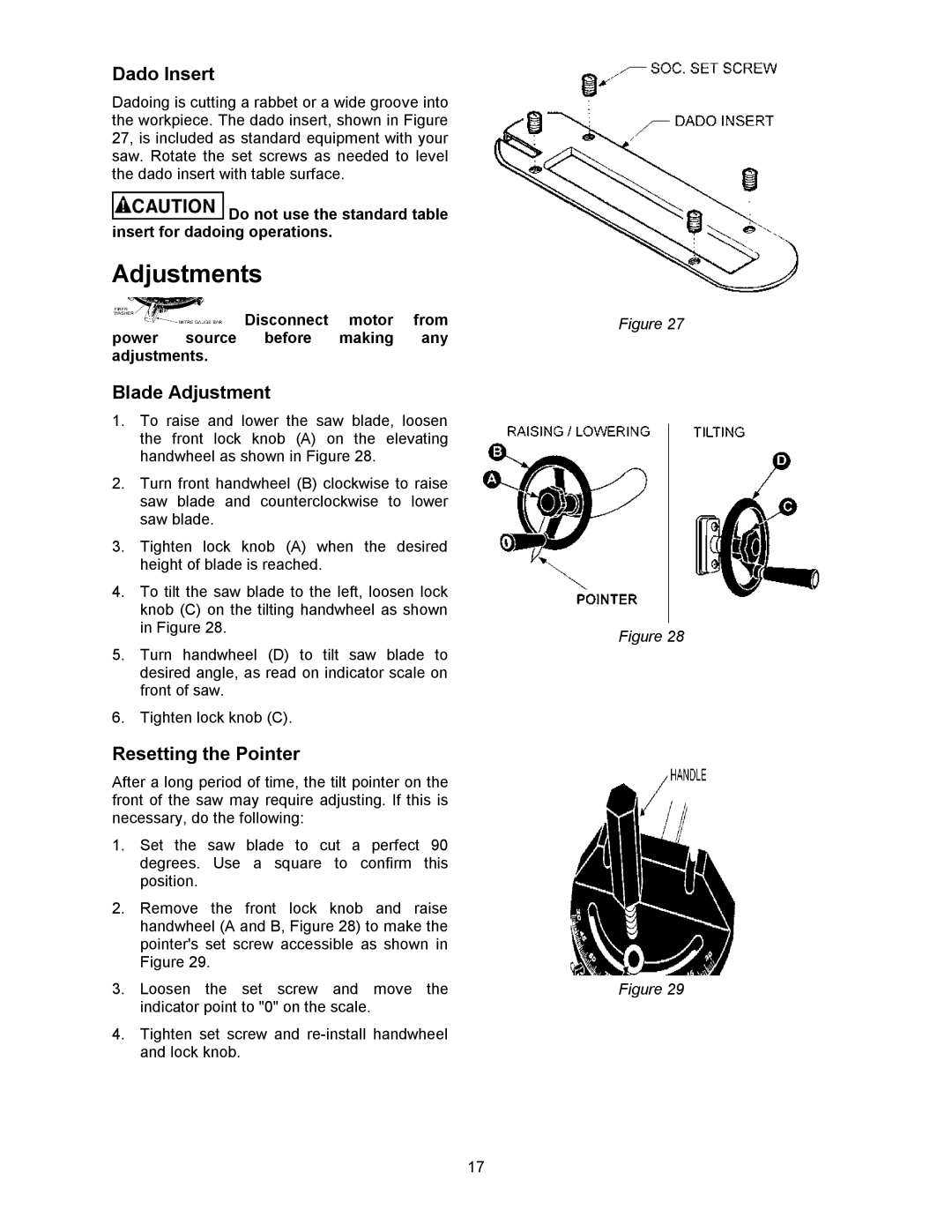

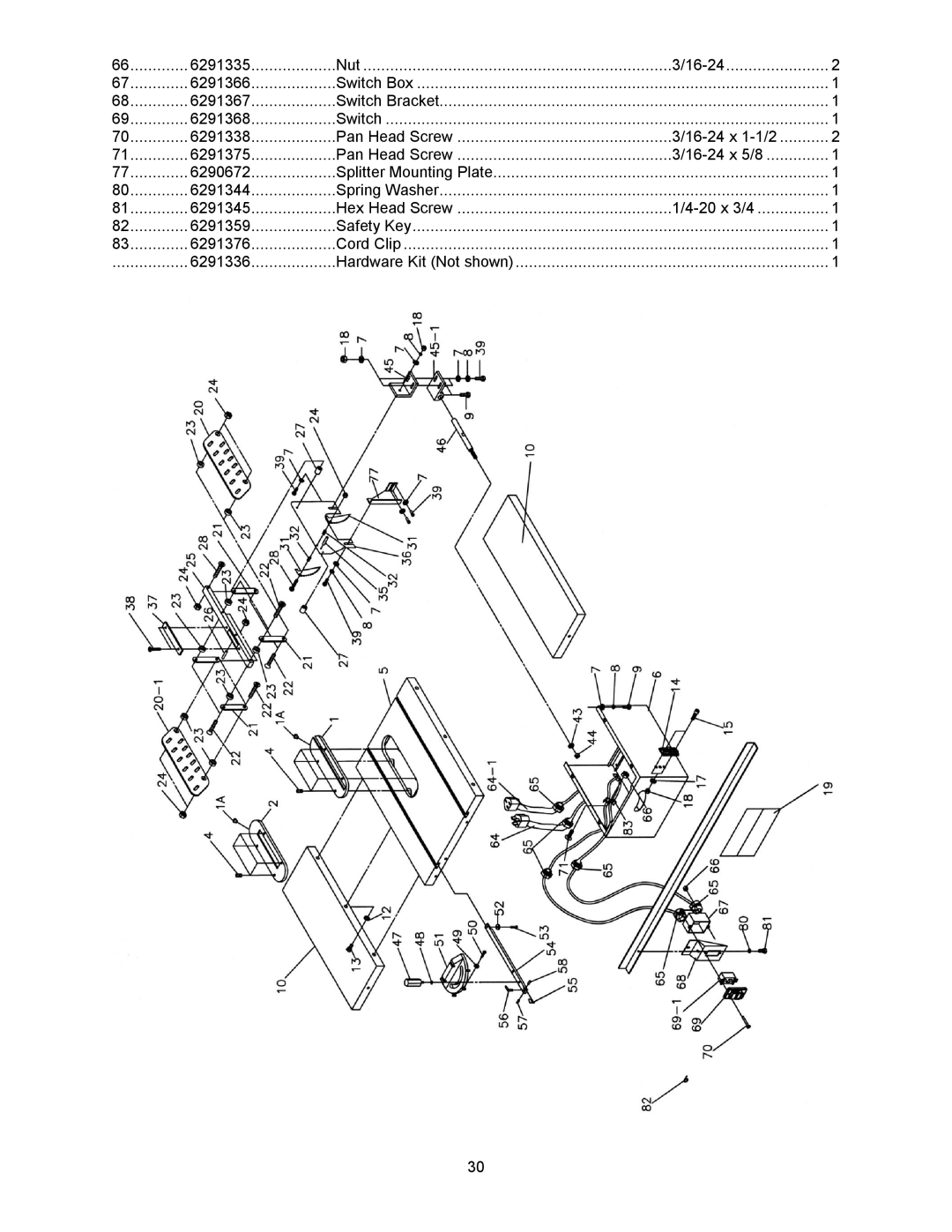

45 and 90 Degree Positive Stops

Convenient access to these adjustments will be from the back side of the saw.

