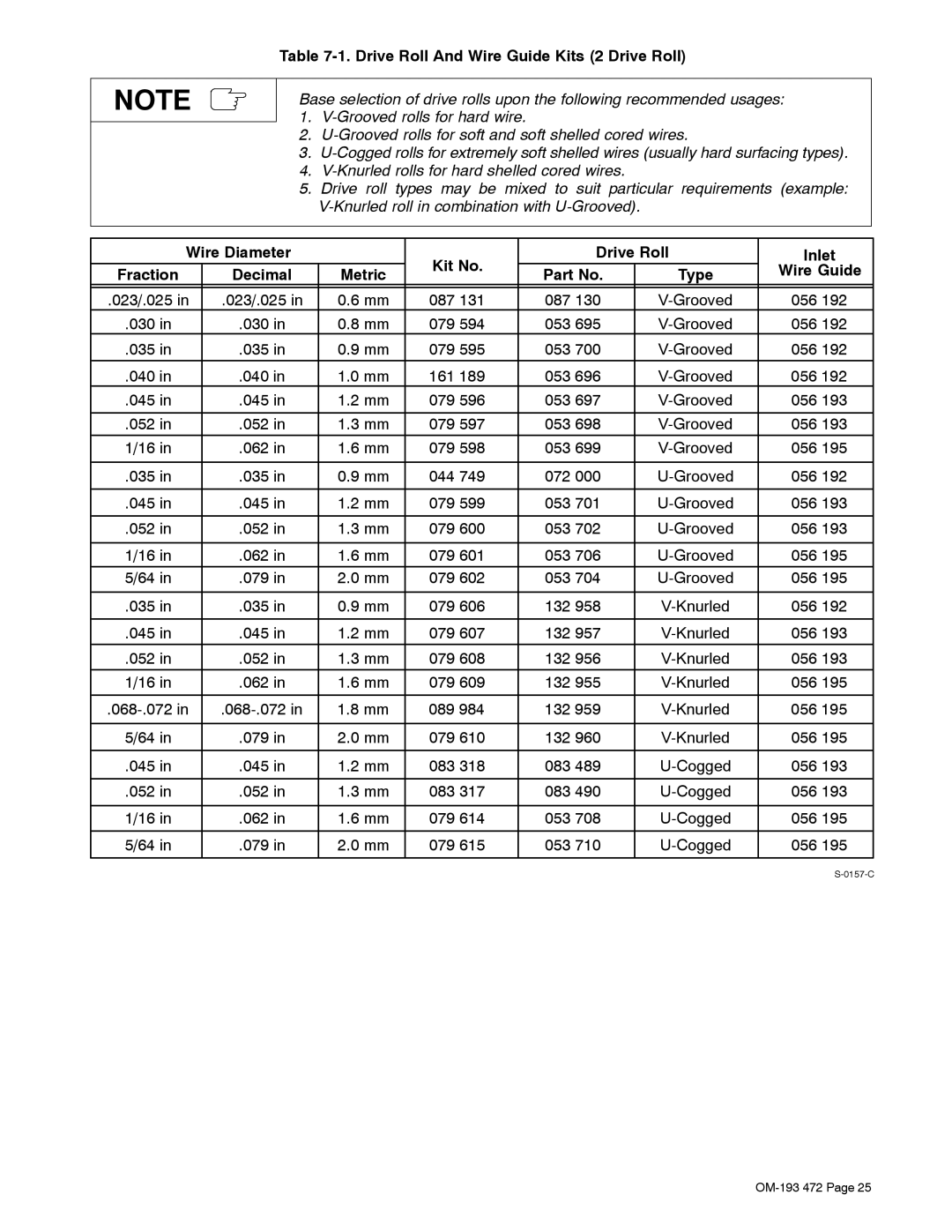

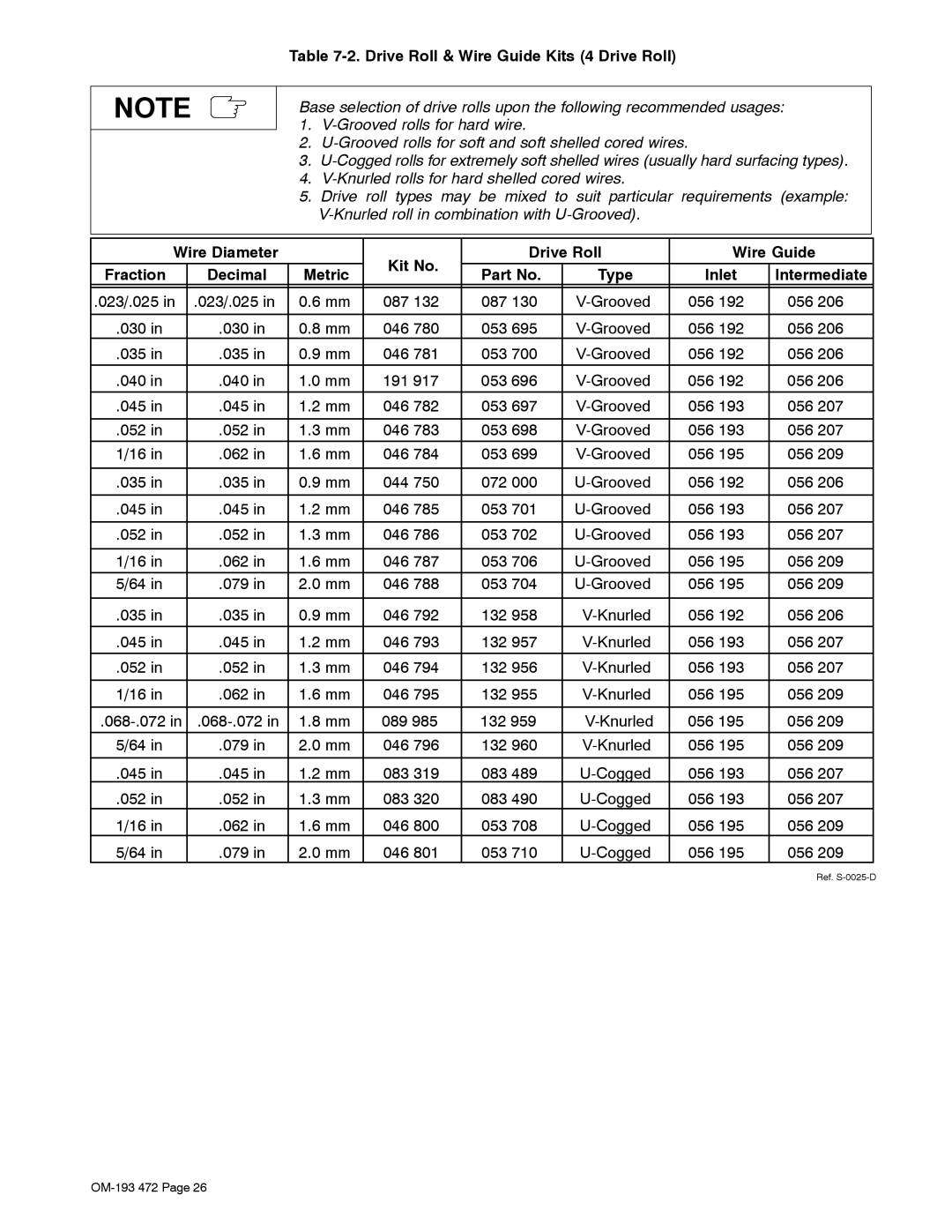

Table 7-2. Drive Roll & Wire Guide Kits (4 Drive Roll)

NOTE

Base selection of drive rolls upon the following recommended usages:

1.

2.

3.

4.

5.Drive roll types may be mixed to suit particular requirements (example:

Wire Diameter |

| Kit No. | Drive Roll | Wire Guide | ||||

Fraction | Decimal | Metric | Part No. | Type | Inlet | Intermediate | ||

| ||||||||

|

|

|

|

|

|

|

| |

.023/.025 in | .023/.025 in | 0.6 mm | 087 132 | 087 130 | 056 192 | 056 206 | ||

|

|

|

|

|

|

|

| |

.030 in | .030 in | 0.8 mm | 046 780 | 053 695 | 056 192 | 056 206 | ||

.035 in | .035 in | 0.9 mm | 046 781 | 053 700 | 056 192 | 056 206 | ||

.040 in | .040 in | 1.0 mm | 191 917 | 053 696 | 056 192 | 056 206 | ||

.045 in | .045 in | 1.2 mm | 046 782 | 053 697 | 056 193 | 056 207 | ||

|

|

|

|

|

|

|

| |

.052 in | .052 in | 1.3 mm | 046 783 | 053 698 | 056 193 | 056 207 | ||

1/16 in | .062 in | 1.6 mm | 046 784 | 053 699 | 056 195 | 056 209 | ||

|

|

|

|

|

|

|

| |

.035 in | .035 in | 0.9 mm | 044 750 | 072 000 | 056 192 | 056 206 | ||

|

|

|

|

|

|

