.A complete Parts List is available at www.HobartWelders.com

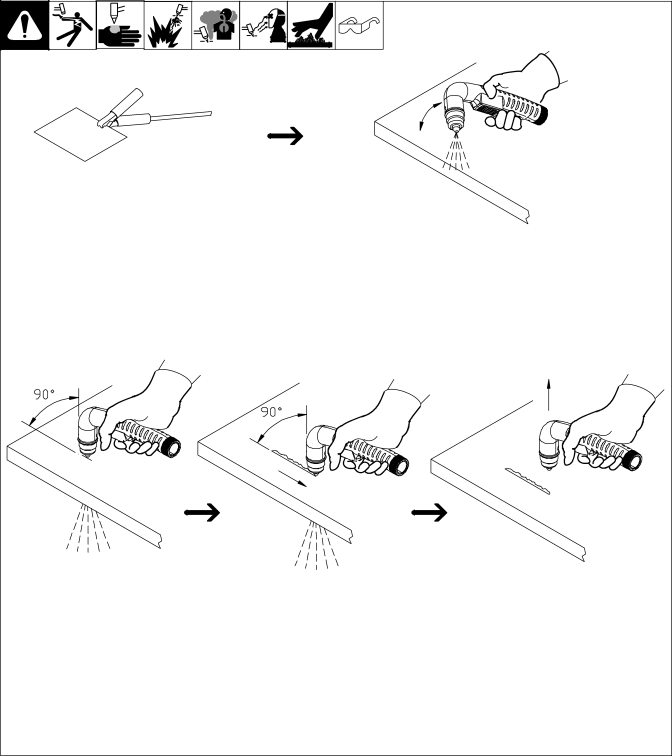

5-6. Sequence Of Piercing Operation

Y The pilot arc starts immediately when trigger is pressed.

Connect work clamp to a clean,

Hold torch at an angle to

the workpiece. Press trigger. Pilot arc starts.

Move torch to upright | Maintain torch position | Release trigger. Postflow cooling |

° | and continue cutting. | continues after releasing trigger. |

position 90 to surface. |

| . Postflow must finish before |

Start cutting when arc |

| |

pierces workpiece. |

| trigger will restart pilot arc. |

|

|

Ref. 803