Maintenance

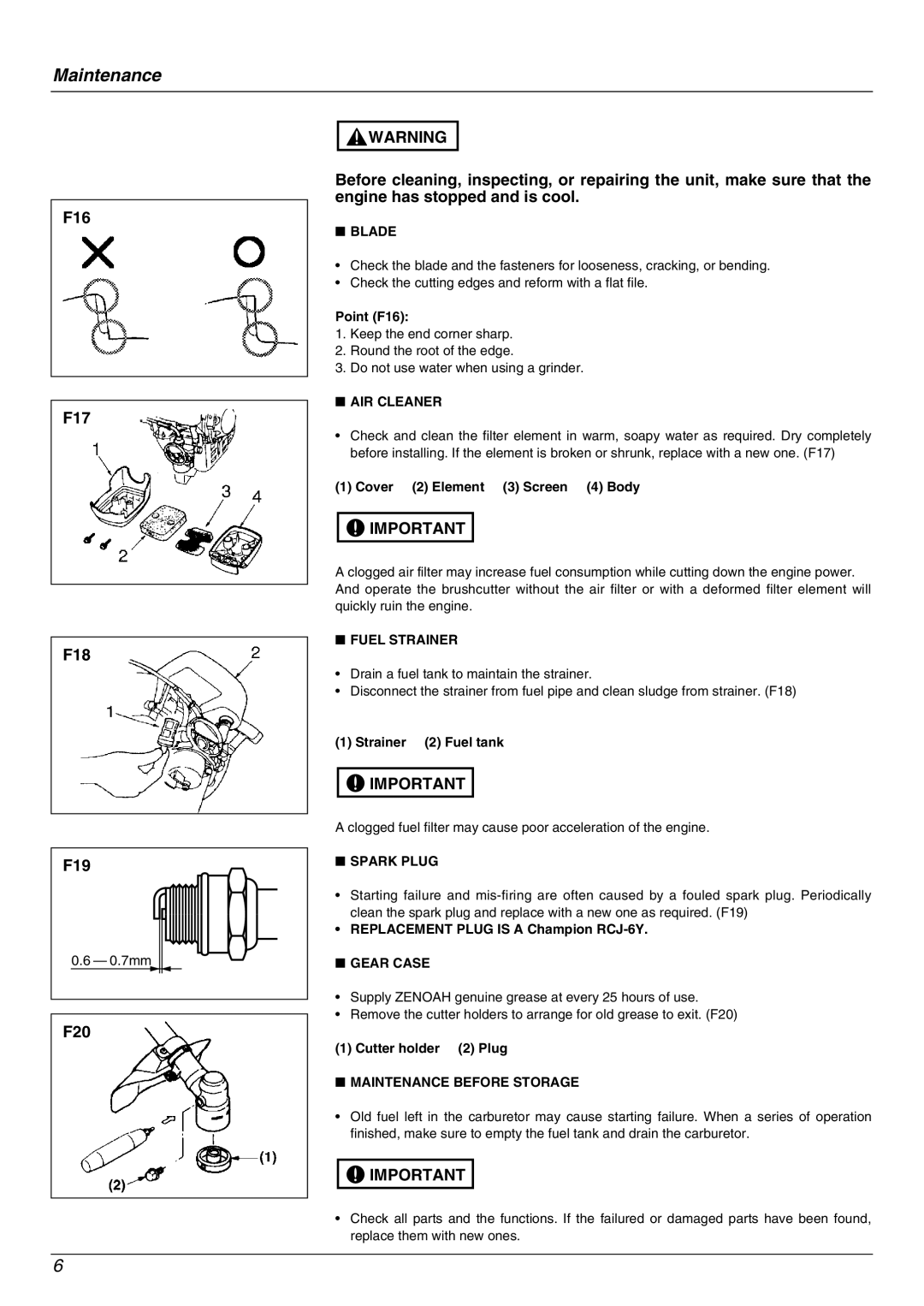

F16

F17

F18

F19

0.6 — 0.7mm

F20

![]()

![]() WARNING

WARNING

Before cleaning, inspecting, or repairing the unit, make sure that the engine has stopped and is cool.

■BLADE

•Check the blade and the fasteners for looseness, cracking, or bending.

•Check the cutting edges and reform with a flat file.

Point (F16):

1.Keep the end corner sharp.

2.Round the root of the edge.

3.Do not use water when using a grinder.

■AIR CLEANER

•Check and clean the filter element in warm, soapy water as required. Dry completely before installing. If the element is broken or shrunk, replace with a new one. (F17)

(1) Cover (2) Element (3) Screen (4) Body

![]()

![]() IMPORTANT

IMPORTANT

A clogged air filter may increase fuel consumption while cutting down the engine power. And operate the brushcutter without the air filter or with a deformed filter element will quickly ruin the engine.

■FUEL STRAINER

•Drain a fuel tank to maintain the strainer.

•Disconnect the strainer from fuel pipe and clean sludge from strainer. (F18)

(1) Strainer (2) Fuel tank

![]()

![]() IMPORTANT

IMPORTANT

A clogged fuel filter may cause poor acceleration of the engine.

■SPARK PLUG

•Starting failure and

•REPLACEMENT PLUG IS A Champion

■GEAR CASE

•Supply ZENOAH genuine grease at every 25 hours of use.

•Remove the cutter holders to arrange for old grease to exit. (F20)

(1) Cutter holder (2) Plug

■MAINTENANCE BEFORE STORAGE

•Old fuel left in the carburetor may cause starting failure. When a series of operation finished, make sure to empty the fuel tank and drain the carburetor.

![]()

![]() IMPORTANT

IMPORTANT

•Check all parts and the functions. If the failured or damaged parts have been found, replace them with new ones.

6