ASSEMBLY

UNPACKING

This product requires assembly.

Carefully lift the saw from the carton and place it on a level work surface.

WARNING:

Do not use this product if any parts on the Loose Parts List are already assembled to your product when you unpack it. Parts on this list are not as- sembled to the product by the manufacturer and require customer installation. Use of a product that may have been improperly assembled could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

The saw is factory set for accurate cutting. After assembling it, check for accuracy. If shipping has influ- enced the settings, refer to specific procedures explained in this manual.

If any parts are damaged or missing, please call

WARNING:

If any parts are damaged or missing do not oper- ate this tool until the parts are replaced. Use of this product with damaged or missing parts could result in serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

WARNING:

To avoid serious personal injury, always make sure the table saw is securely mounted to a workbench or an approved leg stand. NEVER operate the saw on the floor.

Mounting Holes

The table saw must be mounted to a firm supporting, waist high surface such as a workbench or leg stand. Four bolt holes have been provided in the saw’s base for this purpose. Each of the four mounting holes should be bolted securely using 1/4 in. machine bolts, lock washers, and hex nuts (not included). Bolts should be of sufficient length to accommodate the saw base, lock washers, hex nuts, and the thickness of the workbench. Tighten all four bolts securely.

Carefully check the workbench after mounting to make sure that no movement can occur during use. If any tipping, slid- ing, or walking is noted, secure the workbench to the floor before operating.

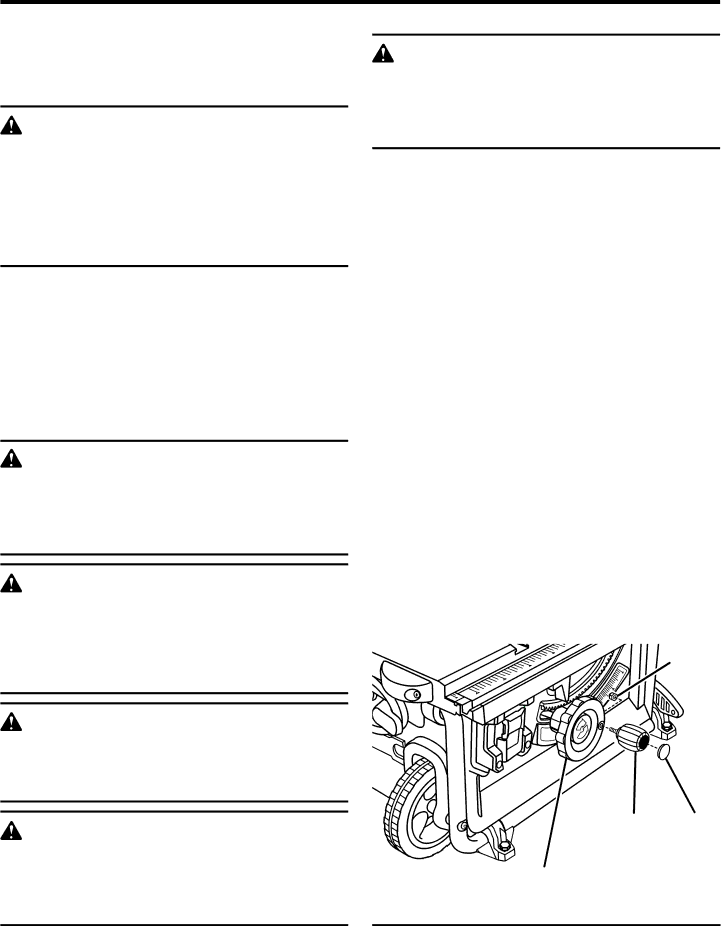

to install the Handle assembly

See Figure 6.

Lift the end cap off the handle assembly using a flat blade screwdriver.

Hold the nylok nut securely and turn the screw counter- clockwise to remove the nut completely.

NOTE: Do not remove the screw from the handle or the washer from the end of the screw.

Place the nylok nut into the recessed hole on the back of the height/bevel adjusting handwheel and hold in place.

Slide the handle, screw, and washer into the hole on the height/bevel adjusting handwheel.

Using a flathead screwdriver, turn the screw clockwise and tighten in place.

Push the end cap back in place on the end of the handle.

NUT

WARNING:

Do not connect to power supply until assembly is complete. Failure to comply could result in acci- dental starting and possible serious personal injury.

WARNING:

Never stand directly in line with the blade or allow hands to come closer than 3 in. to the blade. Do not reach over or across the blade. Failure to heed this warning can result in serious personal injury.

HANDLE | END |

assembly | cap |

HEIGHT/bevel |

|

ADJUSTING |

|

HANDWHEEL | Fig. 6 |

15