1.Disconnect machine from power source.

2.Raise the saw blade to its maximum height.

3.Set the blade at 90 degrees to the table by turning the blade tilting handwheel clockwise as far as it will go.

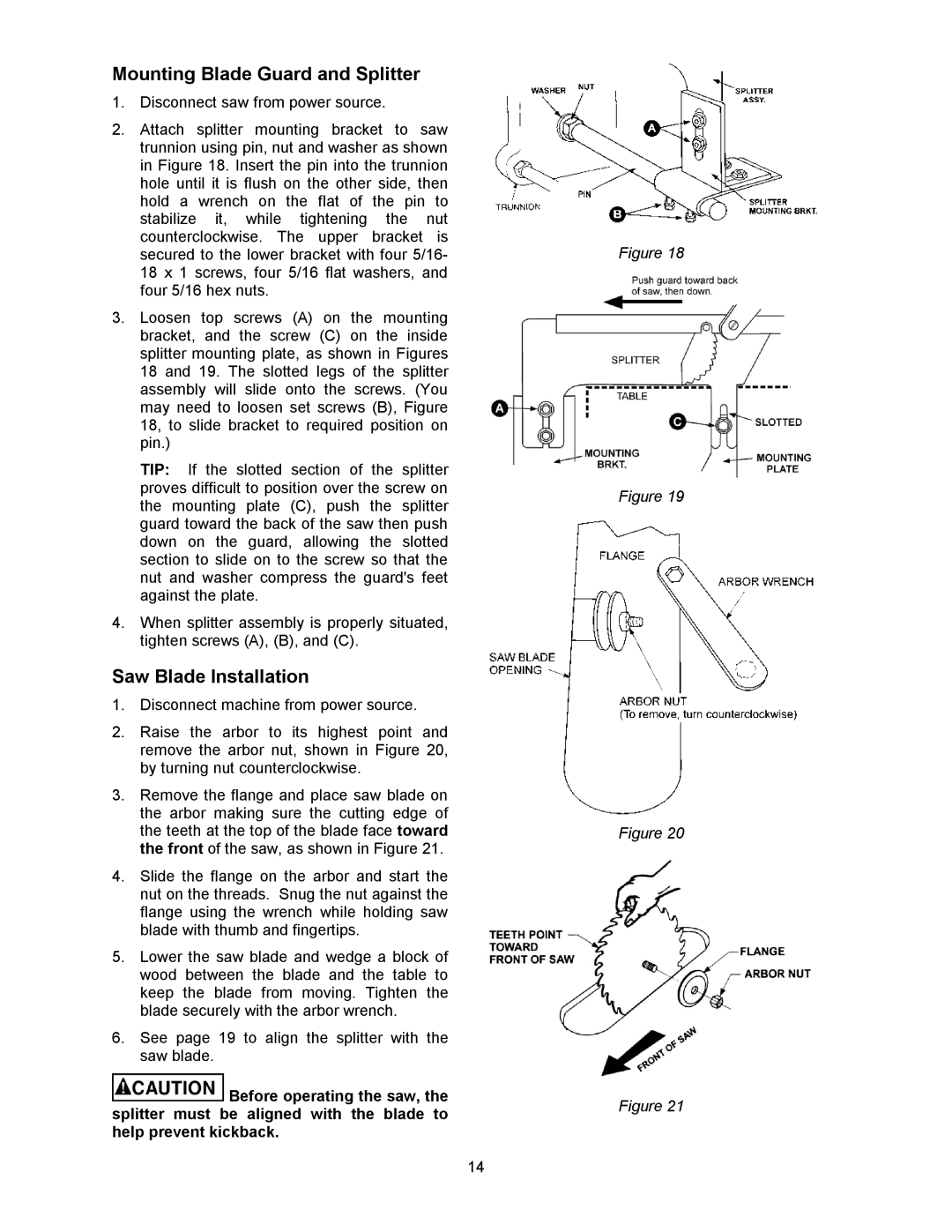

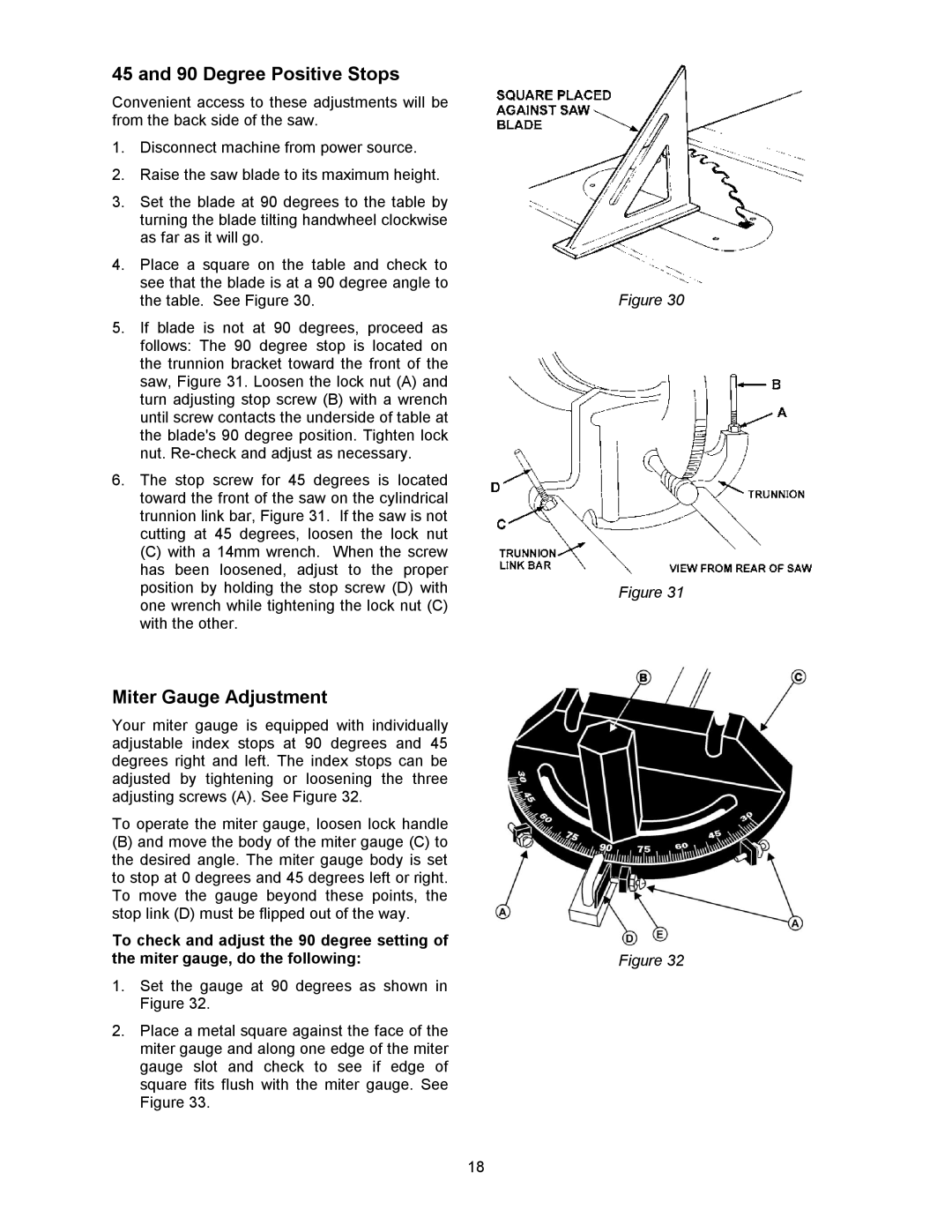

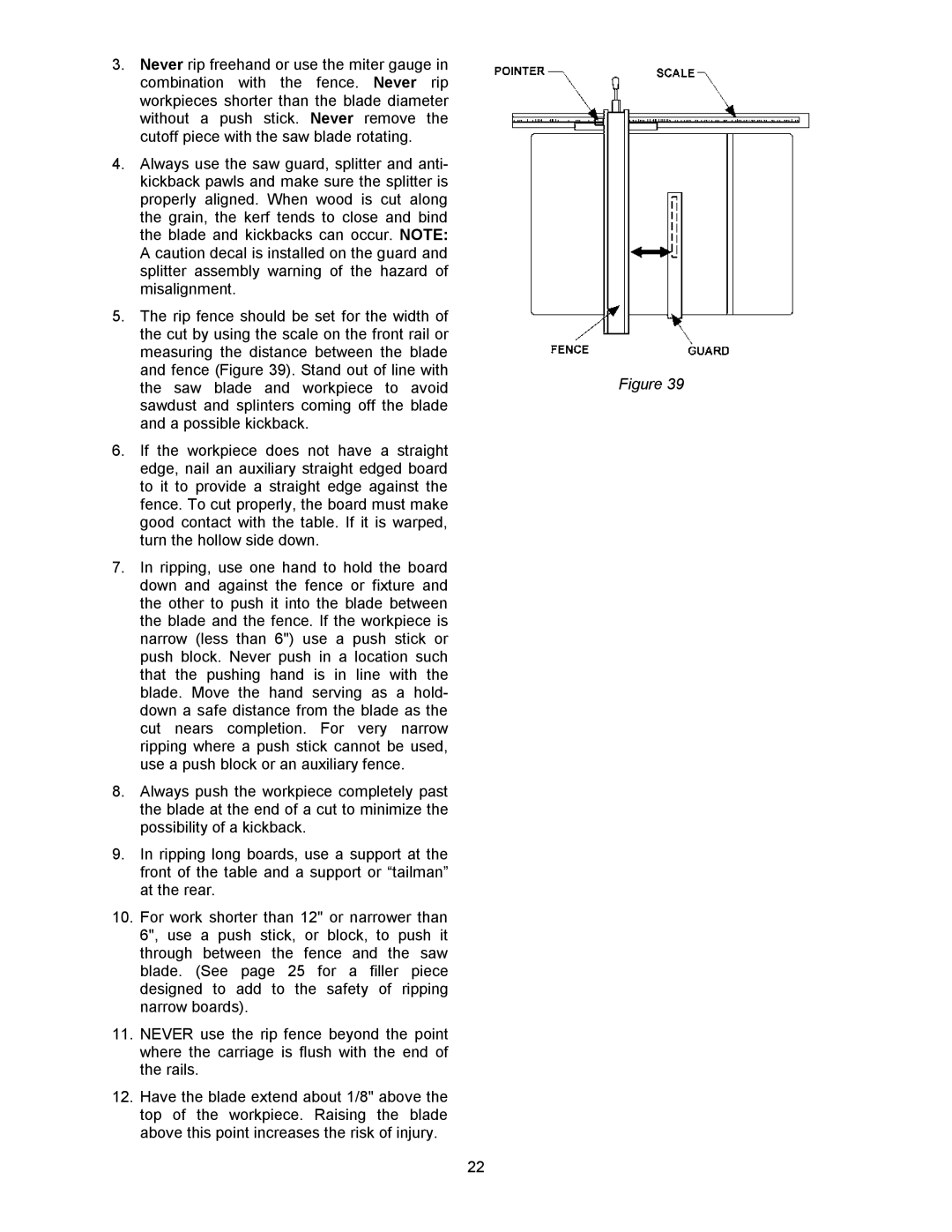

4.Place a square on the table and check to see that the blade is at a 90 degree angle to the table. See Figure 30.

