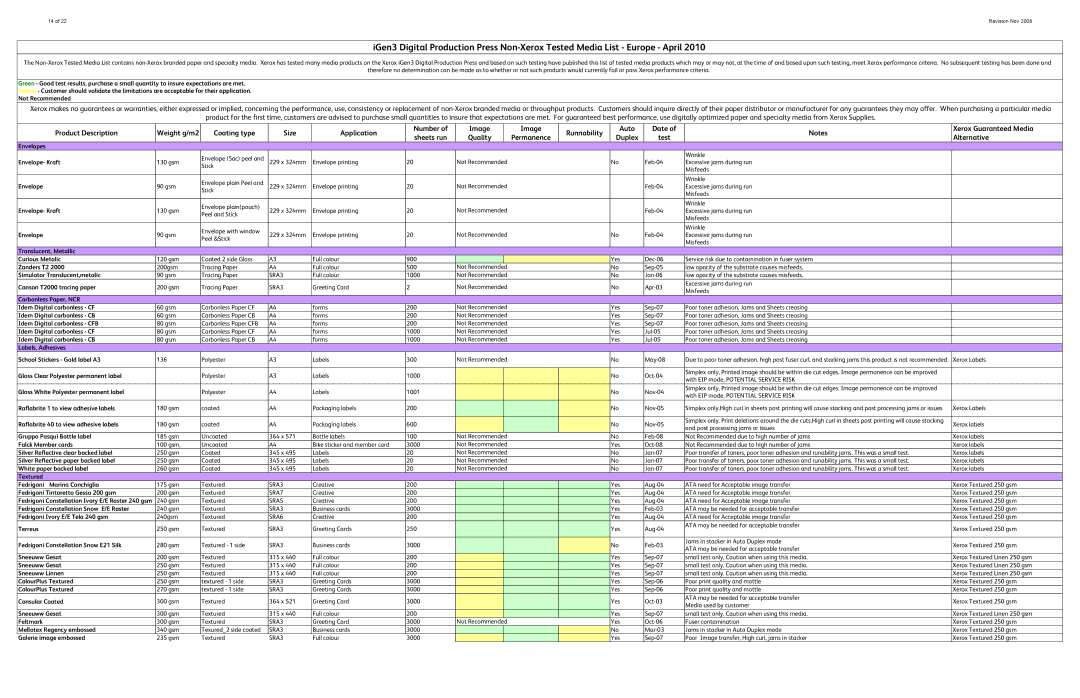

Envelope- Kraft | | Envelope (Sac) peel and | | | | Not Recommended | | | Wrinkle | |

130 gsm | 229 x 324mm | Envelope printing | 20 | No | Feb-04 | Excessive jams during run | |

| | Stick | | | | | | | | | Misfeeds | |

| | | | | | | | | | | |

Envelope | | Envelope plain Peel and | | | | Not Recommended | | | Wrinkle | |

90 gsm | 229 x 324mm | Envelope printing | 20 | | Feb-04 | Excessive jams during run | |

Stick | | |

| | | | | | | | | | Misfeeds | |

| | | | | | | | | | | |

| | | | | | | | | | | | |

Envelope- Kraft | | Envelope plain(pouch) | | | | Not Recommended | | | Wrinkle | |

130 gsm | 229 x 324mm | Envelope printing | 20 | | Feb-04 | Excessive jams during run | |

Peel and Stick | | |

| | | | | | | | | | Misfeeds | |

| | | | | | | | | | | |

| | | | | | | | | | | | |

Envelope | | Envelope with window | | | | Not Recommended | | | Wrinkle | |

90 gsm | 229 x 324mm | Envelope printing | 20 | No | Feb-04 | Excessive jams during run | |

Peel &Stick | |

| | | | | | | | | | Misfeeds | |

| | | | | | | | | | | |

Translucent, Metallic | | | | | | | | | | | | |

Curious Metalic | 120 gsm | Coated 2 side Gloss | A3 | Full colour | 900 | | | | Yes | Dec-06 | Service risk due to contamination in fuser system | |

Zanders T2 2000 | 200gsm | Tracing Paper | A4 | Full colour | 500 | Not Recommended | | | No | Sep-05 | low opacity of the substrate causes misfeeds. | |

