INSTALLATION | ||

|

|

|

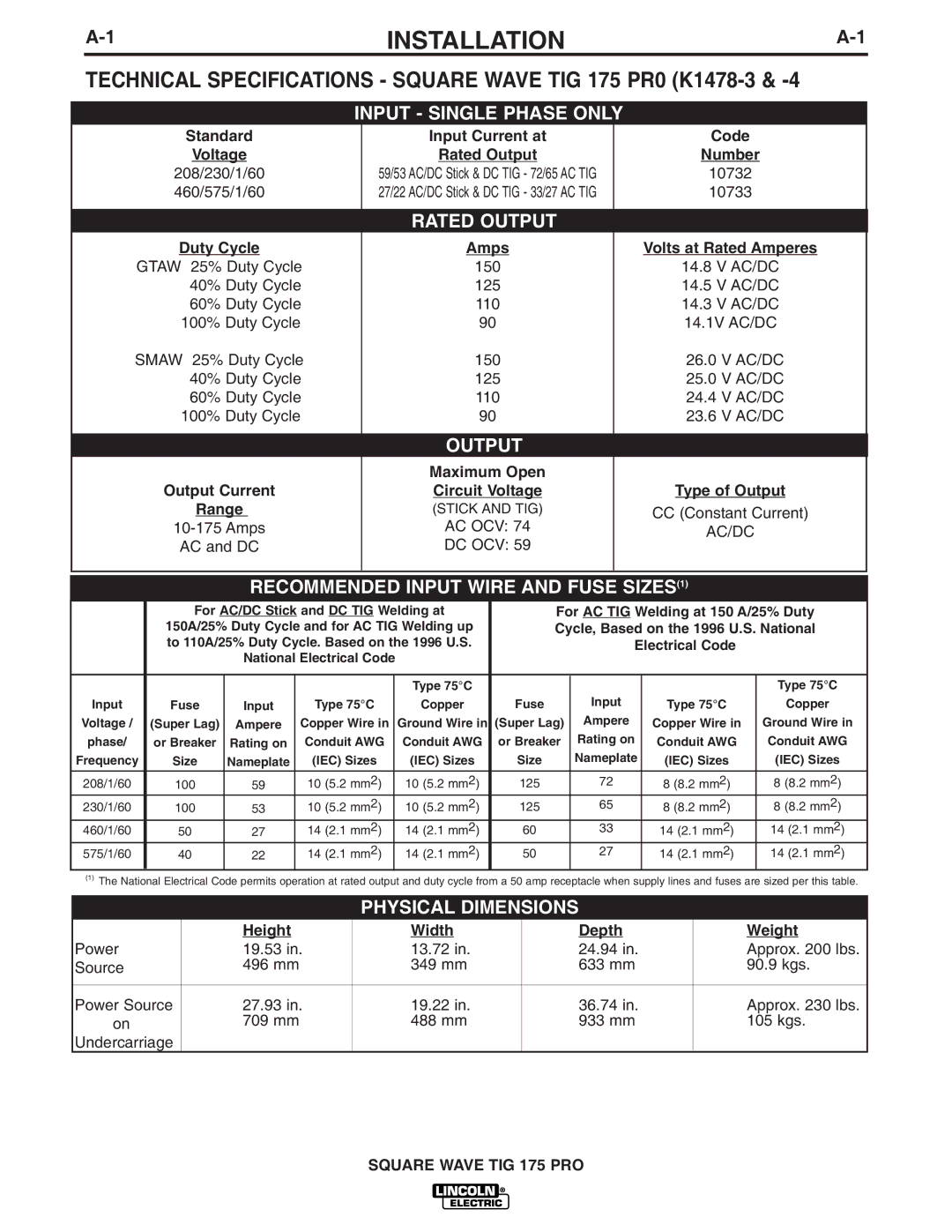

TECHNICAL SPECIFICATIONS - SQUARE WAVE TIG 175 PR0 (K1478-3 & -4

INPUT - SINGLE PHASE ONLY

Standard

Voltage

208/230/1/60

460/575/1/60

Duty Cycle

GTAW 25% Duty Cycle

40% Duty Cycle

60% Duty Cycle

100% Duty Cycle

SMAW 25% Duty Cycle

40% Duty Cycle

60% Duty Cycle

100% Duty Cycle

Output Current

Range

AC and DC

Input Current at

Rated Output

59/53 AC/DC Stick & DC TIG - 72/65 AC TIG 27/22 AC/DC Stick & DC TIG - 33/27 AC TIG