|

| |

.045 in | .045 in | 1.2 mm | 046 785 | 053 701 | 056 193 | 056 207 | ||

|

|

|

|

|

|

|

| |

.052 in | .052 in | 1.3 mm | 046 786 | 053 702 | 056 193 | 056 207 | ||

|

|

|

|

|

|

|

| |

1/16 in | .062 in | 1.6 mm | 046 787 | 053 706 | 056 195 | 056 209 | ||

5/64 in | .079 in | 2.0 mm | 046 788 | 053 704 | 056 195 | 056 209 | ||

|

|

|

|

|

|

|

| |

.035 in | .035 in | 0.9 mm | 046 792 | 132 958 | 056 192 | 056 206 | ||

.045 in | .045 in | 1.2 mm | 046 793 | 132 957 | 056 193 | 056 207 | ||

.052 in | .052 in | 1.3 mm | 046 794 | 132 956 | 056 193 | 056 207 | ||

|

|

|

|

|

|

|

| |

1/16 in | .062 in | 1.6 mm | 046 795 | 132 955 | 056 195 | 056 209 | ||

|

|

|

|

|

|

|

| |

1.8 mm | 089 985 | 132 959 | 056 195 | 056 209 | ||||

5/64 in | .079 in | 2.0 mm | 046 796 | 132 960 | 056 195 | 056 209 | ||

|

|

|

|

|

|

|

| |

.045 in | .045 in | 1.2 mm | 083 319 | 083 489 | 056 193 | 056 207 | ||

.052 in | .052 in | 1.3 mm | 083 320 | 083 490 | 056 193 | 056 207 | ||

1/16 in | .062 in | 1.6 mm | 046 800 | 053 708 | 056 195 | 056 209 | ||

5/64 in | .079 in | 2.0 mm | 046 801 | 053 710 | 056 195 | 056 209 | ||

Ref.