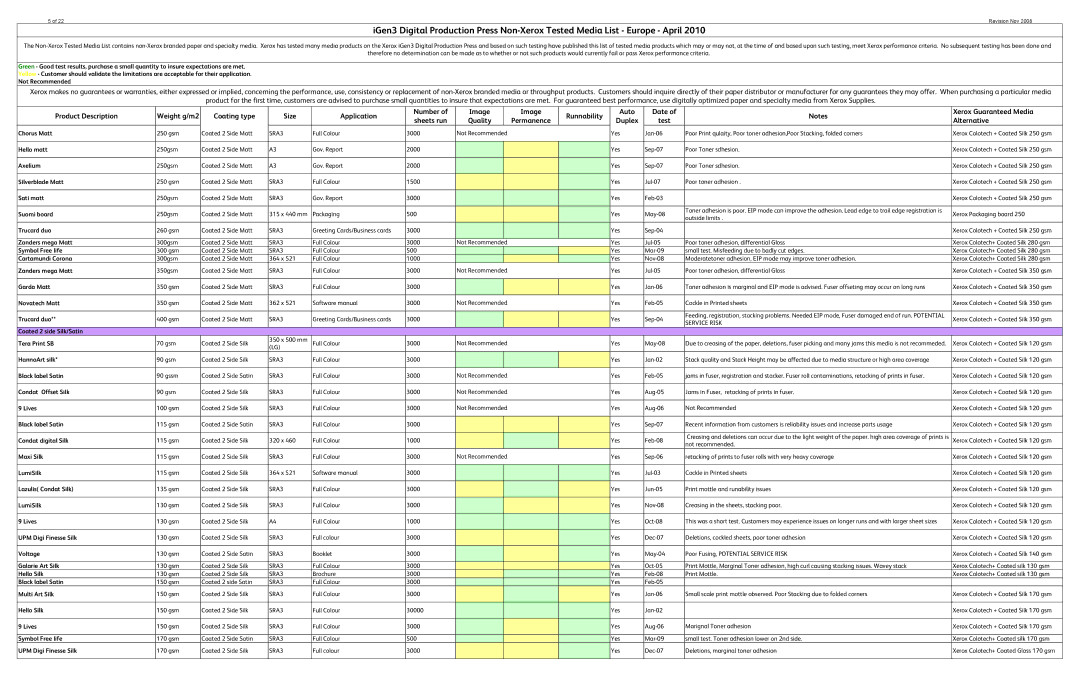

Product Description | Weight g/m2 | Coating type | Size | Application | Number of | Image | | Image | Runnability | Auto | Date of | Notes | Xerox Guaranteed Media |

sheets run | Quality | | Permanence | Duplex | test | Alternative |

| | | | | | | |

Chorus Matt | 250 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Jan-06 | Poor Print qulaity, Poor toner adhesion,Poor Stacking, folded corners | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Hello matt | 250gsm | Coated 2 Side Matt | A3 | Gov. Report | 2000 | | | | | Yes | Sep-07 | Poor Toner sdhesion. | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Axelium | 250gsm | Coated 2 Side Matt | A3 | Gov. Report | 2000 | | | | | Yes | Sep-07 | Poor Toner sdhesion. | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Silverblade Matt | 250 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 1500 | | | | | Yes | Jul-07 | Poor toner adhesion . | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Sati matt | 250gsm | Coated 2 Side Matt | SRA3 | Gov. Report | 3000 | | | | | Yes | Feb-03 | | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Suomi board | 250gsm | Coated 2 Side Matt | 315 x 440 mm | Packaging | 500 | | | | | Yes | May-08 | Toner adhesion is poor. EIP mode can improve the adhesion. Lead edge to trail edge registration is | Xerox Packaging board 250 |

| | | | outside limits . |

| | | | | | | | | | | | |

Trucard duo | 260 gsm | Coated 2 Side Matt | SRA3 | Greeting Cards/Business cards | 3000 | | | | | Yes | Sep-04 | | Xerox Colotech + Coated Silk 250 gsm |

| | | | | | | | | | | | | |

Zanders mega Matt | 300gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | | Yes | Jul-05 | Poor toner adhesion, differential Gloss | Xerox Colotech+ Coated Silk 280 gsm |

Symbol Free life | 300 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 500 | | | | | Yes | Mar-09 | small test. Misfeeding due to badly cut edges. | Xerox Colotech+ Coated Silk 280 gsm |

Cartamundi Corona | 300gsm | Coated 2 Side Matt | 364 x 521 | Full Colour | 1000 | | | | | Yes | Nov-08 | Moderatetoner adhesion, EIP mode may improve toner adhesion. | Xerox Colotech+ Coated Silk 280 gsm |

