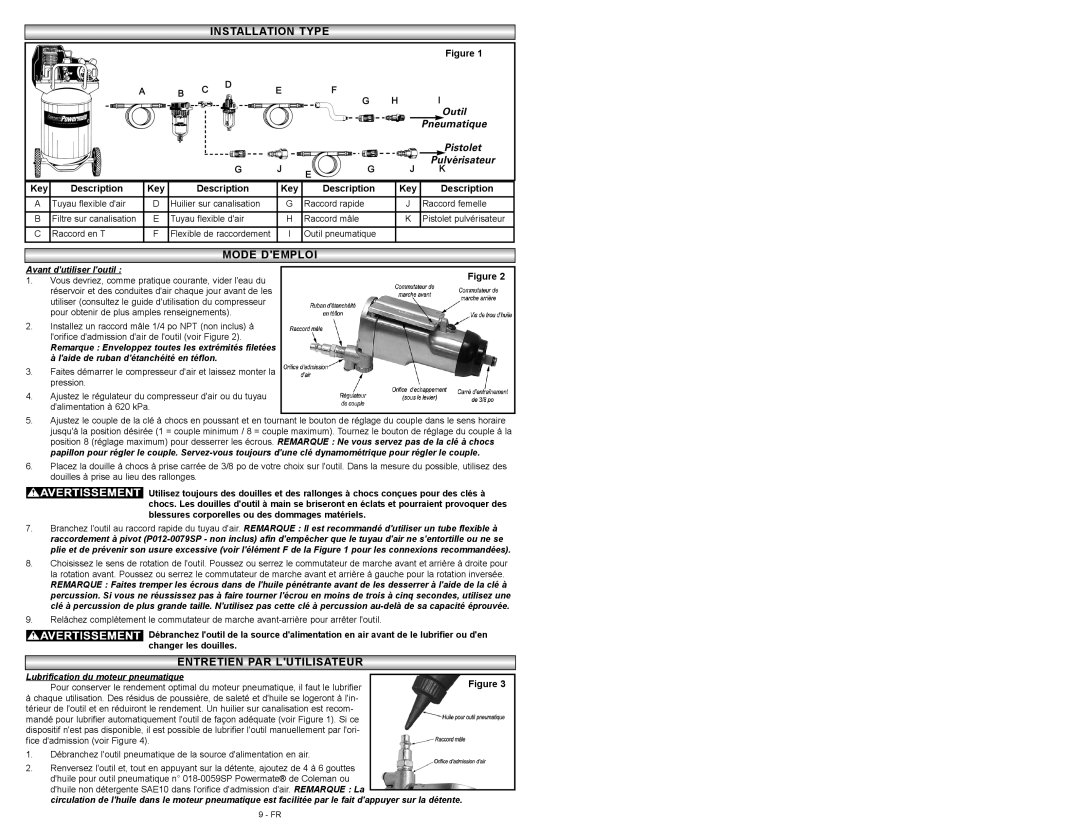

Air Motor Lubrication (continued)

2.Turn the tool upside down and while depressing the trigger, add

3.Reconnect the tool to the air supply, cover the exhaust port end with a towel and run in forward and reverse directions for approximately 30 seconds to remove excess oil.

NOTE: If the tool remains sluggish after it has been lubricated, the internal components may need to be cleaned.

To Clean:

Disconnect the air tool from the air supply and pour or spray a generous amount of

![]() After oiling or cleaning, cover the exhaust port with a towel and operate the tool for a few seconds to safely remove the excess oil. Clean the handle and surface of the tool of any oil residue. Failure to cover the exhaust port and clean the tool, can

After oiling or cleaning, cover the exhaust port with a towel and operate the tool for a few seconds to safely remove the excess oil. Clean the handle and surface of the tool of any oil residue. Failure to cover the exhaust port and clean the tool, can

result in serious injury. Note: Keep the towel away from moving parts!

