Section 8 | R |

| |

|

|

|

|

|

| STEERING COMPONENTS |

|

|

|

|

|

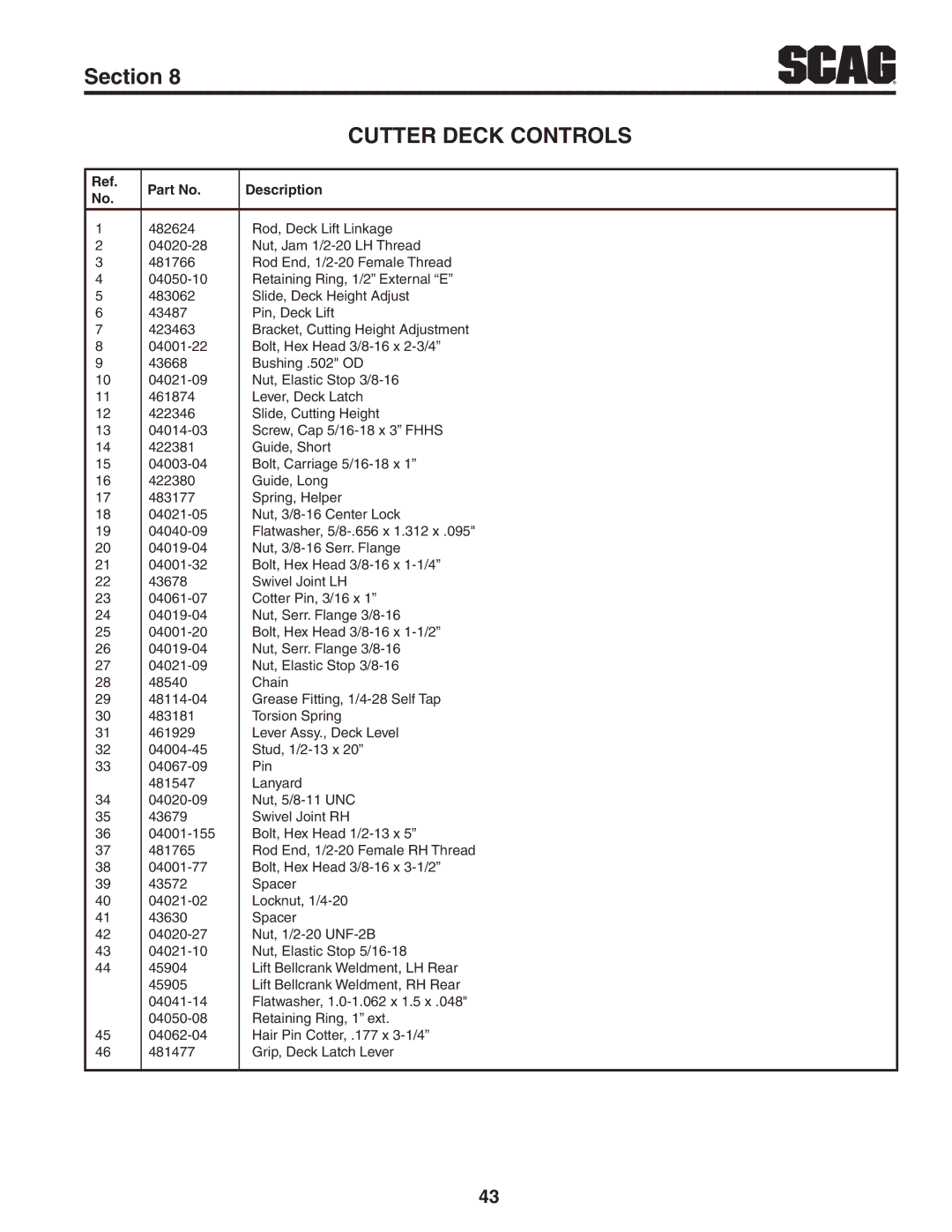

Ref. | Part No. | Description |

|

No. |

| ||

|

|

| |

1 | 482340 | Grip, Control Lever |

|

2 | 461386 | Handle Bar (Includes item 1) |

|

3

4

5

6

7

8 | 422372 | Bar, Control Lever |

9 | Nut, Elastic Stop | |

10 | 482330 | Rod End, |

11 | Nut, | |

12 | 482623 | Rod, Pump Control Linkage |

13 | Nut, | |

14 | 482331 | Rod End, |

15 | 43477 | Pin Retainer |

16

17

18 | 43602 | Spacer, Pump Dampener |

