Zero-Clearance

Insert

A

A

If you plan to use a standard blade with a zero- clearance insert, additional modifications will need to be made in order to install the scoring blade and riving knife.

If you must use this saw to cut the dimen- | |

sions of the | |

fabricate in these instructions, make sure | |

you DO NOT make any cuts while the | |

included table insert is removed. THIS IS | |

DANGEROUS. You must | |

insert, reassemble all saw components, and | |

remove all tools before cutting. |

|

Items Needed | Qty |

Table Saw | 1 |

Drill Press | 1 |

Sander | 1 |

Drill Bits 7⁄32" and 13⁄32" | 1 Each |

Plywood/Hardwood Piece 14" x 11⁄16" x 3⁄4" | 1 |

Bandsaw or Jigsaw (Optional) | 1 |

Clamp (Optional) | 1 |

To make a | |

these steps: |

|

1.DISCONNECT SAW FROM POWER

2.Lower the main blade all the way, remove the blade guard, riving knife, and scoring blade. After removing the scoring blade, reinstall and tighten the scoring blade flanges and arbor nut.

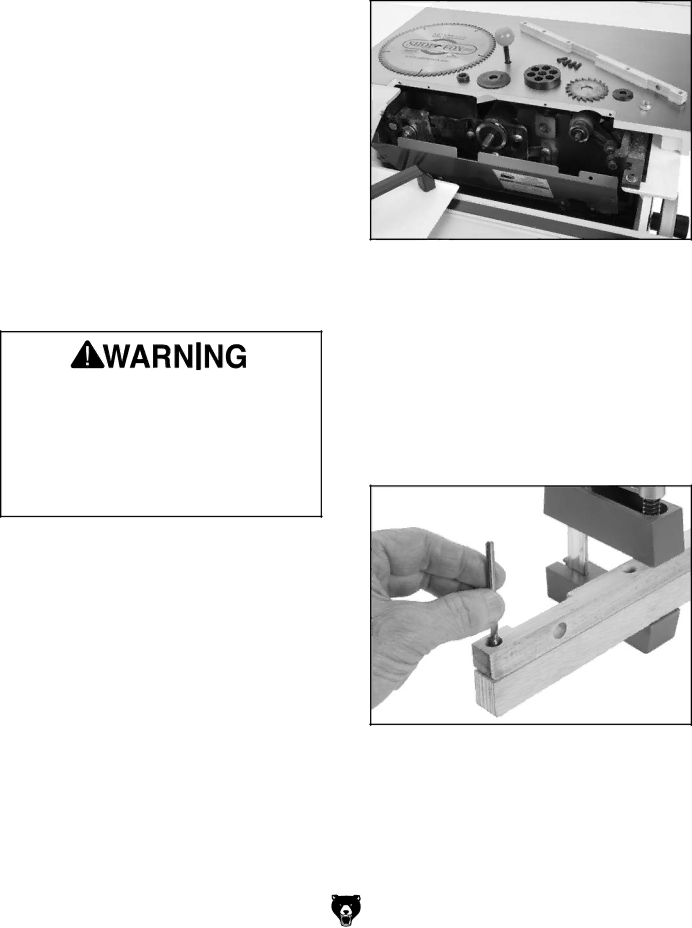

3.Remove the main blade and the spacer block behind it (see Figure 92).