Simulator Translucent,metalic | 90 gsm | Tracing Paper | SRA3 | Full colour | 1000 | Not Recommended | No | Jan-06 | low opacity of the substrate causes misfeeds. | |

Canson T2000 tracing paper | 200 gsm | Tracing Paper | SRA3 | Greeting Card | 2 | Not Recommended | No | Apr-03 | Excessive jams during run | |

Misfeeds | |

| | | | | | | | | | | |

Carbonless Paper, NCR | | | | | | | | | | | | |

Idem Digital carbonless - CF | 60 gsm | Carbonless Paper CF | A4 | forms | 200 | Not Recommended | Yes | Sep-07 | Poor toner adhesion, Jams and Sheets creasing | |

Idem Digital carbonless - CB | 60 gsm | Carbonless Paper CB | A4 | forms | 200 | Not Recommended | Yes | Sep-07 | Poor toner adhesion, Jams and Sheets creasing | |

Idem Digital carbonless - CFB | 80 gsm | Carbonless Paper CFB | A4 | forms | 200 | Not Recommended | Yes | Sep-07 | Poor toner adhesion, Jams and Sheets creasing | |

Idem Digital carbonless - CF | 80 gsm | Carbonless Paper CF | A4 | forms | 1000 | Not Recommended | Yes | Jul-05 | Poor toner adhesion, Jams and Sheets creasing | |

Idem Digital carbonless - CB | 80 gsm | Carbonless Paper CB | A4 | forms | 1000 | Not Recommended | Yes | Jul-05 | Poor toner adhesion, Jams and Sheets creasing | |

Labels, Adhesives | | | | | | | | | | | | |

School Stickers - Gold label A3 | 136 | Polyester | A3 | Labels | 300 | Not Recommended | No | May-08 | Due to poor toner adhesion, high post fuser curl, and stacking jams this product is not recommended. | Xerox Labels |

| | | | | | | | | | | | |

Gloss Clear Polyester permanent label | | Polyester | A3 | Labels | 1000 | | | | No | Oct-04 | Simplex only, Printed image should be within die cut edges. Image permanence can be improved | |

| | | | with EIP mode, POTENTIAL SERVICE RISK | |

| | | | | | | | | | | |

Gloss White Polyester permanent label | | Polyester | A4 | Labels | 1001 | | | | No | Nov-04 | Simplex only, Printed image should be within die cut edges. Image permanence can be improved | |

| | | | with EIP mode, POTENTIAL SERVICE RISK | |

| | | | | | | | | | | |

Raflabrite 1 to view adhesive labels | 180 gsm | coated | A4 | Packaging labels | 200 | | | | No | Nov-05 | Simplex only.High curl in sheets post printing will cause stacking and post processing jams or issues | Xerox Labels |

| | | | | | | | | | | | |

Raflabrite 40 to view adhesive labels | 180 gsm | coated | A4 | Packaging labels | 600 | | | | No | Nov-05 | Simplex only. Print deletions around the die cuts.High curl in sheets post printing will cause stacking | Xerox labels |

| | | and post processing jams or issues |

| | | | | | | | | | | |

Gruppo Pasqui Bottle label | 185 gsm | Uncoated | 364 x 571 | Bottle labels | 100 | Not Recommended | | | No | Feb-08 | Not Recommended due to high number of jams | Xerox labels |

Falck Member cards | 100 gsm, | Uncoated | A4 | Bike sticker and member card | 3000 | Not Recommended | Yes | Oct-08 | Not Recommended due to high number of jams | Xerox labels |

Silver Reflective clear backed label | 250 gsm | Coated | 345 x 495 | Labels | 20 | Not Recommended | No | Jan-07 | Poor transfer of toners, poor toner adhesion and runability jams. This was a small test. | Xerox labels |

Silver Reflective paper backed label | 250 gsm | Coated | 345 x 495 | Labels | 20 | Not Recommended | No | Jan-07 | Poor transfer of toners, poor toner adhesion and runability jams. This was a small test. | Xerox labels |

