Battery Failures

Some common causes for battery failure are: incorrect initial activation, lack of water, adding chemicals other than water after initial activation, undercharging, overcharging, corroded connections, freezing. These failures do not constitute warranty.

Lubrication

WARNING: Always stop engine and disconnect spark plug wire before cleaning, lubricating or doing any kind of work on lawn tractor.

Pivot Points

•Lubricate all pivot points with light oil once a season.

Ball Joints

•The ball joints and drag link ends are permanently lubricated and do not need periodic lubrication.

Hydrostatic Transmission

The hydrostatic transmission is filled at the factory and does not require checking. If repairs are needed, contact your local service dealer. (Hydrostatic transmission contains approximately 2.5 quarts of SAE 20W50 oil.)

Lube

Lube

Lube

Figure 17

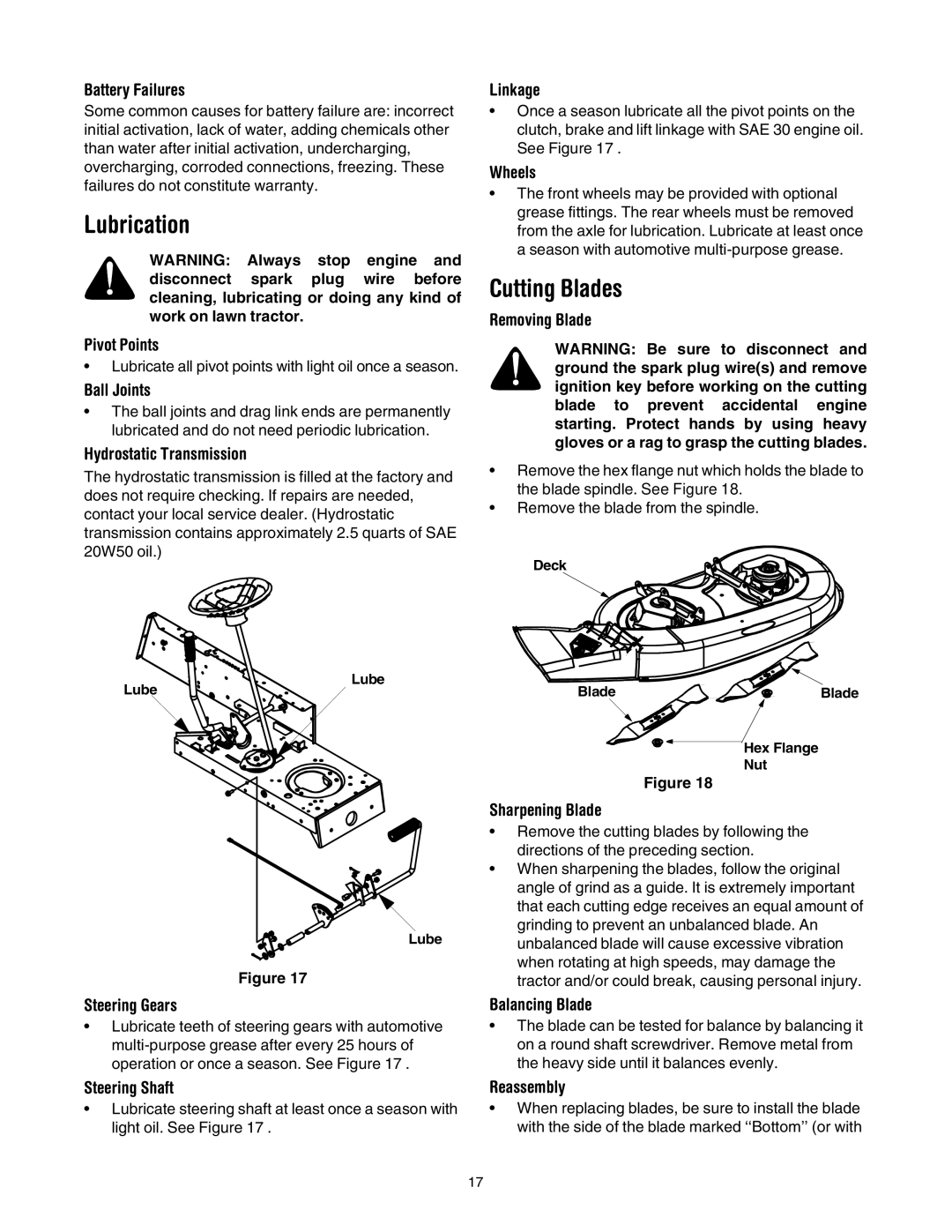

Steering Gears

•Lubricate teeth of steering gears with automotive

Steering Shaft

•Lubricate steering shaft at least once a season with light oil. See Figure 17 .

Linkage

•Once a season lubricate all the pivot points on the clutch, brake and lift linkage with SAE 30 engine oil. See Figure 17 .

Wheels

•The front wheels may be provided with optional grease fittings. The rear wheels must be removed from the axle for lubrication. Lubricate at least once a season with automotive

Cutting Blades

Removing Blade

WARNING: Be sure to disconnect and ground the spark plug wire(s) and remove ignition key before working on the cutting blade to prevent accidental engine starting. Protect hands by using heavy gloves or a rag to grasp the cutting blades.

•Remove the hex flange nut which holds the blade to the blade spindle. See Figure 18.

•Remove the blade from the spindle.

Deck

Blade | Blade |

Hex Flange

Nut

Figure 18

Sharpening Blade

•Remove the cutting blades by following the directions of the preceding section.

•When sharpening the blades, follow the original angle of grind as a guide. It is extremely important that each cutting edge receives an equal amount of grinding to prevent an unbalanced blade. An unbalanced blade will cause excessive vibration when rotating at high speeds, may damage the tractor and/or could break, causing personal injury.

Balancing Blade

•The blade can be tested for balance by balancing it on a round shaft screwdriver. Remove metal from the heavy side until it balances evenly.

Reassembly

•When replacing blades, be sure to install the blade with the side of the blade marked ‘‘Bottom’’ (or with

17