Mounting Plain Ended Blades

Included as an accessory are two Plain End Blade Adapters. When installed, they enable the mounting of plain end saw blades (not included). To install blades of this type:

1.Using a Hex Wrench, loosen both set screws on each of the Plain End Blade Adapters.

2.Slide the gap between the two set screws over each end of the blade.

3.Evenly tighten all set screws. Pull on the Adapters slightly to make sure they are secure.

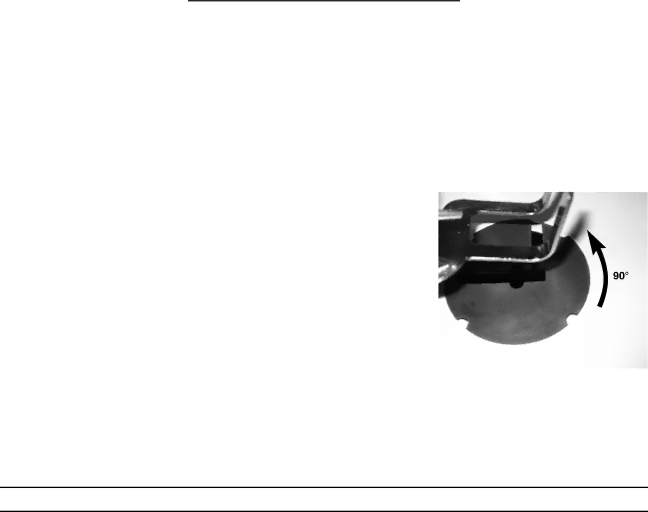

4.Remove the old blade. Pull the Insert out and rotate it 90° to the position shown at right.

5.Loosen the Blade Tension Knob (21) by turning counterclockwise about two full turns.

6.Place the Blade Adapter’s bar under the end of the Lower Blade Holder (40). Make sure that the blade’s teeth point the right direction.

Turn the Insert 90° Counterclock-

wise to this position.

7.Push down slightly on the Upper Rocker Arm (29), and place the Blade Adapter’s other bar over the end of the Upper Blade Holder (37).

8.Tighten the Blade Tension Knob (21) by turning clockwise about two full turns.

TROUBLESHOOTING

PROBLEM | PROBABLE CAUSE | SUGGESTED REMEDY |

|

|

|

|

|

| 1. Wrong blade tension | 1. Adjust blade tension. |

|

| 2. | 2. Reduce feed cut rate. |

|

Blades breaking | 3. Wrong blade application | 3. Use narrow blades for cutting thin |

|

| wood, wide blades for cutting thicker |

| |

|

|

| |

|

| wood. |

|

| 4. Blade twisting in wood | 4. Avoid side pressure on blade. |

|

|

|

|

|

| 1. No power at outlet. | 1. Check power source. |

|

Motor does not run | 2. Defective power cord or plug. | 2. Repair or replace defective parts. |

|

3. Defective motor. | 3. Have motor repaired or replaced by an |

| |

|

| authorized service technician. |

|

|

|

|

|

| 1. Improper Base mounting. | 1. Make sure mounting hardware is |

|

|

| secure. |

|

Excessive Vibration | 2. Unsuitable mounting surface. | 2. The heavier the work bench, the less |

|

|

| vibration will occur. |

|

| 3. Loose motor mounting. | 3. Tighten motor mounting hardware. |

|

|

|

|

|

Blade not in line | 1. Blade holders not aligned. | 1. Loosen Blade Holder Hex Bolts and re- |

|

| align Upper and Lower Blade Holders. |

| |

with arm motion |

|

| |

| Tighten Hex Bolts. |

| |

|

|

| |

|

|

|

|

|

| REV 09/05 | |

SKU 93012 | For technical questions, please call | Page 14 |