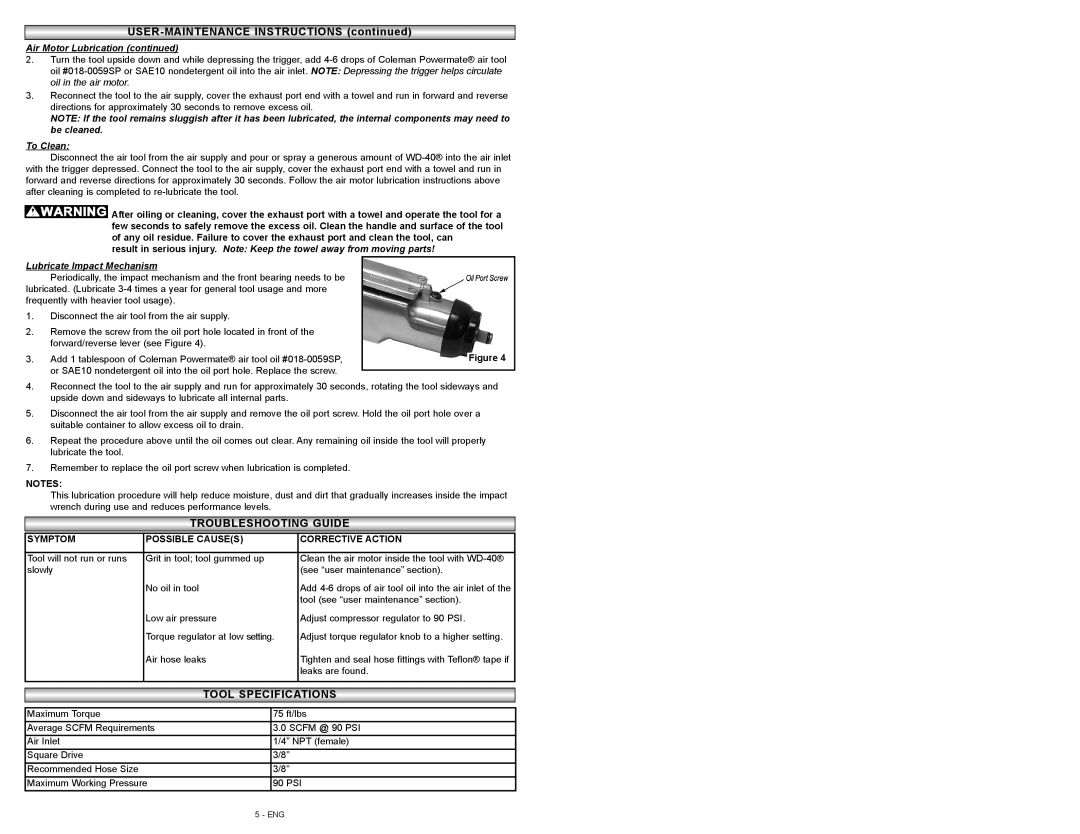

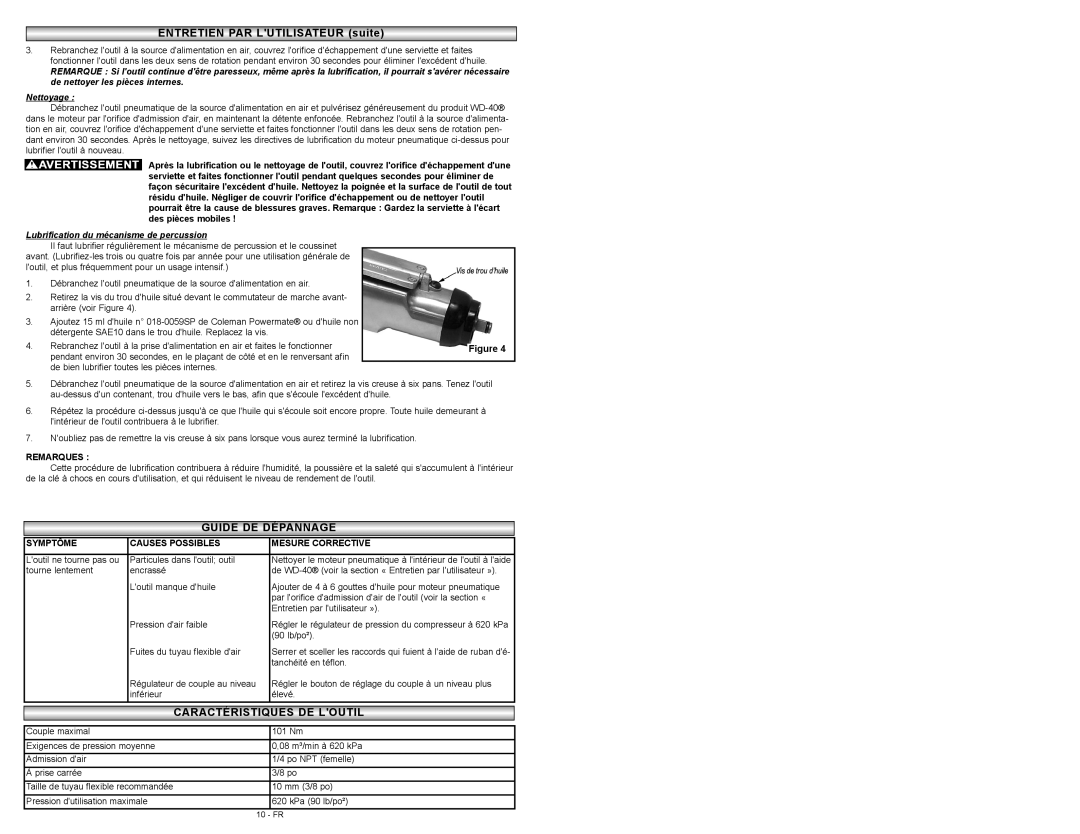

Lubricate Impact Mechanism

Periodically, the impact mechanism and the front bearing needs to be lubricated. (Lubricate

1.Disconnect the air tool from the air supply.

