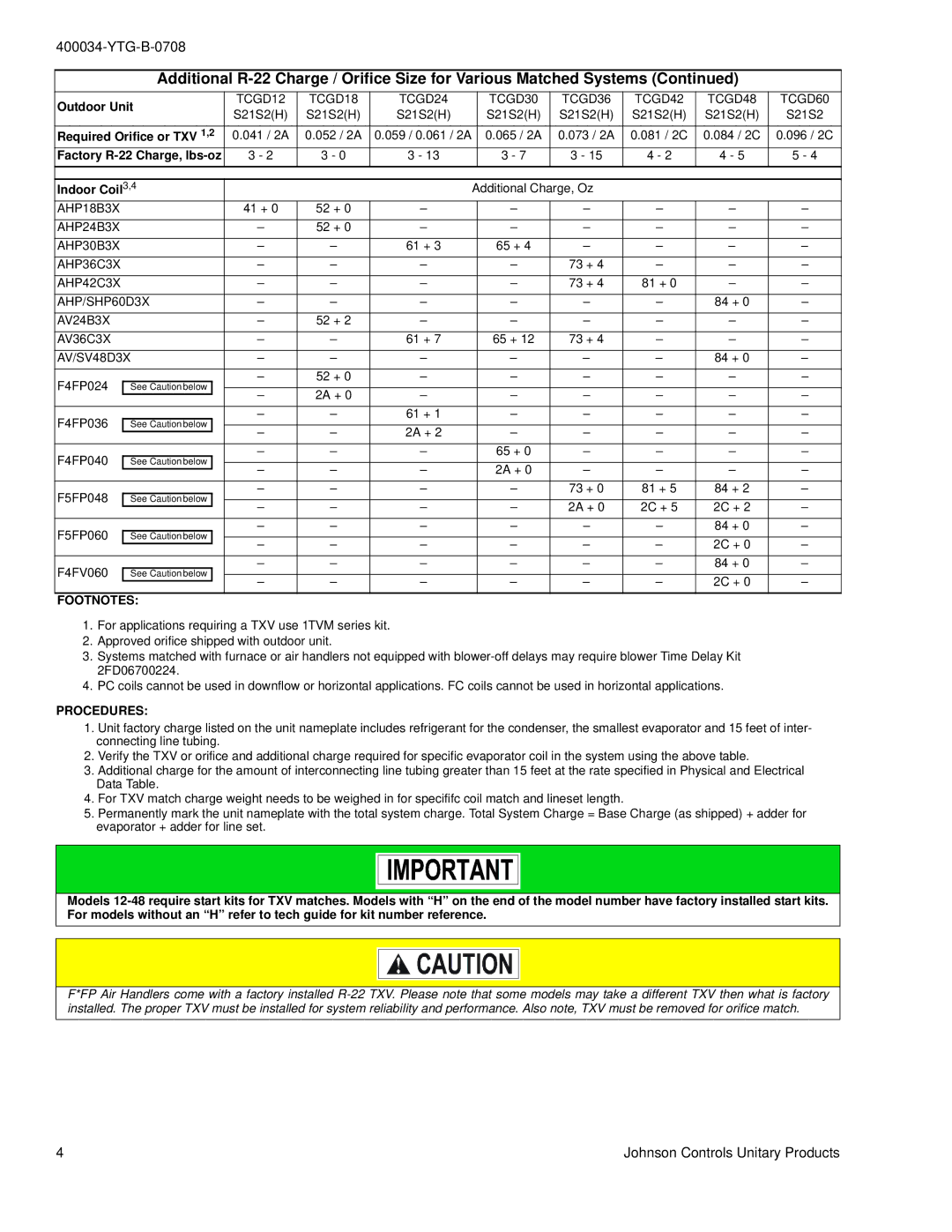

TCGD12 THRU 60 specifications

The York TCGD12 THRU 60 is a highly efficient and versatile unit designed for commercial and industrial applications. This series of air-cooled chiller and heat pump systems is renowned for its reliability and advanced technologies, making it a popular choice among HVAC professionals.One of the main features of the TCGD12 THRU 60 is its impressive energy efficiency. The unit employs a sophisticated design that significantly reduces energy consumption while maintaining optimal performance. The incorporation of variable speed compressors allows the system to adjust its cooling capacity according to the actual load, resulting in lower operating costs and enhanced energy savings.

Another notable characteristic is its use of environmentally friendly refrigerants. This series adheres to the latest industry standards, utilizing refrigerants that minimize environmental impact. This commitment to sustainability ensures that users can operate their systems with a reduced carbon footprint, aligning with modern regulations and corporate responsibility goals.

The TCGD12 THRU 60 also features a robust control system that simplifies operation and enhances performance monitoring. Advanced controls enable users to set customized operating parameters and schedule maintenance, improving the unit's longevity and reliability. With an intuitive interface, operators can easily manage system settings to optimize comfort and efficiency.

In terms of construction, the TCGD12 THRU 60 is built with durable materials designed to withstand harsh operating conditions. The exterior casing is weather-resistant, ensuring that the unit can perform reliably in varying climates. Additionally, the system's design promotes ease of installation and maintenance, reducing downtime and service costs.

Noise reduction is yet another defining feature of this series. The TCGD12 THRU 60 incorporates advanced sound-dampening technologies, allowing for quieter operation, making it suitable for sound-sensitive environments like schools, hospitals, and office buildings.

Lastly, the unit's versatility is paramount. With options for air or water-cooled systems, the TCGD12 can be tailored to fit different applications and installation requirements. Whether for cooling, heating, or both, this unit provides a comprehensive solution for modern HVAC needs. Overall, the York TCGD12 THRU 60 stands out for its efficiency, advanced technology, and robust design, representing a significant step forward in the field of commercial heating and cooling solutions.