coverage prints. Expect creasing , deletions and jams. | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Arctic Matt | 115gsm | Coated 2 Side Matt | SRA3 | reports | 3000 | | | | | Yes | Mar-03 | | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

UPM Finesse Bulky Matt | 130 gsm | Coated 2 Side Matt | SRA3 | | 3000 | | | | | Yes | Jan-06 | Print quality is poor in reds. | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Arctic Matt | 130 gsm | Coated 2 Side Matt | SRA3 | reports | 3000 | | | | | Yes | Feb-05 | Cleaning web becomes comtaminated quickly. Higher fuser oil usage. | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Sattimatt | 130 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 600 | | | | | Yes | Apr-05 | Only a small volume was tested. | Xerox Colotech + Coated Silk 130 gsm |

| | | | | | | | | | | | | |

Silverblade Digital Matt | 130 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 2500 | | | | | Yes | Jul-07 | Image mottle and poor stacking. | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Silverblade Matt | 130 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-02 | This media is adversely reactive in wet environment | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Chorus Matt | 135gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Jan-06 | Poor Print qulaity,Poor Stacking, folded corners | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Real Digital Matt | 135gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Sep-06 | Higer jam rate | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Arctic White Smooth | 135 gsm | Coated 2 Side Matt | SRA3 | reports | 3000 | | | | | Yes | Mar-03 | | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Novatech Matt | 150 gsm | Coated 2 Side Matt | 362 x 521 | Software manual | 3000 | | | | | Yes | Feb-05 | Cockle in Printed sheets | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Arctic Matt | 160 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-08 | Toner adhesion marginal. | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Silverblade Matt | 150 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Apr-06 | | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Garda Matt | 170 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-06 | Toner adhesion is marginal and EIP mode is advised. Fuser offseting may occur on long runs | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Symbol Free life | 170 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 500 | | | | | Yes | Mar-09 | small test. Misfeeding due to badly cut edges. | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Chorus Matt | 170 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Jan-06 | Very Poor toner adhesion. Would lead to comtamination in Fuser system | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Silverblade Matt | 170 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Apr-04 | Oil streaks in print. Potential service risk | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Chorus Matt | 200 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Jan-06 | Very Poor toner adhesion. Would lead to comtamination in Fuser system | Xerox Colotech + Coated Silk 210 gsm |

| | | | | | | | | | | | | |

Silverblade Matt | 200 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-02 | | Xerox Colotech + Coated Silk 210 gsm |

| | | | | | | | | | | | | |