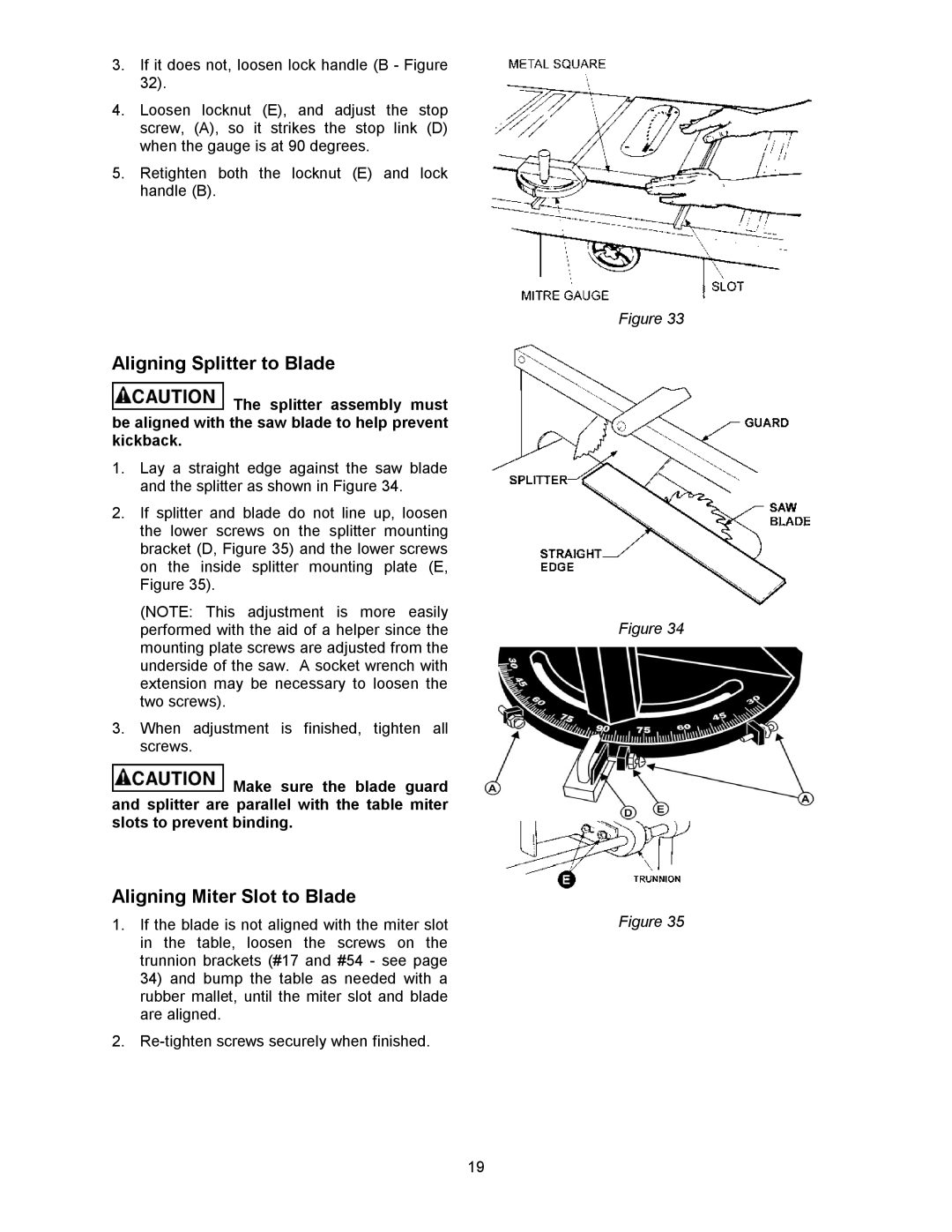

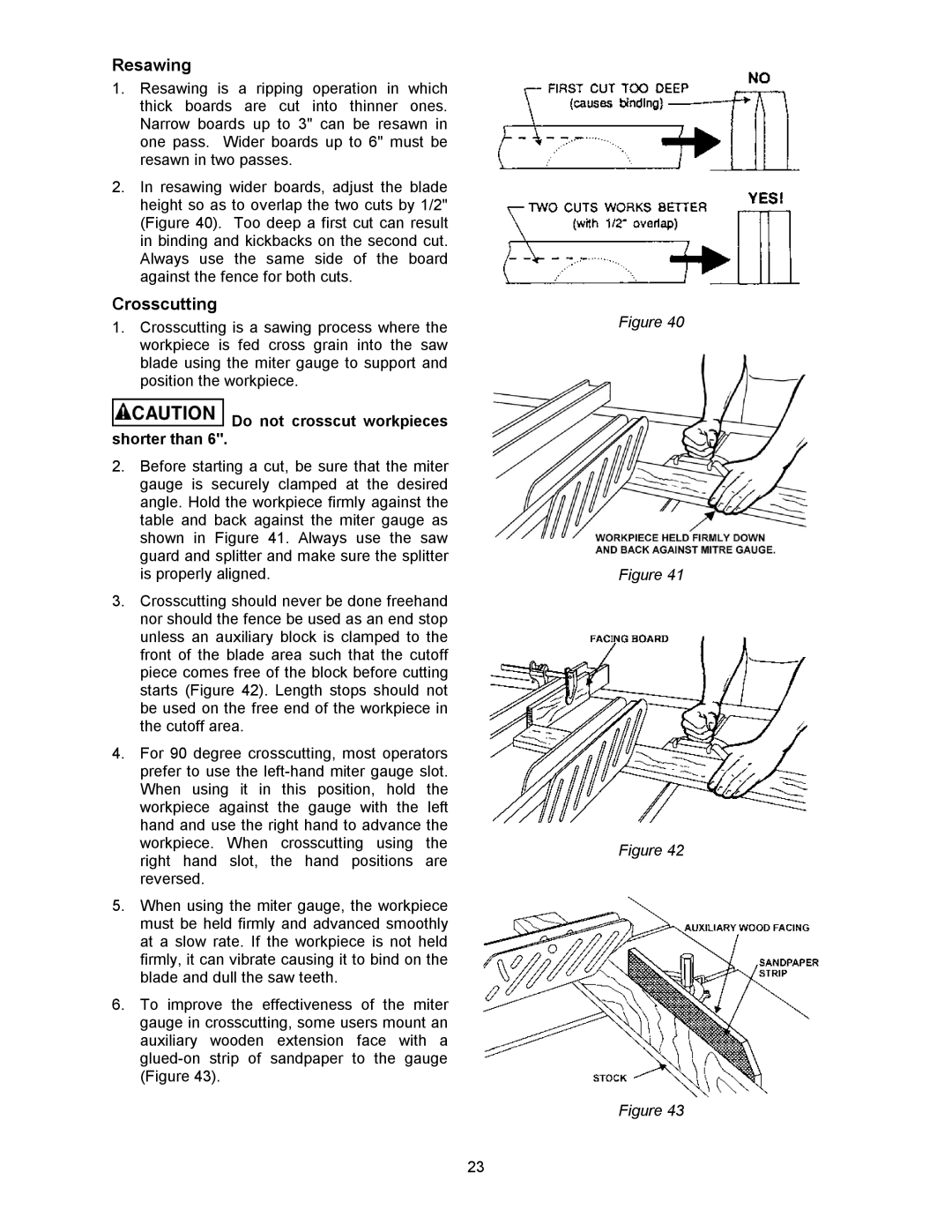

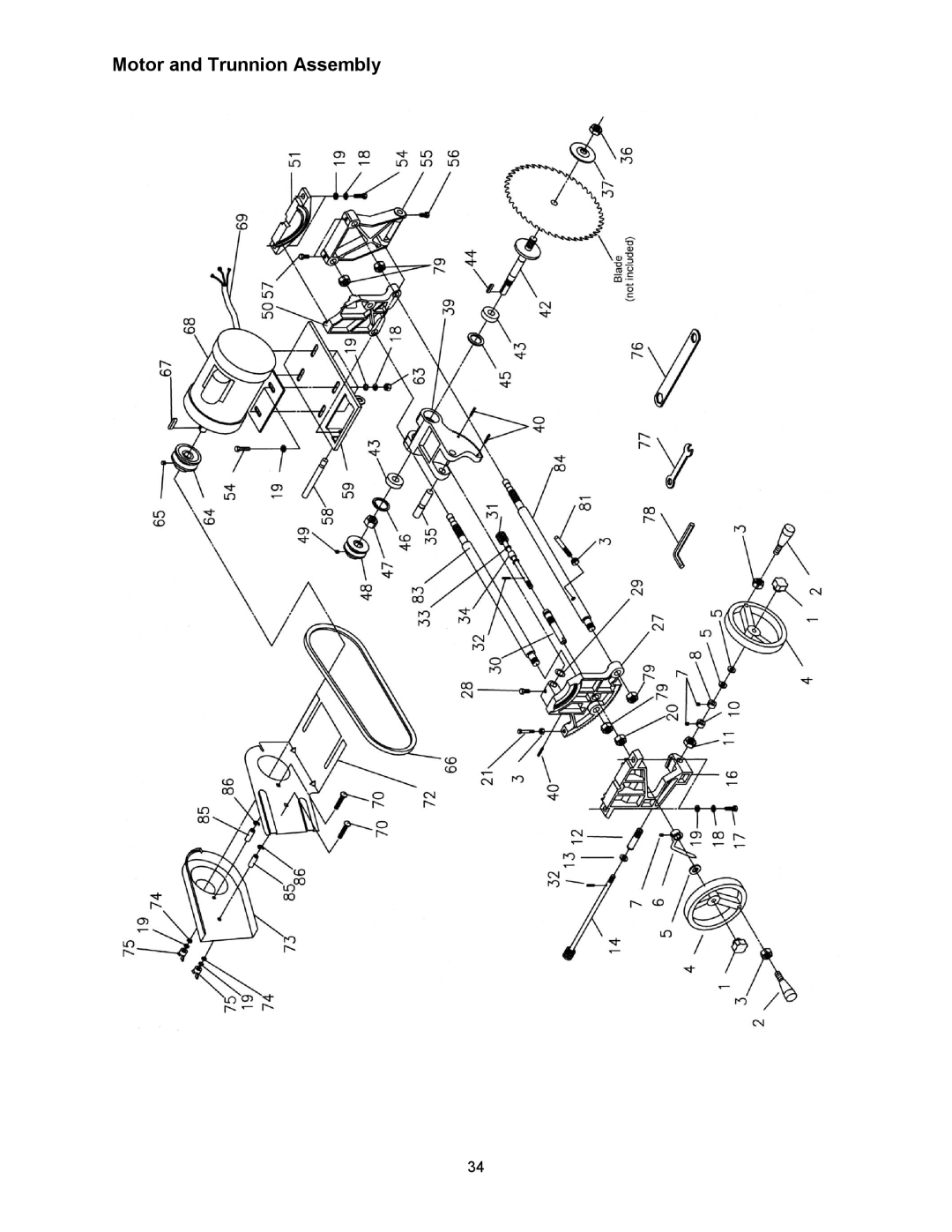

5.If blade is not at 90 degrees, proceed as follows: The 90 degree stop is located on the trunnion bracket toward the front of the saw, Figure 31. Loosen the lock nut (A) and turn adjusting stop screw (B) with a wrench until screw contacts the underside of table at the blade's 90 degree position. Tighten lock nut.

6.The stop screw for 45 degrees is located toward the front of the saw on the cylindrical trunnion link bar, Figure 31. If the saw is not cutting at 45 degrees, loosen the lock nut

(C)with a 14mm wrench. When the screw has been loosened, adjust to the proper position by holding the stop screw (D) with one wrench while tightening the lock nut (C) with the other.