Zanders mega Matt | 350gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Jul-05 | Poor toner adhesion, differential Gloss | Xerox Colotech + Coated Silk 350 gsm |

| | | | | | | | | | | | | |

Garda Matt | 350 gsm | Coated 2 Side Matt | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-06 | Toner adhesion is marginal and EIP mode is advised. Fuser offseting may occur on long runs | Xerox Colotech + Coated Silk 350 gsm |

| | | | | | | | | | | | | |

Novatech Matt | 350 gsm | Coated 2 Side Matt | 362 x 521 | Software manual | 3000 | Not Recommended | | | Yes | Feb-05 | Cockle in Printed sheets | Xerox Colotech + Coated Silk 350 gsm |

| | | | | | | | | | | | | |

Trucard duo** | 400 gsm | Coated 2 Side Matt | SRA3 | Greeting Cards/Business cards | 3000 | | | | | Yes | Sep-04 | Feeding, registration, stacking problems. Needed EIP mode, Fuser damaged end of run. POTENTIAL | Xerox Colotech + Coated Silk 350 gsm |

| | | | SERVICE RISK |

| | | | | | | | | | | | |

Coated 2 side Silk/Satin | | | | | | | | | | | | | |

Tera Print SB | 70 gsm | Coated 2 Side Silk | 350 x 500 mm | Full Colour | 3000 | Not Recommended | | | Yes | May-08 | Due to creasing of the paper, deletions, fuser picking and many jams this media is not recommeded. | Xerox Colotech + Coated Silk 120 gsm |

| | | (LG) | | | | | | | | | | |

HannoArt silk* | 90 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-02 | Stack quality and Stack Height may be affected due to media structure or high area coverage | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Black label Satin | 90 gssm | Coated 2 Side Satin | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Feb-05 | jams in fuser, registration and stacker. Fuser roll contaminations, retacking of prints in fuser. | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | |

Condat Offset Silk | 90 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Aug-05 | Jams in Fuser, retacking of prints in fuser. | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | |

9 Lives | 100 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Aug-06 | Not Recommended | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Black label Satin | 115 gsm | Coated 2 Side Satin | SRA3 | Full Colour | 3000 | | | | | Yes | Sep-07 | Recent information from customers is reliability issues and increase parts usage | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Condat digital Silk | 115 gsm | Coated 2 Side Silk | 320 x 460 | Full Colour | 1000 | | | | | Yes | Feb-08 | Creasing and deletions can occur due to the light weight of the paper. high area coverage of prints is | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | not recommended. | |

Maxi Silk | 115 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | Not Recommended | | | Yes | Sep-06 | retacking of prints to fuser rolls with very heavy coverage | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

LumiSilk | 115 gsm | Coated 2 Side Silk | 364 x 521 | Software manual | 3000 | | | | | Yes | Jul-03 | Cockle in Printed sheets | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Lazulis( Condat Silk) | 135 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Jun-05 | Print mottle and runability issues | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

LumiSilk | 130 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Nov-08 | Creasing in the sheets, stacking poor. | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

9 Lives | 130 gsm | Coated 2 Side Silk | A4 | Full Colour | 1000 | | | | | Yes | Oct-08 | This was a short test. Customers may experience issues on longer runs and with larger sheet sizes | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

UPM Digi Finesse Silk | 130 gsm | Coated 2 Side Silk | SRA3 | Full colour | 3000 | | | | | Yes | Dec-07 | Deletions, cockled sheets, poor toner adhesion | Xerox Colotech + Coated Silk 120 gsm |

| | | | | | | | | | | | | |

Voltage | 130 gsm | Coated 2 Side Satin | SRA3 | Booklet | 3000 | | | | | Yes | May-04 | Poor Fusing, POTENTIAL SERVICE RISK | Xerox Colotech + Coated Silk 140 gsm |

| | | | | | | | | | | | | |

Galarie Art Silk | 130 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Oct-05 | Print Mottle, Marginal Toner adhesion, high curl causing stacking issues. Wavey stack | Xerox Colotech+ Coated silk 130 gsm |

Hello Silk | 130 gsm | Coated 2 Side Silk | SRA3 | Brochure | 3000 | | | | | Yes | Feb-08 | Print Mottle. | Xerox Colotech+ Coated silk 130 gsm |

Black label Satin | 150 gsm | Coated 2 side Satin | SRA3 | Full Colour | 3000 | | | | | Yes | Feb-05 | | |

Multi Art Silk | 150 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Jan-06 | Small scale print mottle observed. Poor Stacking due to folded corners | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Hello Silk | 150 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 30000 | | | | | Yes | Jan-02 | | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

9 Lives | 150 gsm | Coated 2 Side Silk | SRA3 | Full Colour | 3000 | | | | | Yes | Aug-06 | Marignal Toner adhesion | Xerox Colotech + Coated Silk 170 gsm |

| | | | | | | | | | | | | |

Symbol Free life | 170 gsm | Coated 2 Side Satin | SRA3 | Full Colour | 500 | | | | | Yes | Mar-09 | small test. Toner adhesion lower on 2nd side. | Xerox Colotech+ Coated silk 170 gsm |

UPM Digi Finesse Silk | 170 gsm | Coated 2 Side Silk | SRA3 | Full colour | 3000 | | | | | Yes | Dec-07 | Deletions, marginal toner adhesion | Xerox Colotech+ Coated Gloss 170 gsm |

| | | | | | | | | | | | | |