E-1 TROUBLESHOOTINGE-1

HOW TO USE TROUBLESHOOTING GUIDE

![]() WARNING

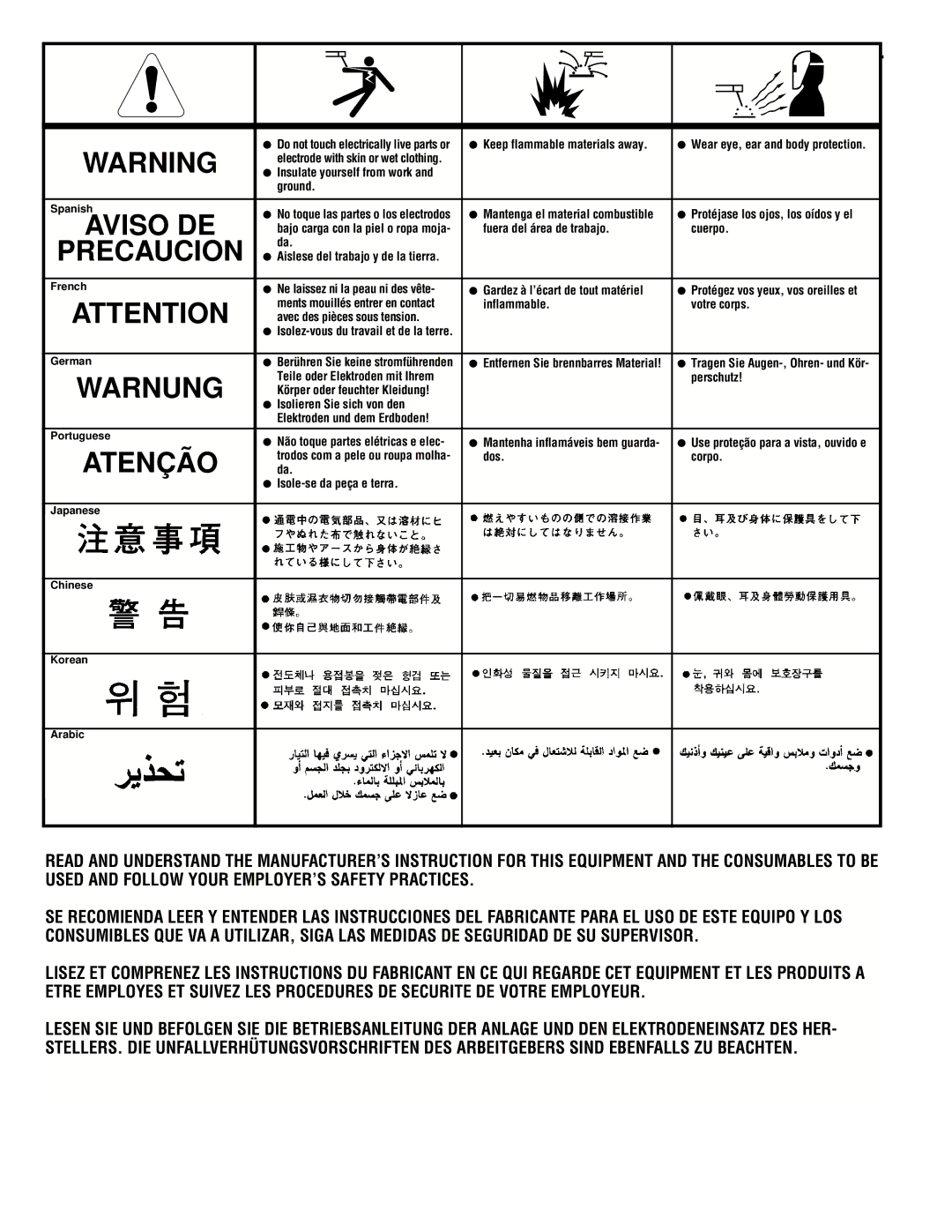

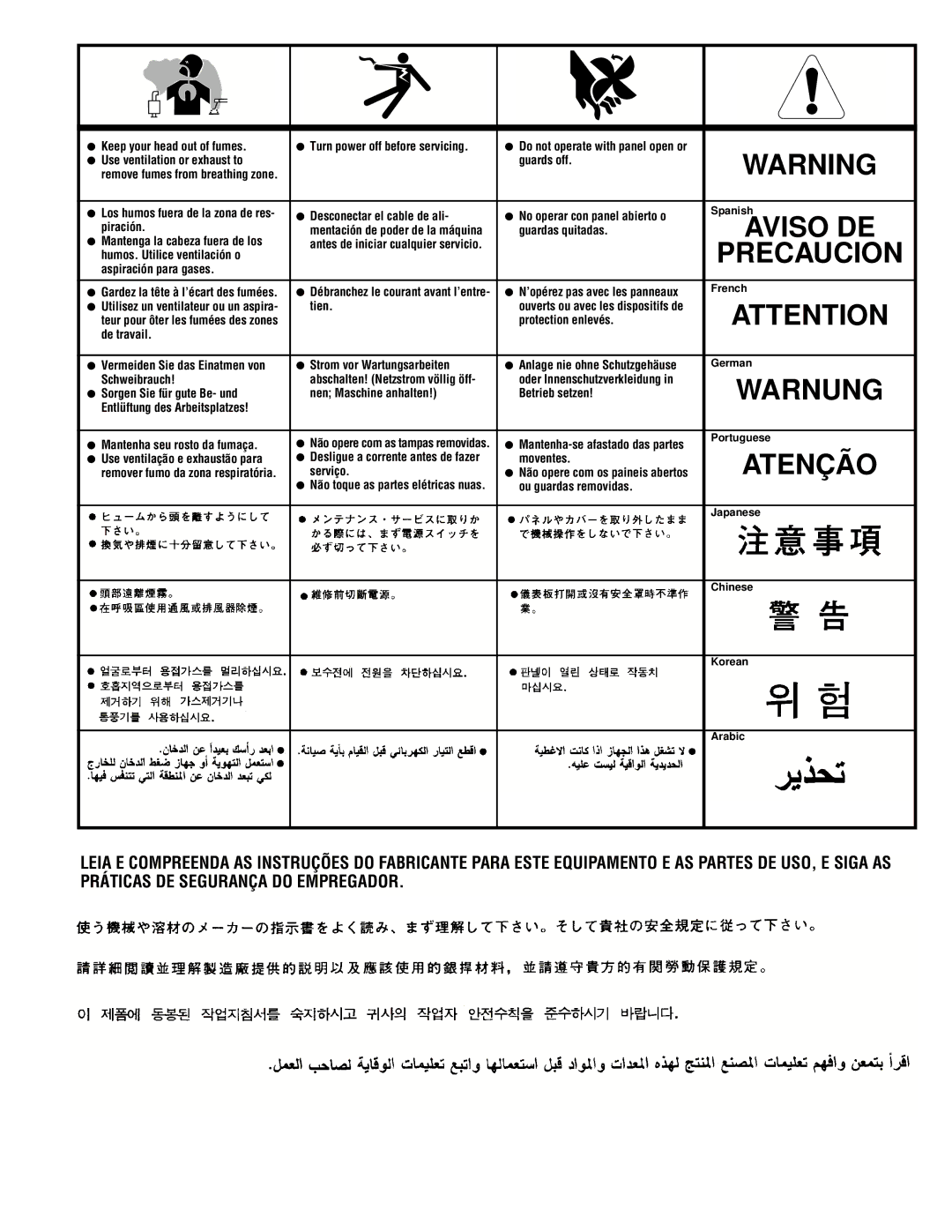

WARNING

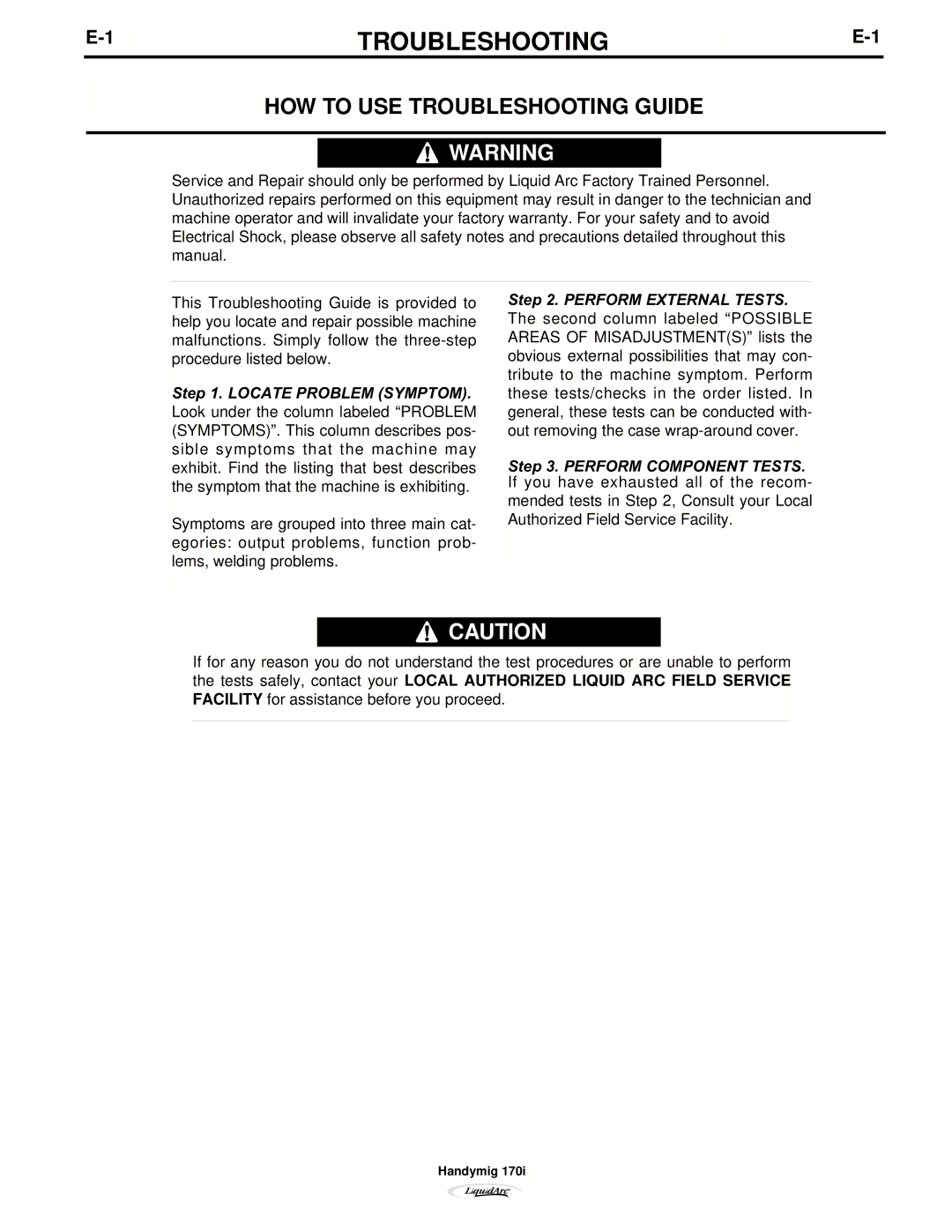

Service and Repair should only be performed by Liquid Arc Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

__________________________________________________________________________

This Troubleshooting Guide is provided to help you locate and repair possible machine malfunctions. Simply follow the

Step 1. LOCATE PROBLEM (SYMPTOM). Look under the column labeled “PROBLEM (SYMPTOMS)”. This column describes pos- sible symptoms that the machine may exhibit. Find the listing that best describes the symptom that the machine is exhibiting.

Symptoms are grouped into three main cat- egories: output problems, function prob- lems, welding problems.

Step 2. PERFORM EXTERNAL TESTS. The second column labeled “POSSIBLE AREAS OF MISADJUSTMENT(S)” lists the obvious external possibilities that may con- tribute to the machine symptom. Perform these tests/checks in the order listed. In general, these tests can be conducted with- out removing the case

Step 3. PERFORM COMPONENT TESTS. If you have exhausted all of the recom-

mended tests in Step 2, Consult your Local Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests safely, contact your LOCAL AUTHORIZED LIQUID ARC FIELD SERVICE

FACILITY for assistance before you proceed.

