•The fire must always be confined within the boundaries of the fuel grate.

•The fireplace screens must always be closed whenever the fireplace is being used.

•Never slam the glass door since it could cause the glass to break.

•Do not build excessively large or hot fires — scorching or discoloring of the plated brass trim may occur.

•Extreme temperature changes can cause glass breakage — do not build a hot fire and close the glass doors if the doors are cold.

•If the tempered glass pane becomes scratched or chipped, it creates a weakness in the glass which can cause the glass to break when heated. Replace the pane of glass by contact- ing your nearest dealer.

CAUTION: GLASS AND METAL FRAMES GET HOT — ALWAYS USE HANDLES TO OPEN AND CLOSE THE DOORS.

WARNING: BE AWARE THAT SAFETY GLASS IS UNPREDICTABLE WHEN HOT AND MAY BREAK, EXPELLING HOT GLASS INTO THE ROOM. ADVISE ALL FAMILY MEMBERS TO REMAIN WELL AWAY FROM THE FIREPLACE WHEN OPERAT- ING WITH DOORS CLOSED TO AVOID ANY POSSIBLE PERSONAL INJURY.

IMPORTANT: Plated polished brass glass doors may have a plastic covering over all brass pieces for protection during shipping and handling. The plastic covering should be removed before installation of the glass doors. Under the plastic covering is a protective lacquer coating which should not be removed. In some instances, if it is removed, irrevers- ible damage to the brass finish could occur. Refer to the following for specific information on plated polished brass.

IMPORTANT: The lacquer coating on the pol- ished brass glass doors and trim pieces can be damaged or removed causing corrosion and/or tarnish. Do not remove the protective lacquer coating from plated polished doors and trim. To help protect the finish; use a non-acidic wax and avoid the over-spray of acidic/alkali based glass cleaners on the brass pieces. Please understand that the heat of the fire will cause the protective lacquer finish to slightly change to a light caramel color. Do not be alarmed as this is a normal occurrence.

COMBUSTION AIR

A proper amount of combustion air is important for your fireplace. Fireplaces consume large amounts of oxygen. It is important to allow an adequate supply of air.

If the fireplace is not equipped with an outside air kit, it may not obtain sufficient amounts of combustion air from inside the house or struc- ture in which it is installed. Therefore, the fire may draw from an outside air source and pull air in through the chimney. This may cause smoke spillage into the room.

Smoke spillage often occurs when a fire is first started, until the fireplace and the chimney has had the opportunity to “come up to tempera- ture” and to begin to function normally. If smoke spillage problems persist, a window may be opened just a crack to allow the proper flow of combustion air to the fireplace.

If your fireplace is equipped with an outside combustion air kit, keep it open at all times when fire is burning and close when fire is out to prevent cold air intrusion.

