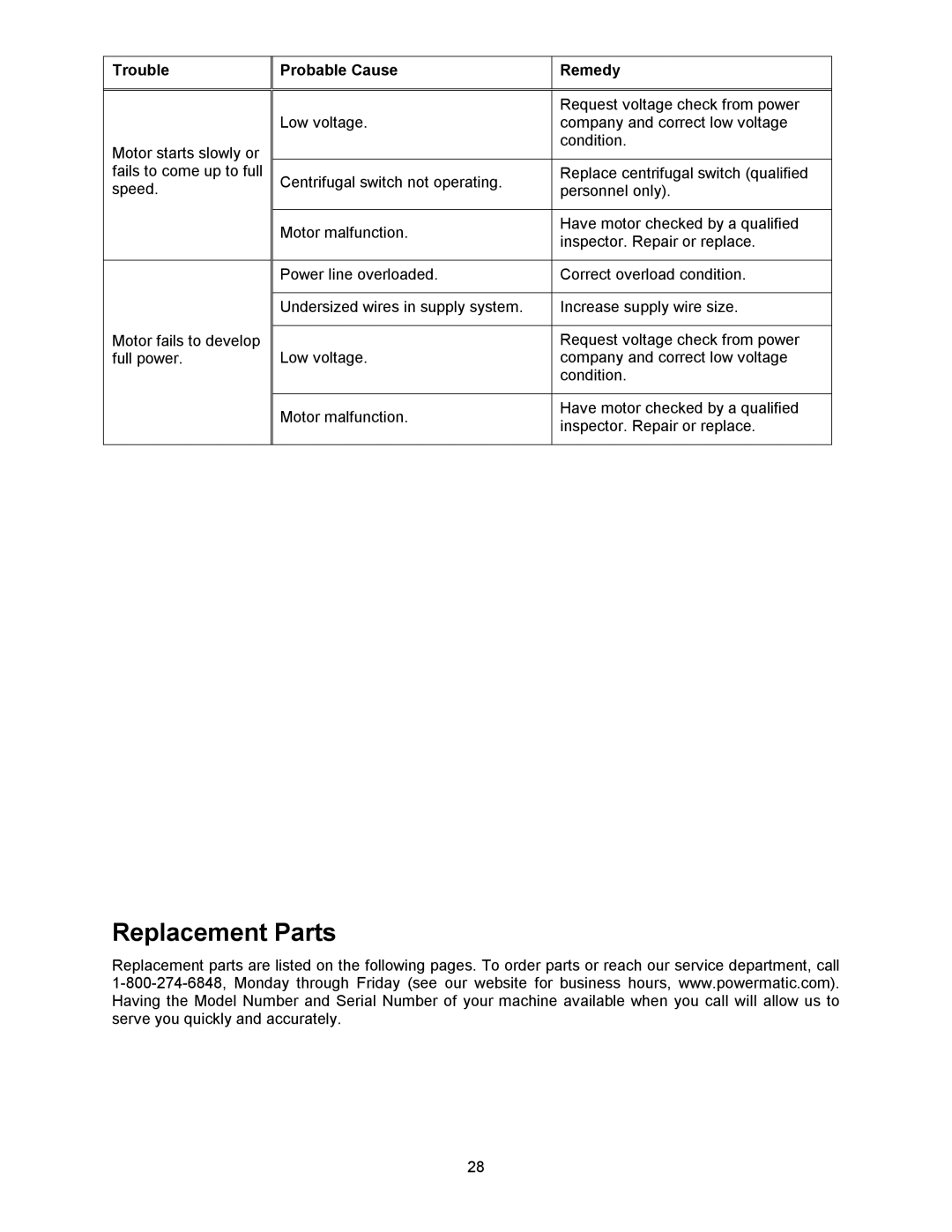

Troubleshooting

Trouble

Tablesaw will not start.

Excessive vibration.

Cuts

Motor stalls or workpiece binds or burns.

Cuts not true at 90 or 45 degrees.

Tilting or Raising handwheel difficult to turn.

Motor overheats

Probable Cause | Remedy | |

|

| |

No incoming power. | Check all plug connections. | |

|

| |

Fuse blown, or circuit breaker tripped. | Replace fuse, or reset circuit breaker. | |

|

| |

Cord damaged. | Replace cord. | |

|

| |

Tilting or Raising lock knobs not | Tighten lock knobs on handwheels. | |

tightened. | ||

| ||

|

| |

Tablesaw not resting evenly on floor. | Use shims as needed. | |

|

| |

Blade out of balance. | Replace blade. | |

|

| |

Pulley loose. | Check motor pulley and spindle | |

pulley. Tighten set screws if needed. | ||

| ||

|

| |

Belt is worn or frayed. | Replace belt. | |

|

| |

Motor not functioning properly. | Have motor checked by a qualified | |

inspector. Repair or replace. | ||

| ||

|

| |

Miter gauge out of adjustment. | ||

(pages 18 and 19). | ||

| ||

|

| |

Miter slot misaligned. | ||

|

| |

Excessive feed. | Reduce feed. | |

|

| |

Dull or incorrect blade. | Replace blade; use proper type of | |

blade for cut needed. | ||

| ||

|

| |

Miter slot misaligned. | ||

|

| |

Fence misaligned. | ||

manual). | ||

| ||

|

| |

Motor malfunction. | Have motor checked by a qualified | |

inspector. Repair or replace. | ||

| ||

|

| |

Stop screws not set properly. | ||

|

| |

Lock knob not released. | Loosen lock knob. | |

|

| |

Worm and worm gear segment caked | Clean and | |

with sawdust and pitch. | gear segment. | |

|

| |

Worm and worm gear segment out of | ||

alignment. | ||

| ||

|

| |

| Identify and correct overload | |

Motor overloaded. | condition, e.g. excessive feed rate of | |

| stock. | |

|

| |

Improper cooling of motor; lack of air | Clean sawdust from fan and duct | |

areas of motor. | ||

circulation. |

| |

|

|

27