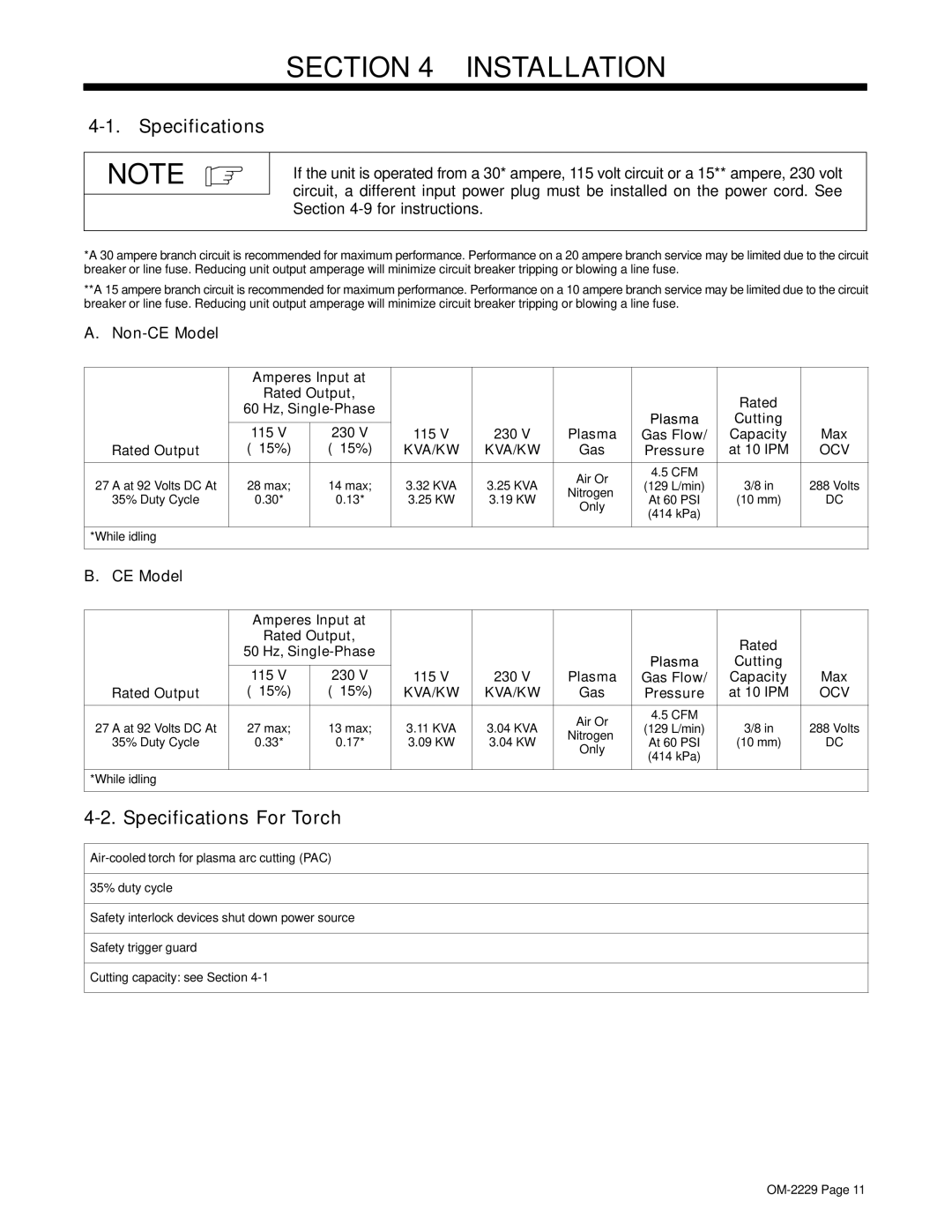

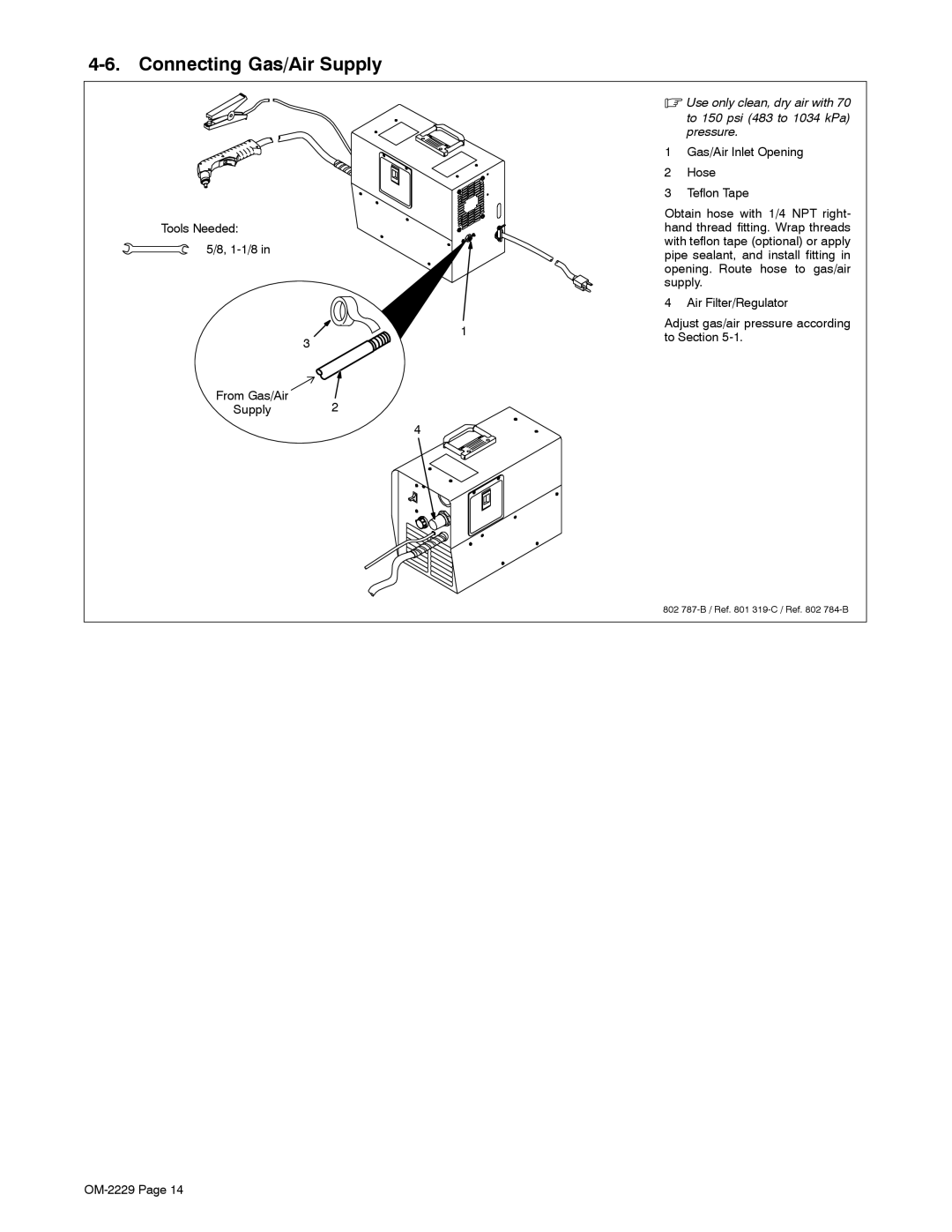

4-6. Connecting Gas/Air Supply

Tools Needed:

5/8,

1

3

From Gas/Air

Supply 2

4

.Use only clean, dry air with 70

to 150 psi (483 to 1034 kPa) pressure.

1Gas/Air Inlet Opening

2Hose

3Teflon Tape

Obtain hose with 1/4 NPT right- hand thread fitting. Wrap threads with teflon tape (optional) or apply pipe sealant, and install fitting in opening. Route hose to gas/air supply.

4 Air Filter/Regulator

Adjust gas/air pressure according to Section

802