RATED OUTPUT

Amps

150

125

110

90

150

125

110

90

OUTPUT

Maximum Open

Circuit Voltage

(STICK AND TIG)

AC OCV: 74

DC OCV: 59

Code

Number

10732

10733

Volts at Rated Amperes

14.8V AC/DC

14.5V AC/DC

14.3V AC/DC 14.1V AC/DC

26.0V AC/DC

25.0V AC/DC

24.4V AC/DC

23.6V AC/DC

Type of Output

CC(Constant Current) AC/DC

RECOMMENDED INPUT WIRE AND FUSE SIZES(1)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| For AC/DC Stick and DC TIG Welding at |

|

| For AC TIG Welding at 150 A/25% Duty |

|

| ||||||||||||||

|

|

|

|

| 150A/25% Duty Cycle and for AC TIG Welding up |

|

| Cycle, Based on the 1996 U.S. National |

|

| ||||||||||||||

|

|

|

|

| to 110A/25% Duty Cycle. Based on the 1996 U.S. |

|

|

| Electrical Code |

|

|

| ||||||||||||

|

|

|

|

|

|

| National Electrical Code |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Type 75°C |

|

| Input |

|

|

|

| Type 75°C |

| ||

| Input |

|

|

| Fuse |

| Input |

|

| Type 75°C |

|

| Copper | Fuse |

| Type 75°C |

|

| Copper |

| ||||

| Voltage / |

|

| (Super Lag) |

| Ampere |

|

| Copper Wire in |

|

| Ground Wire in | (Super Lag) | Ampere |

| Copper Wire in |

|

| Ground Wire in |

| ||||

| phase/ |

|

| or Breaker |

| Rating on |

|

| Conduit AWG |

|

| Conduit AWG | or Breaker | Rating on |

| Conduit AWG |

|

| Conduit AWG |

| ||||

| Frequency |

|

|

| Size |

| Nameplate |

|

| (IEC) Sizes |

|

| (IEC) Sizes | Size | Nameplate |

| (IEC) Sizes |

|

| (IEC) Sizes |

| |||

| 208/1/60 |

|

| 100 |

| 59 |

|

| 10 (5.2 mm2) |

|

| 10 (5.2 mm2) | 125 | 72 |

| 8 (8.2 mm2) |

|

| 8 (8.2 mm2) |

| ||||

| 230/1/60 |

|

| 100 |

| 53 |

|

| 10 (5.2 mm2) |

|

| 10 (5.2 mm2) | 125 | 65 |

| 8 (8.2 mm2) |

|

| 8 (8.2 mm2) |

| ||||

| 460/1/60 |

|

| 50 |

| 27 |

|

| 14 (2.1 mm2) |

|

| 14 (2.1 mm2) | 60 |

| 33 |

| 14 (2.1 mm2) |

|

| 14 (2.1 mm2) |

| |||

| 575/1/60 |

|

| 40 |

| 22 |

|

| 14 (2.1 mm2) |

|

| 14 (2.1 mm2) | 50 |

| 27 |

| 14 (2.1 mm2) |

|

| 14 (2.1 mm2) |

| |||

(1)The National Electrical Code permits operation at rated output and duty cycle from a 50 amp receptacle when supply lines and fuses are sized per this table.

PHYSICAL DIMENSIONS

| Height | Width | Depth | Weight |

Power | 19.53 in. | 13.72 in. | 24.94 in. | Approx. 200 lbs. |

Source | 496 mm | 349 mm | 633 mm | 90.9 kgs. |

|

|

|

|

|

Power Source | 27.93 in. | 19.22 in. | 36.74 in. | Approx. 230 lbs. |

on | 709 mm | 488 mm | 933 mm | 105 kgs. |

Undercarriage |

|

|

|

|