Fuel

F6

![]()

![]() WARNING

WARNING

•Keep open flames away from the area where fuel is handled or stored.

•Mix and store fuel only in an approved gasoline container.

Mix a regular grade gasoline (leaded or unleaded,

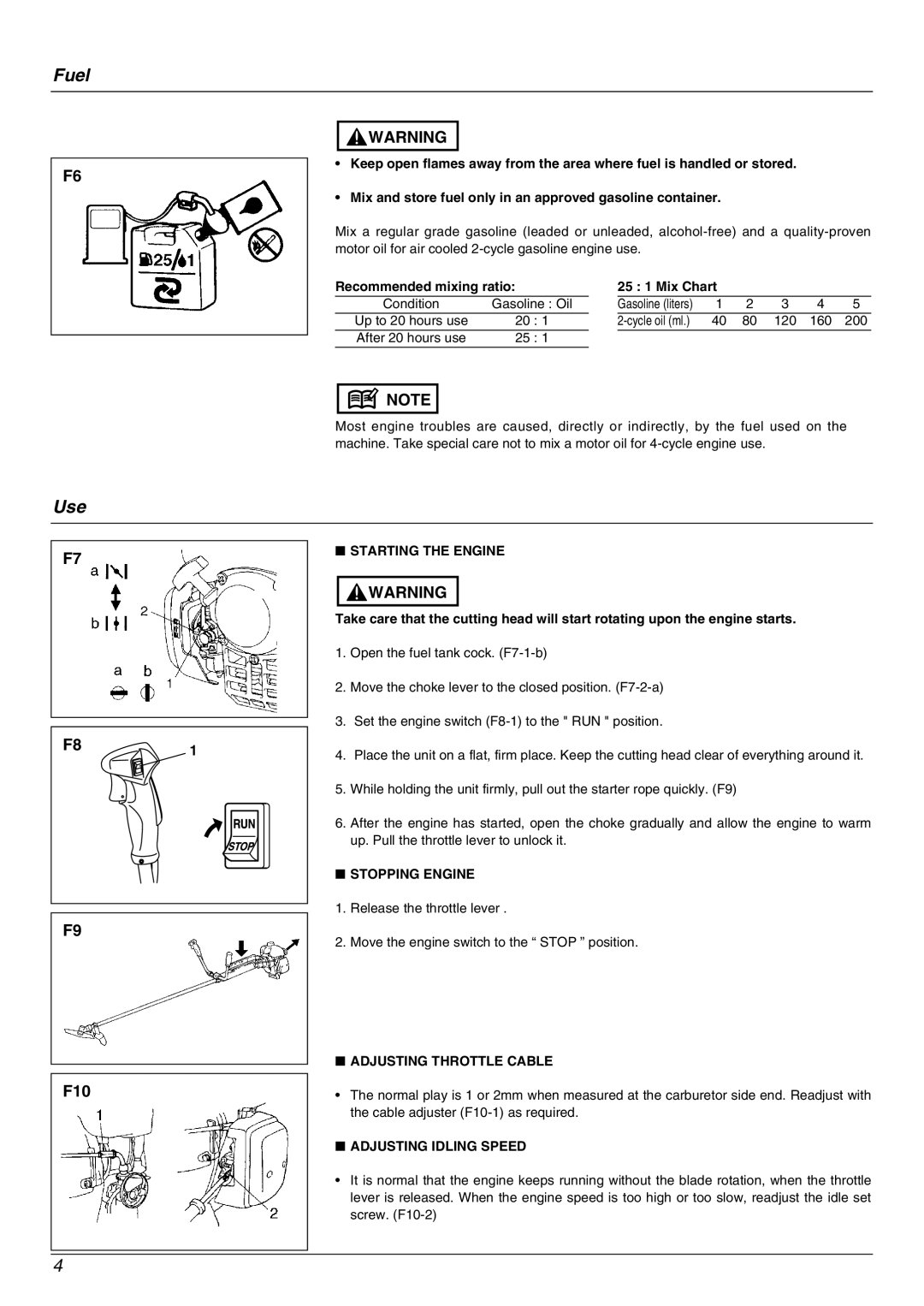

Recommended mixing ratio: | 25 : 1 Mix Chart |

|

|

|

| |||

Condition | Gasoline : Oil |

| Gasoline (liters) | 1 | 2 | 3 | 4 | 5 |

Up to 20 hours use | 20 : 1 |

| 40 | 80 | 120 | 160 | 200 | |

After 20 hours use | 25 : 1 |

|

|

|

|

|

|

|

![]()

![]() NOTE

NOTE

Most engine troubles are caused, directly or indirectly, by the fuel used on the machine. Take special care not to mix a motor oil for

Use

F7

F81

F9

F10

■STARTING THE ENGINE

![]()

![]() WARNING

WARNING

Take care that the cutting head will start rotating upon the engine starts.

1.Open the fuel tank cock.

2.Move the choke lever to the closed position.

3.Set the engine switch

4.Place the unit on a flat, firm place. Keep the cutting head clear of everything around it.

5.While holding the unit firmly, pull out the starter rope quickly. (F9)

6.After the engine has started, open the choke gradually and allow the engine to warm up. Pull the throttle lever to unlock it.

■STOPPING ENGINE

1.Release the throttle lever .

2.Move the engine switch to the “ STOP ” position.

■ADJUSTING THROTTLE CABLE

•The normal play is 1 or 2mm when measured at the carburetor side end. Readjust with the cable adjuster

■ADJUSTING IDLING SPEED

•It is normal that the engine keeps running without the blade rotation, when the throttle lever is released. When the engine speed is too high or too slow, readjust the idle set screw.

4