_____________________________________________________________________

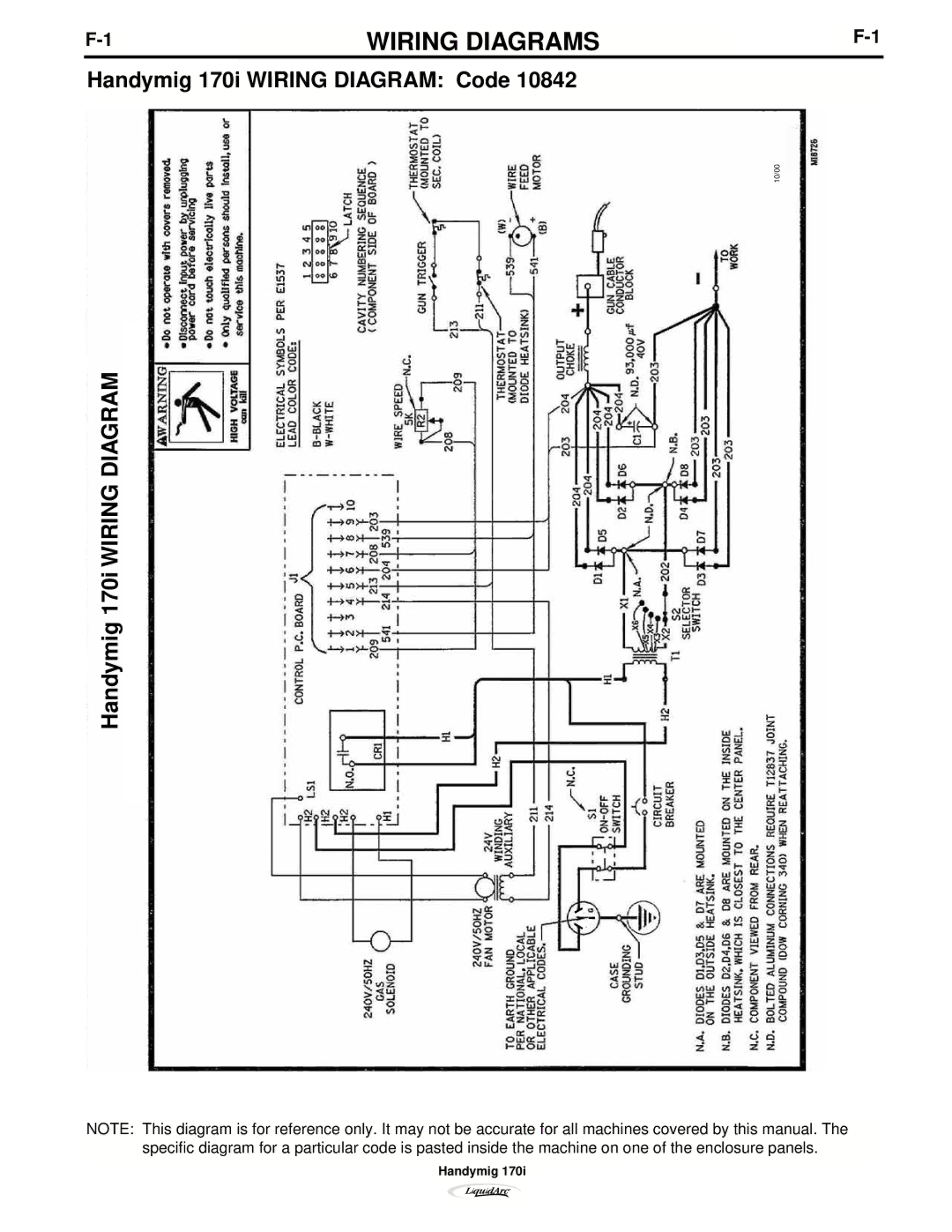

Handymig 170i