19 | 423599 | Plate, Control Lever |

20 | Bolt, Hex Head | |

21 | *482452 | Gas Damper |

| *482794 | Gas Damper |

22 | Bolt, Hex Head | |

23 | 482099 | Block, Clamping |

24 | Bolt, Carriage, | |

25 | 461770 | Control Plate - LH (Includes Decal) |

| 461771 | Control Plate - RH (Includes Decal) |

26

27

28

29 | 43616 | Shaft, Steering Control |

30

31

32 | 43559 | Spacer, Control |

33 | 49574 | Control Lever Assy RH (Includes 31 & 35) |

| 49573 | Control Lever Assy LH (Includes 31 & 35) |

34 | Nut, Elastic Stop | |

35 | Bushing |

36

37

38 | 423057 | Bracket, Switch Actuator |

39 | Bolt, Hex Serr. Flange | |

40 | Bolt, Carr. | |

41 | 45918 | Bracket, Control Return |

42 | 481389 | Spring |

43 | 43477 | Pin Retainer |

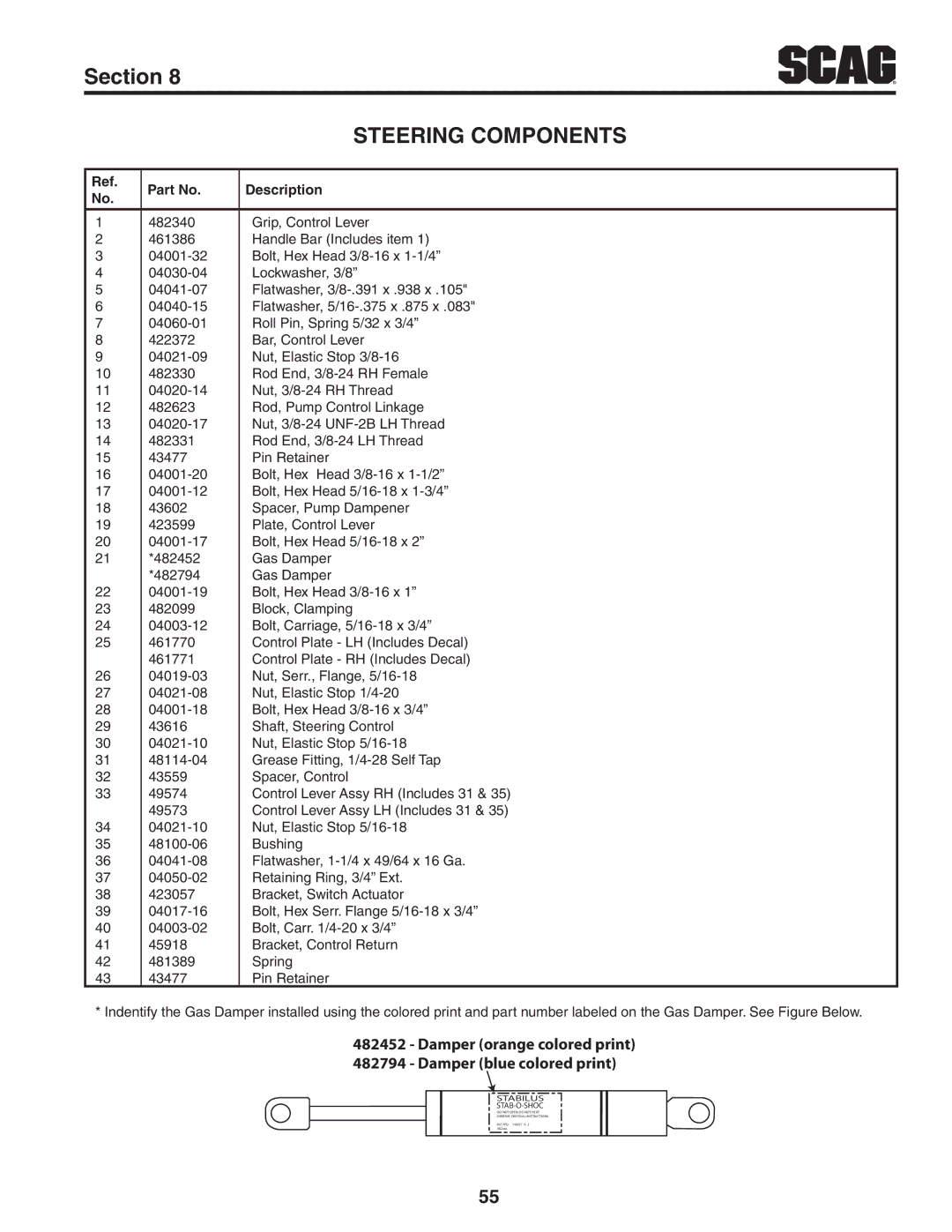

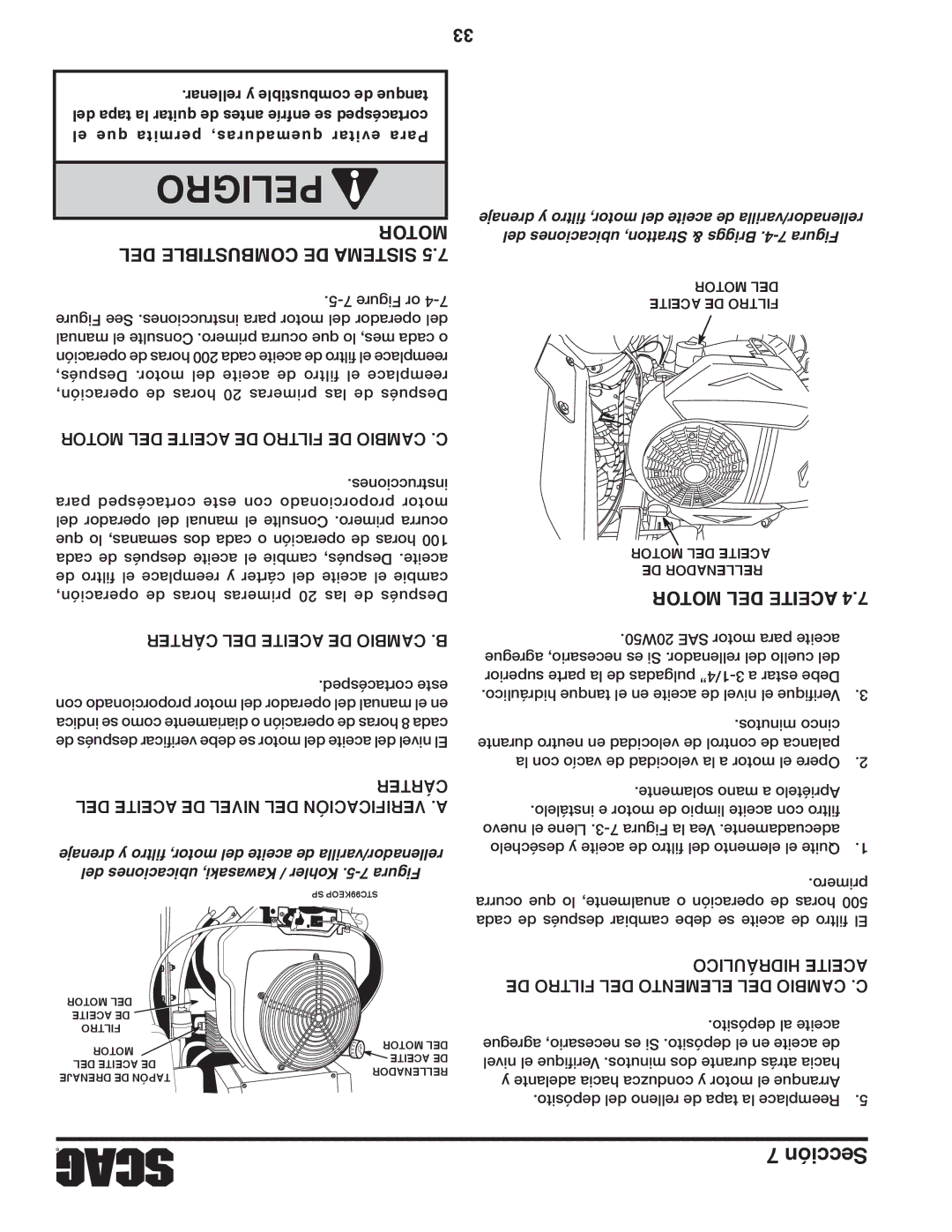

* Indentify the Gas Damper installed using the colored print and part number labeled on the Gas Damper. See Figure Below.

482452 - Damper (orange colored print)

482794 - Damper (blue colored print)

STABILUS

DO NOT OPEN. DO NOT HEAT

OBSERVE DISPOSAL INSTRUCTIONS

8517PQ 194/07 A 2 482xxx

55