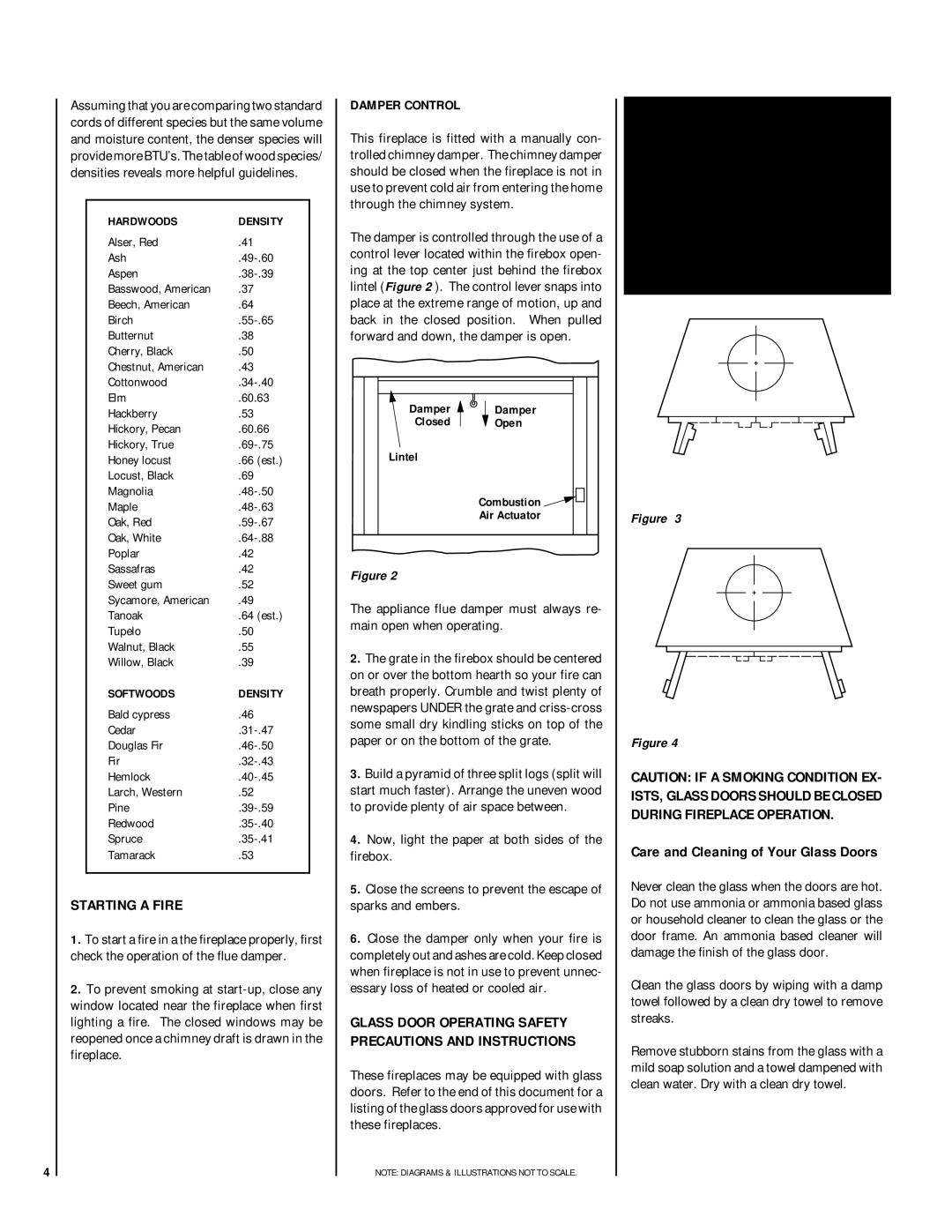

Combustion Air Control

The actuator for combustion air system is standard on all fireplaces but must not be operated if the complete system is not in- stalled. See Figure 5 and refer to Figure 2.

If you have reason to believe that you do not have a complete outside combustion system, contact your distributor to have your fireplace inspected for the presence of the complete system before you use the combustion air actuator. DO NOT assume that you have this system in place because you have an actuating lever present on your fireplace front face.

WARNING: DO NOT OPERATE THE COM- BUSTION AIR ACTUATOR UNLESS A COMPLETE OUTSIDE COMBUSTION AIR VENT SYSTEM HAS BEEN INSTALLED WITH YOUR FIREPLACE.

To provide outside combustion air to your fireplace while it is in operation, locate the combustion air actuator along the right side of the fireplace opening behind the screen.

To operate, push the end of the actuator to the left as shown in Figure 5, until it "pops" free of its "locked" position. Pull the actuator forward to open the combustion air door, and push it back to close.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

To "lock" the combustion air door closed, ensure the actuator is pushed all the way back, then push the end of the actuators to the right until the step in the actuator moves behind the fireplace front face within the slotted opening.