Miter Gauge Adjustment

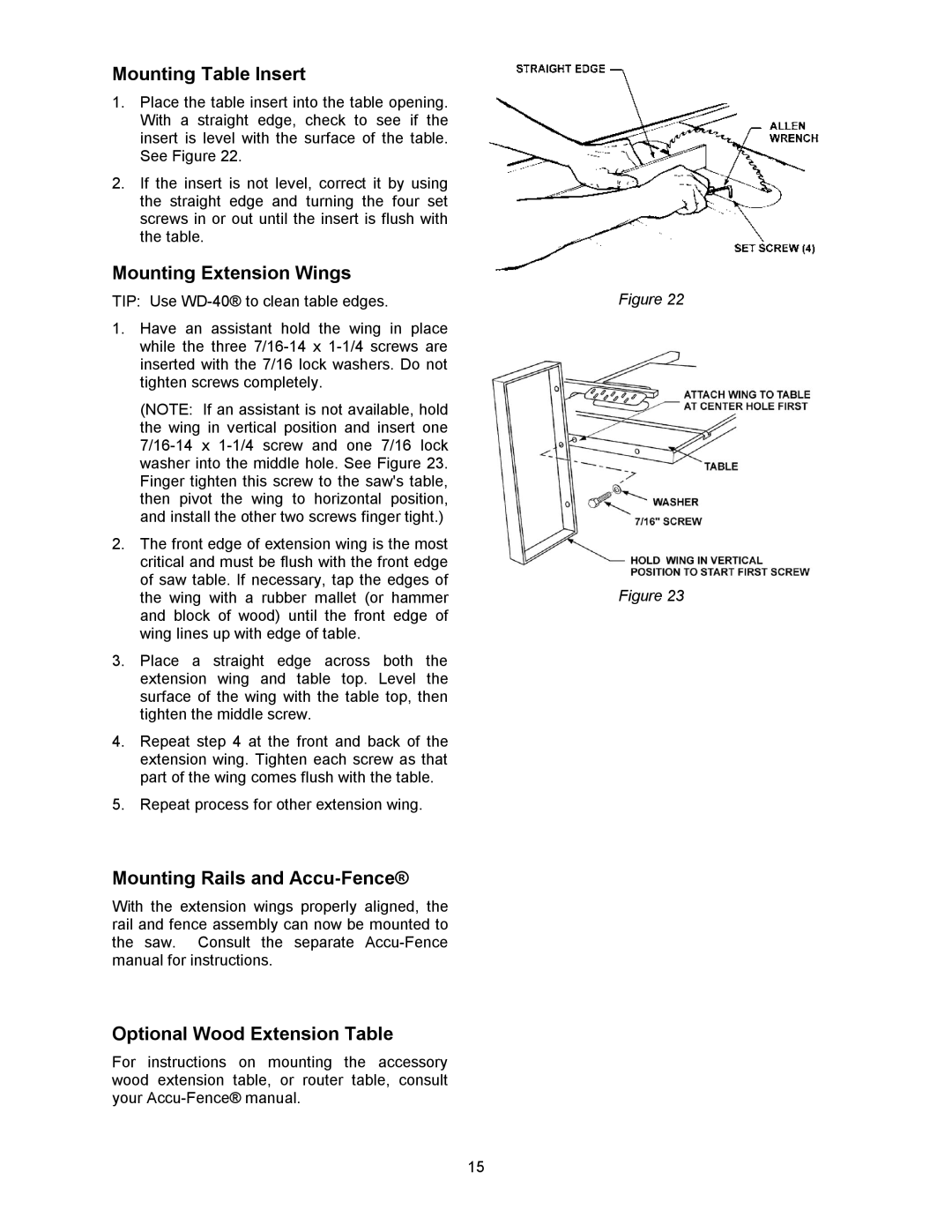

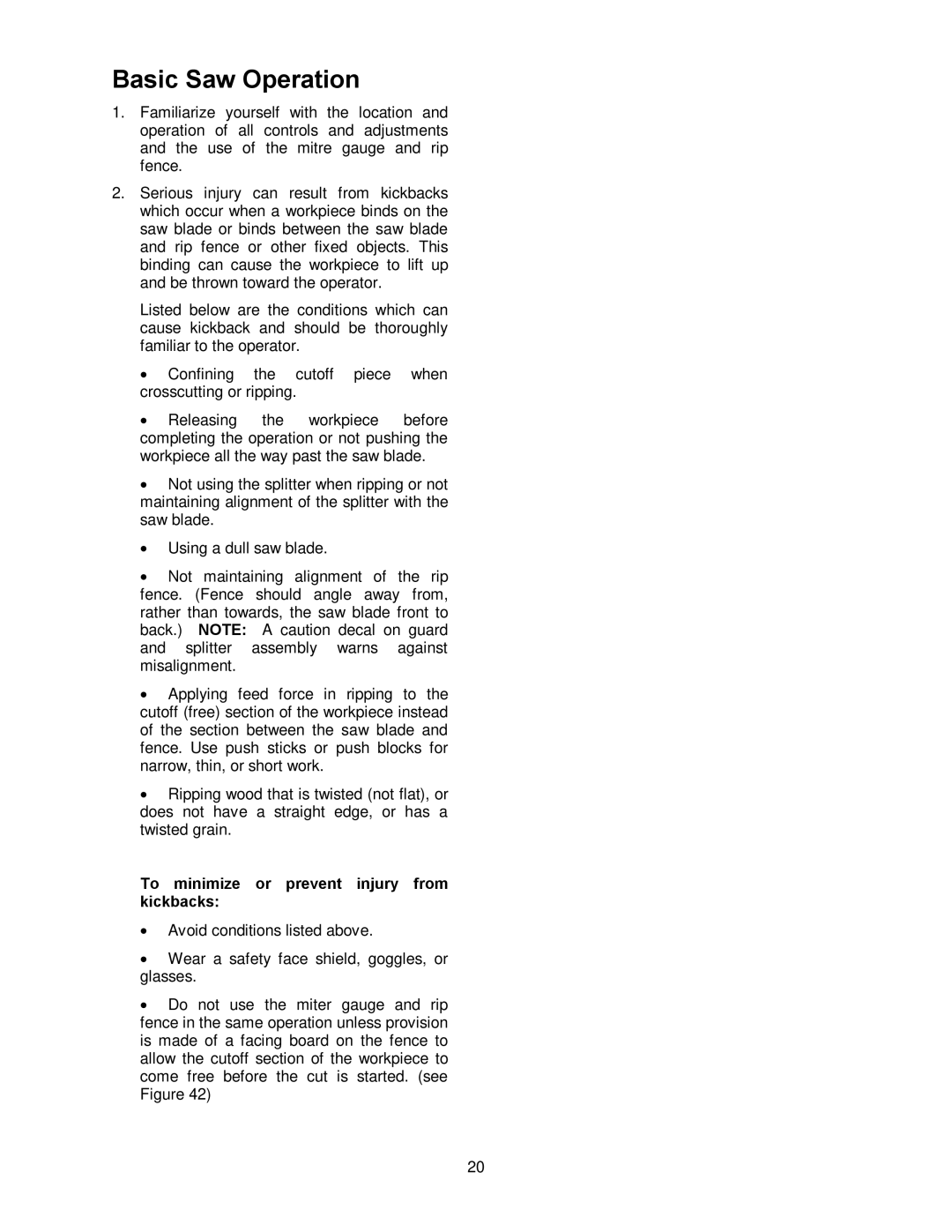

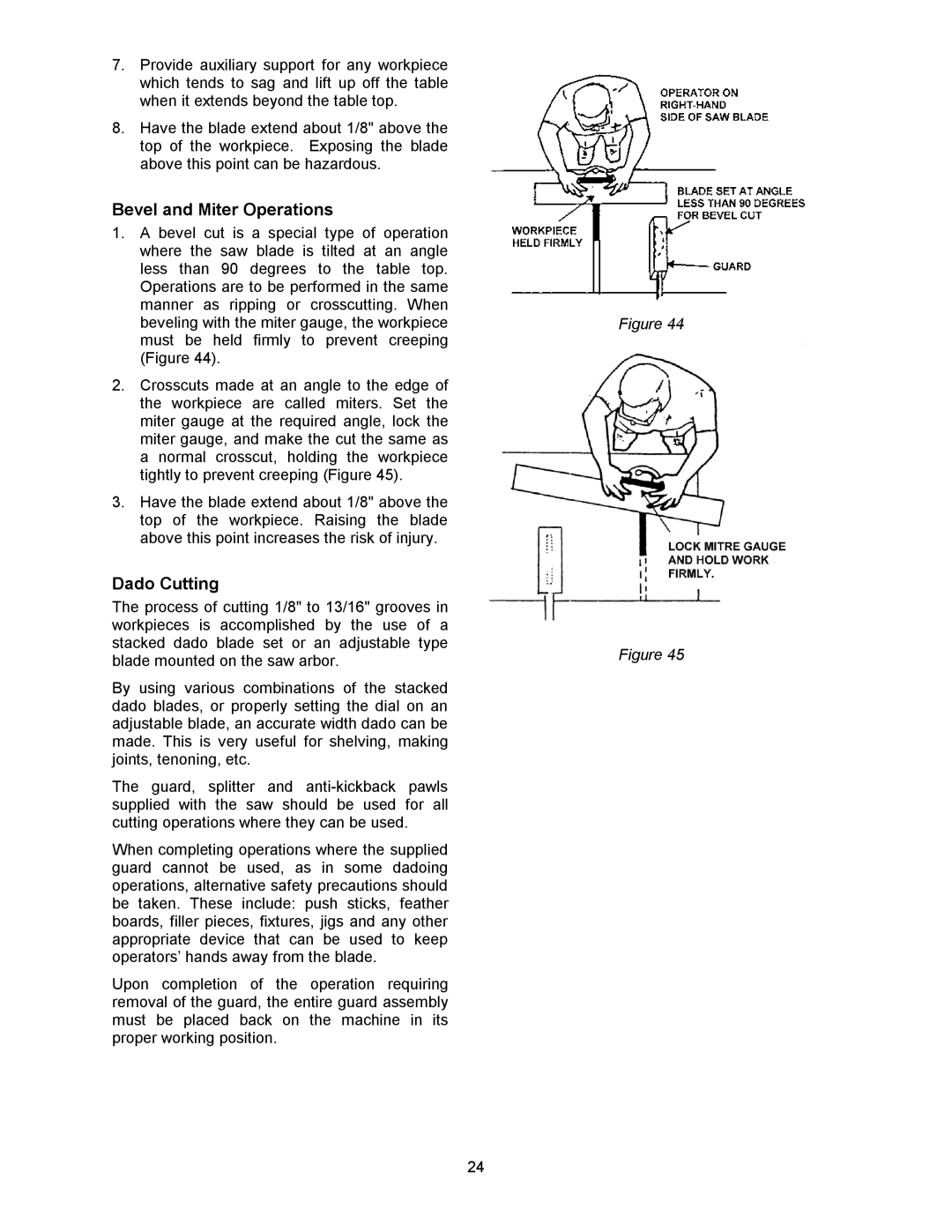

Your miter gauge is equipped with individually adjustable index stops at 90 degrees and 45 degrees right and left. The index stops can be adjusted by tightening or loosening the three adjusting screws (A). See Figure 32.

To operate the miter gauge, loosen lock handle

(B)and move the body of the miter gauge (C) to the desired angle. The miter gauge body is set to stop at 0 degrees and 45 degrees left or right. To move the gauge beyond these points, the stop link (D) must be flipped out of the way.

To check and adjust the 90 degree setting of the miter gauge, do the following:

1.Set the gauge at 90 degrees as shown in Figure 32.

