CUTTING

CROWN MOULDING

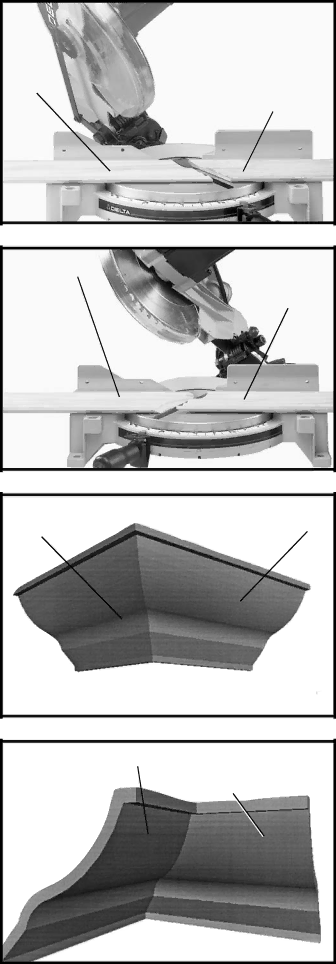

One of the many features of your saw is the ease of cutting crown moulding.The following is an example of cutting both inside and outside corners on 52/38 degree wall angle crown moulding. NOTE: When cutting 45 degree wall angle crown moulding, the following procedure for inside and outside corners is the same with the excep- tion that the bevel position will always be at 30 degrees and the miter position will be

1. | Move the table to the |

tion and lock the table in position. NOTE: A triangle indi- | |

cator is provided on the miter scale to find this angle | |

quickly. | |

2. | Tilt the saw blade to the |

position and tighten bevel lock handle. NOTE: A triangle | |

indicator is provided on the bevel scale to find this angle | |

quickly. | |

3. | Place the crown moulding on the table with the |

CEILING EDGE of the moulding against the fence, and | |

make the cut, as shown in Fig. 39. NOTE: The piece of | |

crown moulding used for the outside corner will always | |

be on the right hand side of the blade, as shown at (A) | |

Fig. 39. The piece of crown moulding used for the inside | |

corner will always be on the left hand side of the blade, | |

as shown at (B) Fig. 39. | |

4. | To make the matching halves of the inside and out- |

B

A

Fig. 39

D

C

Fig. 40

side corners, simply rotate the table to the |

degree left miter position and tighten table lock handle. |

NOTE: A triangle indicator is provided on the miter scale |

to find this angle quickly. |

5. Place the crown moulding on the table with the |

WALL EDGE of the crown moulding against the fence |

and make the cut. Again, the piece of crown moulding |

used for the outside corner will always be on the right |

side of the blade, as shown at (C) Fig. 40. The piece of |

crown moulding used for the inside corner will always be |

on the left side of the blade, as shown at (D) Fig. 40. |

C

A

6. | Fig. 41, illustrates the two outside corner pieces; (A) |

being the piece cut at (A) Fig. 41, and (C) being the piece | |

cut at (C) Fig. 41. | |

7. | Fig. 42, illustrates the two inside corner pieces; (B) |

being the piece cut at (B) Fig. 42, and (D) being the piece | |

cut at (D) Fig. 42. | |

Fig. 41

B

D

Fig. 42

16