Disassembly continued

plate and set aside in a safe place to pre- vent damage. At this point, make certain to note the orientation of the groove on the rear of each bearing with respect to the inlet port. They MUST be reassembled in the same way as disassembled; that is, they must point toward the inlet port, or severe pump damage may result when the pump is started.

WARNING: (Read before steps 7 & 8) Extreme caution must be exercised when removing the gear shafts and bearing. For the 40 cc/rev and above capacity pumps, which have two (2) tapped holes in the D- bearing faces, an optional disassembly method is possible. If the gear shaft and two

For 20 cc/rev and smaller capa- cities, there are no tapped holes in the

7)Slide the gear shafts and bearings out of the center plate. They will not come out separately as the gear teeth will not clear the bearings. Take extreme care not to nick or ding the gear teeth or the edges of the bearings. If they will not slide out easily, use a hammer with a plastic or soft brass head to gently tap them out. DO NOT use a

8)Slide the bearings from the shafts, again taking extreme care not to damage the gear teeth, bearing edges or the shafts. If the bearings will not slide easily from the shaft (due to residual polymer), use a plastic or soft

9)On the 3 cc/rev and smaller, slide the gears from their shafts and remove the keys from the shaft.

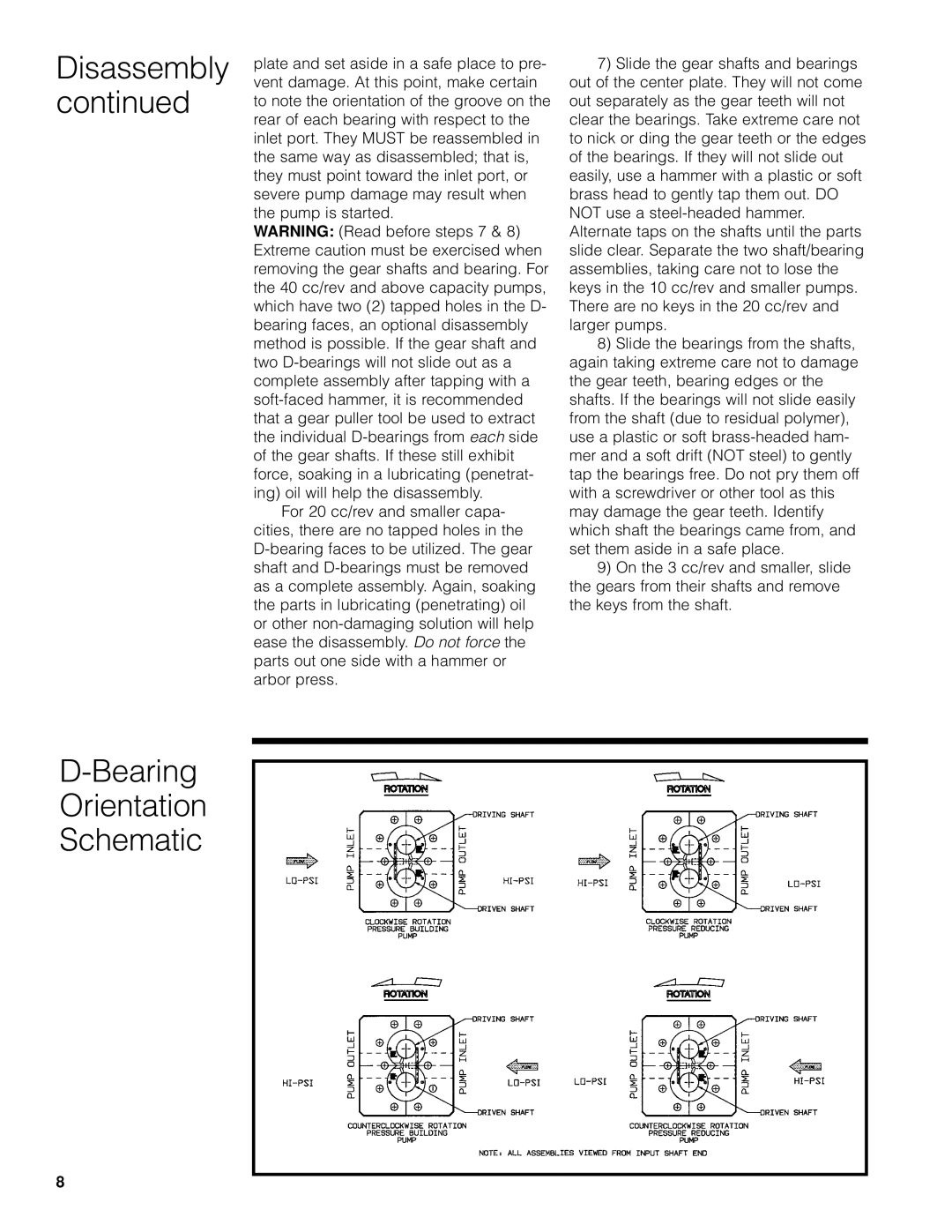

D-Bearing

Orientation

Schematic

8