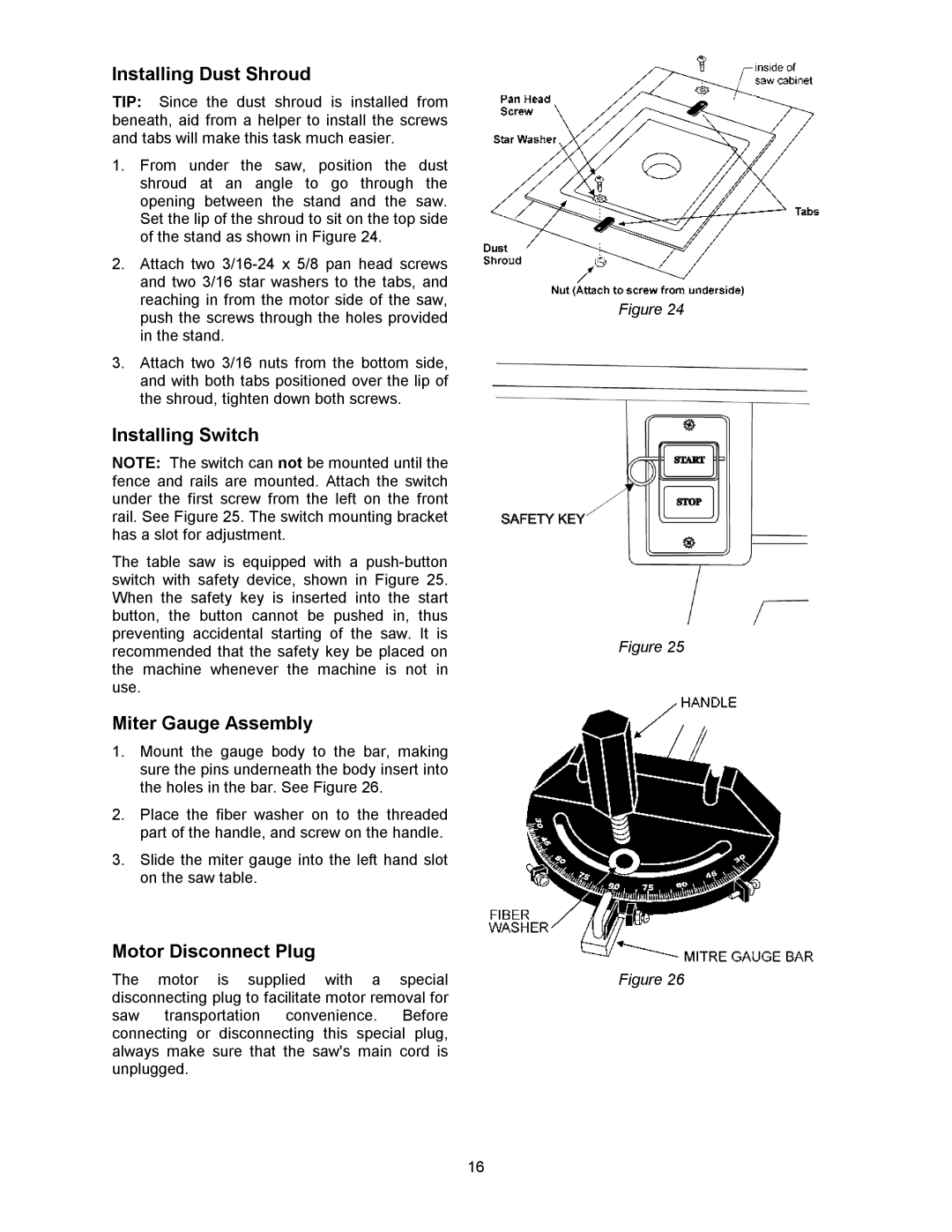

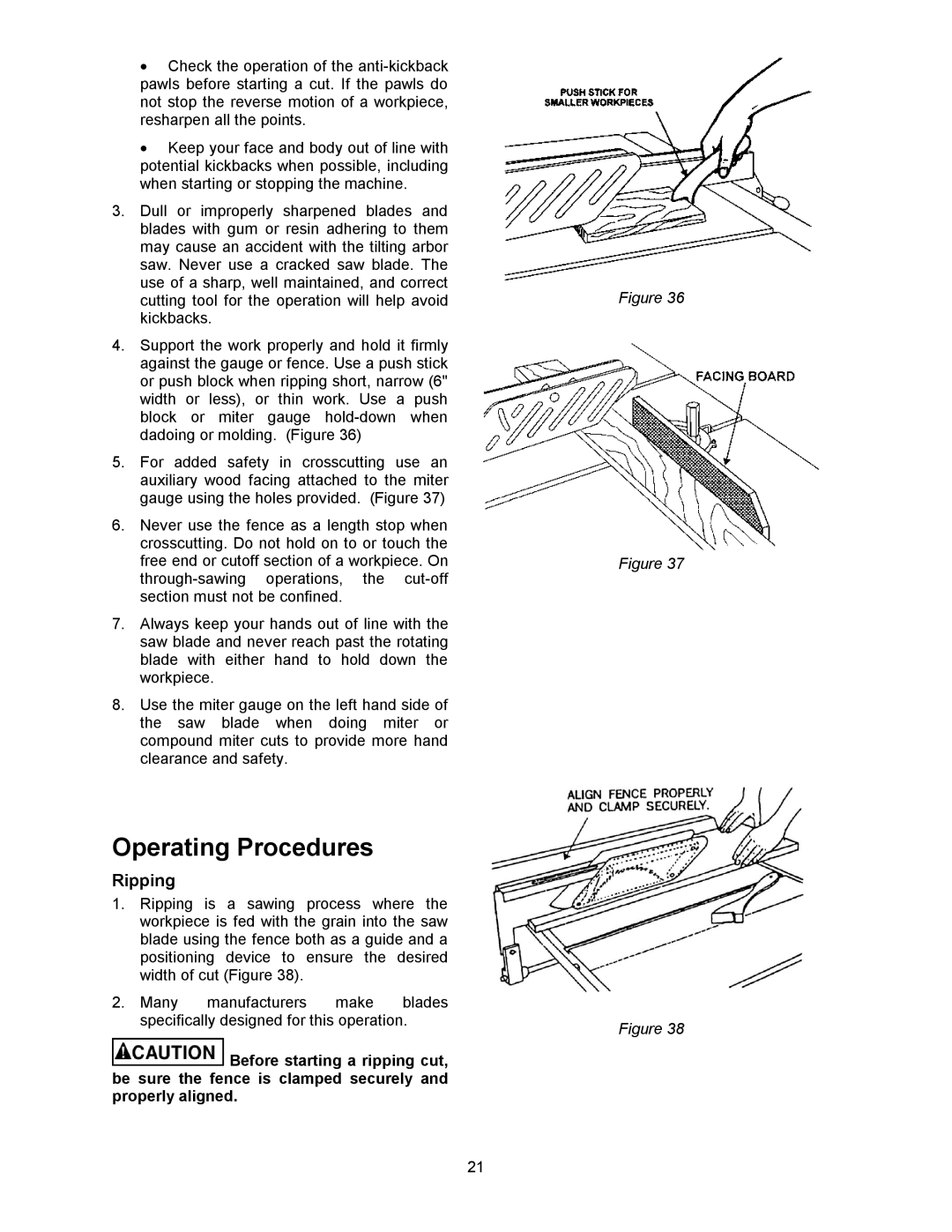

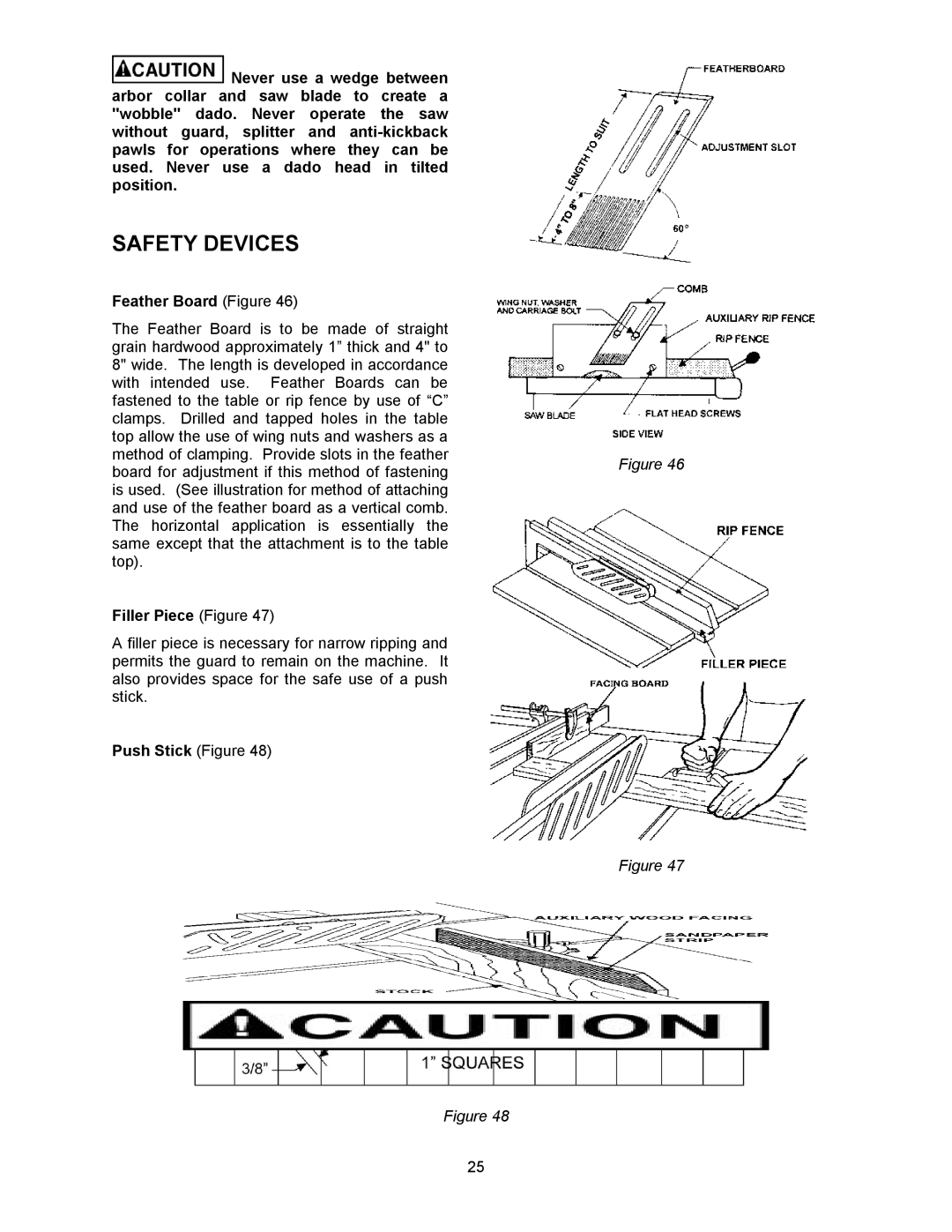

2.Place a metal square against the face of the miter gauge and along one edge of the miter gauge slot and check to see if edge of square fits flush with the miter gauge. See Figure 33.

Figure 30

Figure 31

Figure 32

18