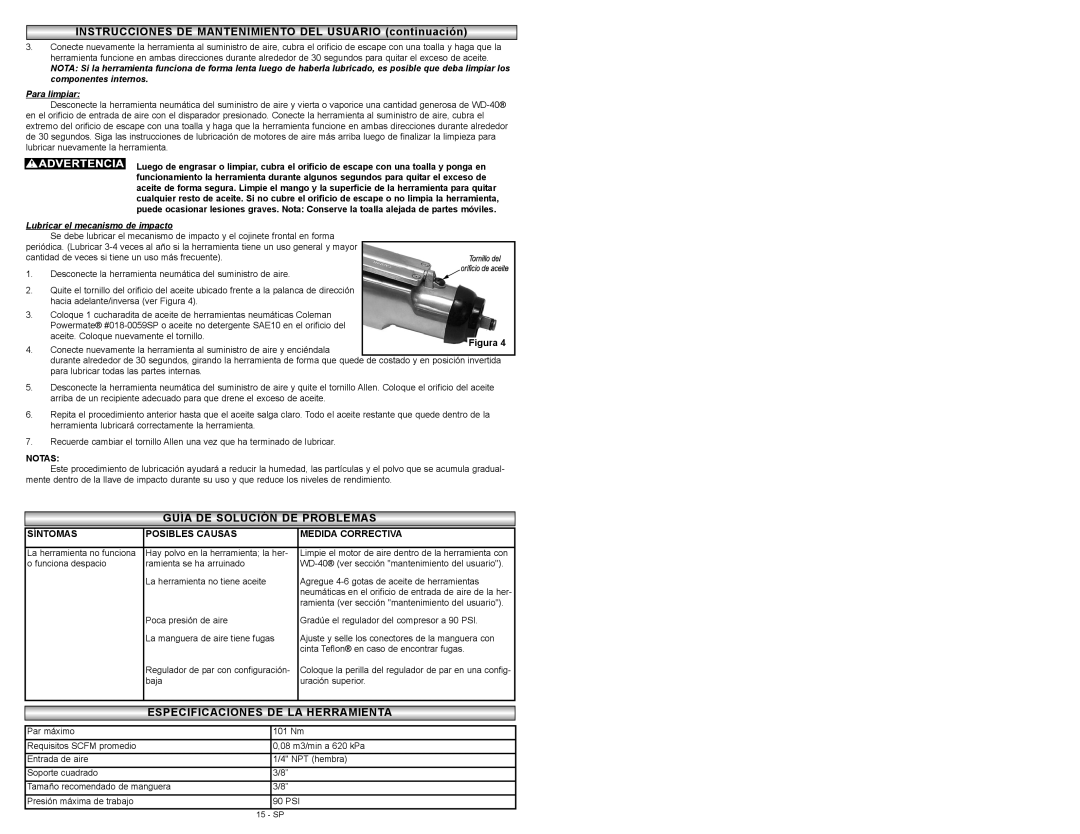

2.Remove the screw from the oil port hole located in front of the forward/reverse lever (see Figure 4).

3.Add 1 tablespoon of Coleman Powermate® air tool oil

Figure 4

4.Reconnect the tool to the air supply and run for approximately 30 seconds, rotating the tool sideways and upside down and sideways to lubricate all internal parts.

5.Disconnect the air tool from the air supply and remove the oil port screw. Hold the oil port hole over a suitable container to allow excess oil to drain.

6.Repeat the procedure above until the oil comes out clear. Any remaining oil inside the tool will properly lubricate the tool.

7.Remember to replace the oil port screw when lubrication is completed.

NOTES:

This lubrication procedure will help reduce moisture, dust and dirt that gradually increases inside the impact wrench during use and reduces performance levels.

TROUBLESHOOTINGG GUIDEGUIDE

SYMPTOM | POSSIBLE CAUSE(S) | CORRECTIVE ACTION |

|

|

|

Tool will not run or runs | Grit in tool; tool gummed up | Clean the air motor inside the tool with |

slowly |

| (see “user maintenance” section). |

| No oil in tool | Add |

|

| tool (see “user maintenance” section). |

| Low air pressure | Adjust compressor regulator to 90 PSI. |

| Torque regulator at low setting. | Adjust torque regulator knob to a higher setting. |

| Air hose leaks | Tighten and seal hose fittings with Teflon® tape if |

|

| leaks are found. |

|

|

|

| TOOL SPECIFICATIONSTIONS |

Maximum Torque | 75 ft/lbs |

Average SCFM Requirements | 3.0 SCFM @ 90 PSI |

Air Inlet | 1/4” NPT (female) |

Square Drive | 3/8” |

Recommended Hose Size | 3/8” |

Maximum Working Pressure | 90 PSI |

5 - ENG