White paper backed label | 260 gsm | Coated | 345 x 495 | Labels | 20 | Not Recommended | No | Jan-07 | Poor transfer of toners, poor toner adhesion and runability jams. This was a small test. | Xerox labels |

Textured | | | | | | | | | | | | |

Fedrigoni Marina Conchiglia | 175 gsm | Textured | SRA3 | Creative | 200 | | | | Yes | Aug-04 | ATA need for Acceptable image transfer | Xerox Textured 250 gsm |

Fedrigoni Tintoretto Gesso 200 gsm | 200 gsm | Textured | SRA7 | Creative | 200 | | | | Yes | Aug-04 | ATA need for Acceptable image transfer | Xerox Textured 250 gsm |

Fedrigoni Constellation Ivory E/E Raster 240 gsm | 240 gsm | Textured | SRA5 | Creative | 200 | | | | Yes | Aug-04 | ATA need for Acceptable image transfer | Xerox Textured 250 gsm |

Fedrigoni Constellation Snow E/E Raster | 240 gsm | Textured | SRA3 | Business cards | 3000 | | | | Yes | Feb-03 | ATA may be needed for acceptable transfer | Xerox Textured 250 gsm |

Fedrigoni Ivory E/E Tela 240 gsm | 240gsm | Textured | SRA6 | Creative | 200 | | | | Yes | Aug-04 | ATA need for Acceptable image transfer | Xerox Textured 250 gsm |

Terreus | 250 gsm | Textured | SRA3 | Greeting Cards | 250 | | | | Yes | Aug-04 | ATA may be needed for acceptable transfer | Xerox Textured 250 gsm |

| | | |

| | | | | | | | | | | | |

Fedrigoni Constellation Snow E21 Silk | 280 gsm | Textured - 1 side | SRA3 | Business cards | 3000 | | | | No | Feb-03 | Jams in stacker in Auto Duplex mode | Xerox Textured 250 gsm |

| | | ATA may be needed for acceptable transfer |

| | | | | | | | | | | |

Sneeuww Gesat | 200 gsm | Textured | 315 x 440 | Full colour | 200 | | | | Yes | Sep-07 | small test only. Caution when using this media. | Xerox Textured Linen 250 gsm |

Sneeuww Gesat | 250 gsm | Textured | 315 x 440 | Full colour | 200 | | | | Yes | Sep-07 | small test only. Caution when using this media. | Xerox Textured Linen 250 gsm |

Sneeuww Linnen | 250 gsm | Textured | 315 x 440 | Full colour | 200 | | | | Yes | Sep-07 | small test only. Caution when using this media. | Xerox Textured Linen 250 gsm |

ColourPlus Textured | 250 gsm | textured - 1 side | SRA3 | Greeting Cards | 3000 | | | | Yes | Sep-06 | Poor print quality and mottle | Xerox Textured 250 gsm |

ColourPlus Textured | 270 gsm | textured - 1 side | SRA3 | Greeting Cards | 3000 | | | | Yes | Sep-06 | Poor print quality and mottle | Xerox Textured 250 gsm |

Consular Coated | 300 gsm | Textured | 364 x 521 | Greeting Card | 3000 | | | | Yes | Oct-03 | ATA may be needed for acceptable transfer | Xerox Textured 250 gsm |

| | | Media used by customer |

| | | | | | | | | | | |

Sneeuww Gesat | 300 gsm | Textured | 315 x 440 | Full colour | 200 | | | | Yes | Sep-07 | small test only. Caution when using this media. | Xerox Textured Linen 250 gsm |

Feltmark | 300 gsm | Textured | SRA3 | Greeting Card | 3000 | Not Recommended | | | Yes | Oct-06 | Fuser contamination | Xerox Textured 250 gsm |

Mellotex Regency embossed | 340 gsm | Texured_2 side coated | SRA3 | Business cards | 3000 | | | | No | Mar-03 | Jams in stacker in Auto Duplex mode | Xerox Textured 250 gsm |

Galerie image embossed | 235 gsm | Textured | SRA3 | Full colour | 3000 | | | | Yes | Sep-07 | Poor Image transfer, High curl, jams in stacker | Xerox Textured 250 gsm |