Combustion Air

Actuator

Pull Forward to Open,

Push Back to Close

Figure 5

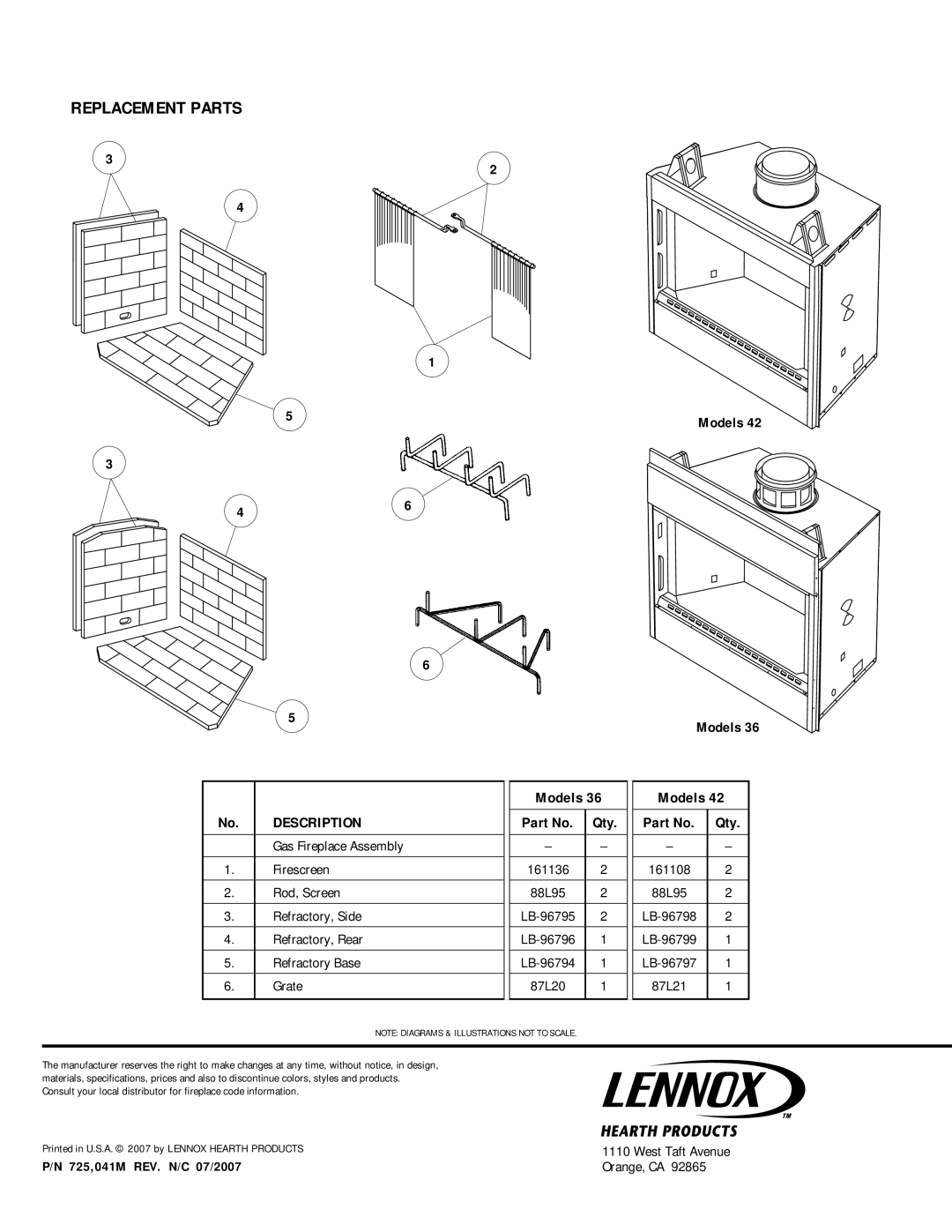

REFRACTORIES

All fireboxes contain a furnace refractory floor, sides and back. These refractories are rein- forced with steel, but can be broken by improper use. Dropping logs on the bottom refractory and building fires directly against the refracto- ries can cause premature burnout of these components. It may easily be repaired or re- placed at costs far below repair and maintenance for masonry fireplaces.

Proper care and “burn-in” of the firebox will prolong the period of enjoyment without exten- sive maintenance. For the first few uses, build small fires – not roaring infernos. The materials used in the refractories contain and absorb mois- ture. It is important to “cure” the refractories by building only modest fires. Under normal usage, it is expected that hairline cracks will appear in the refractory surface. These hairline cracks do not affect the safe operation of the fireplace.

Refractories should be replaced when:

1.The crack opens more than ¹⁄₄" (19 mm).

2.Pitting in the surface is extensive and pits become deeper than ³⁄₁₆" (4.76 mm).

3.Any piece of refractory larger than 2" (51 mm) in radius and ³⁄₁₆" deep becomes dislodged.

If conditions 1, 2 or 3 occur, the refractory should be replaced.

5