Troubleshooting, Adjustment & Service

SUSPENSION ADJUSTMENT

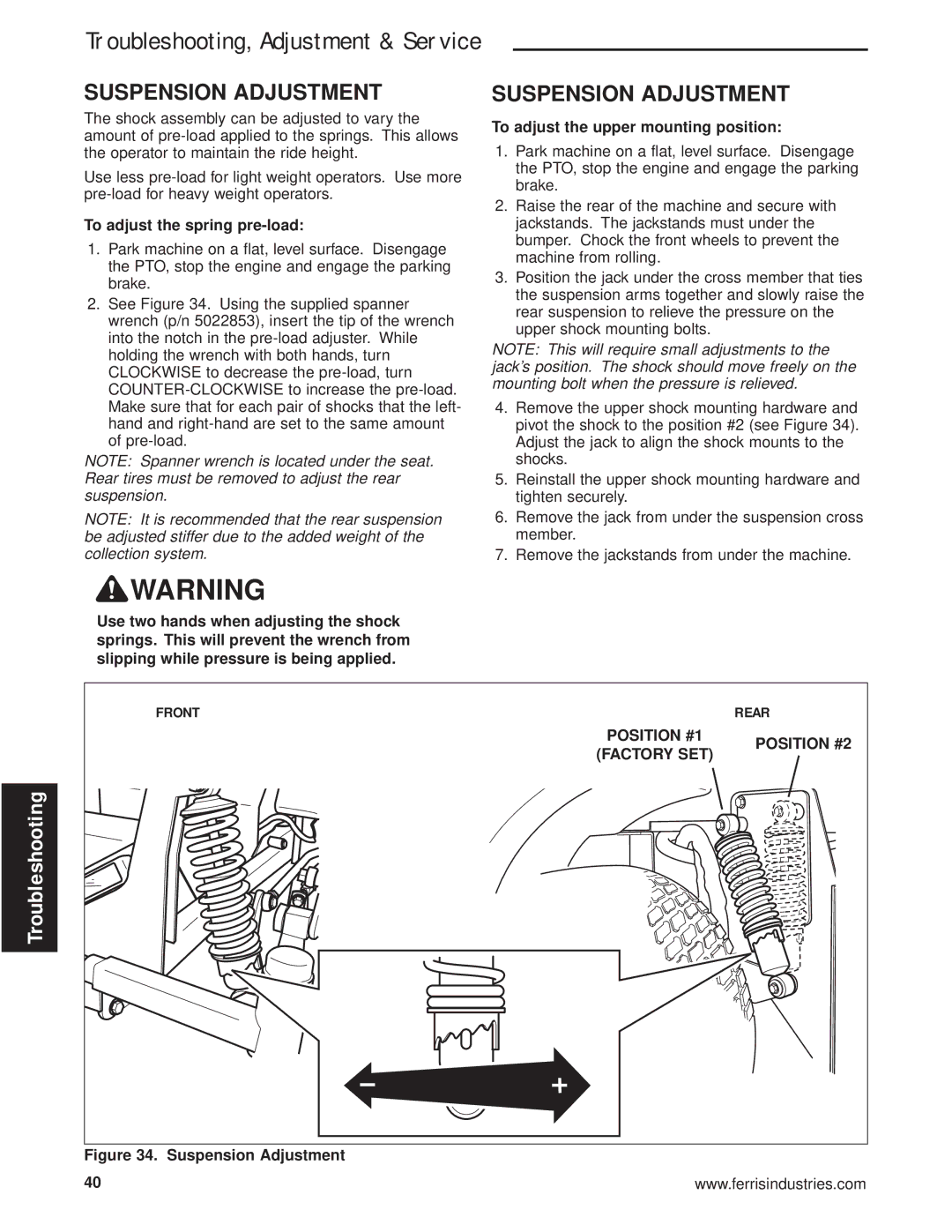

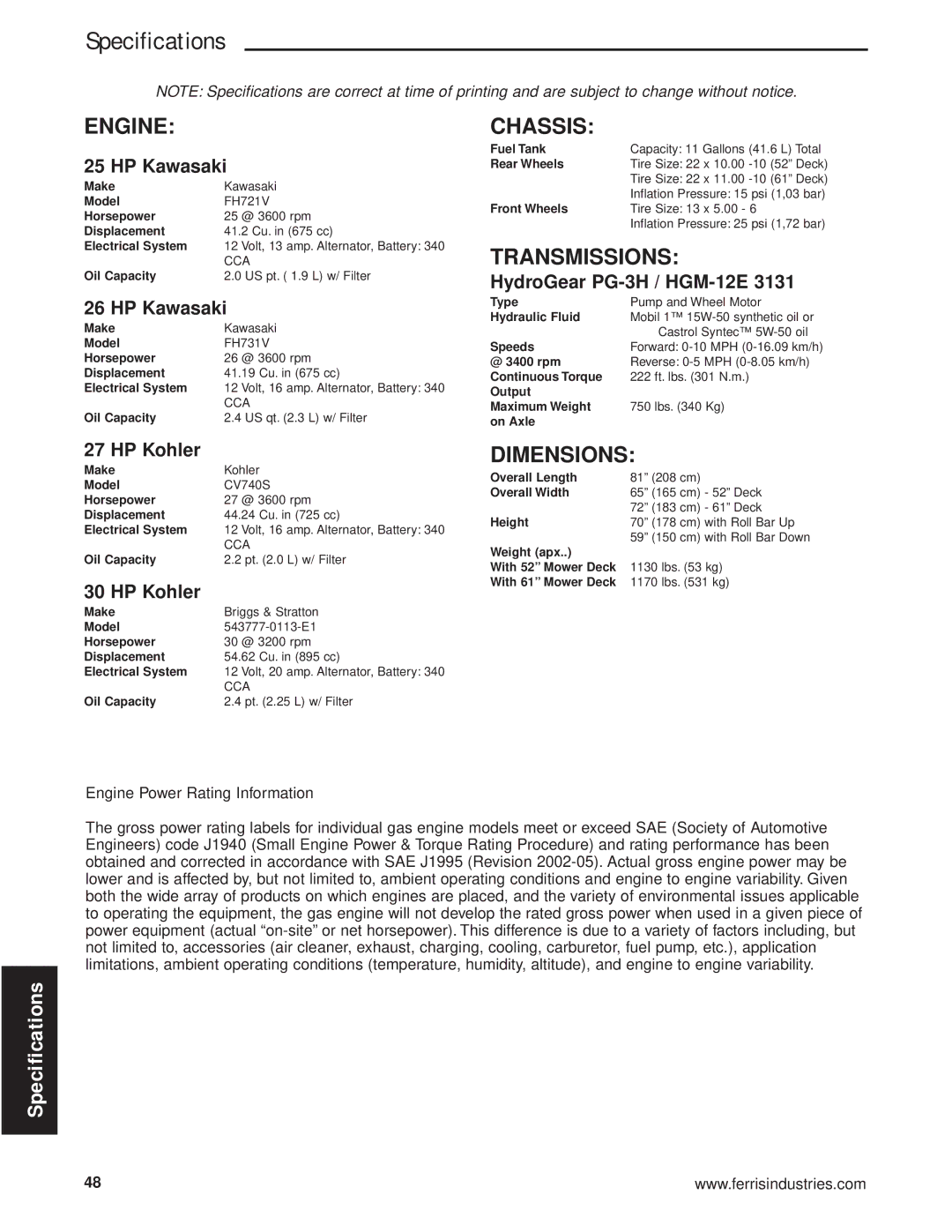

The shock assembly can be adjusted to vary the amount of

Use less

To adjust the spring pre-load:

1.Park machine on a flat, level surface. Disengage the PTO, stop the engine and engage the parking brake.

2.See Figure 34. Using the supplied spanner wrench (p/n 5022853), insert the tip of the wrench into the notch in the

NOTE: Spanner wrench is located under the seat. Rear tires must be removed to adjust the rear suspension.

NOTE: It is recommended that the rear suspension be adjusted stiffer due to the added weight of the collection system.

SUSPENSION ADJUSTMENT

To adjust the upper mounting position:

1.Park machine on a flat, level surface. Disengage the PTO, stop the engine and engage the parking brake.

2.Raise the rear of the machine and secure with jackstands. The jackstands must under the bumper. Chock the front wheels to prevent the machine from rolling.

3.Position the jack under the cross member that ties the suspension arms together and slowly raise the rear suspension to relieve the pressure on the upper shock mounting bolts.

NOTE: This will require small adjustments to the jack’s position. The shock should move freely on the mounting bolt when the pressure is relieved.

4.Remove the upper shock mounting hardware and pivot the shock to the position #2 (see Figure 34). Adjust the jack to align the shock mounts to the shocks.

5.Reinstall the upper shock mounting hardware and tighten securely.

6.Remove the jack from under the suspension cross member.

7.Remove the jackstands from under the machine.

![]() WARNING

WARNING

Use two hands when adjusting the shock springs. This will prevent the wrench from slipping while pressure is being applied.

FRONT |

| REAR |

| POSITION #1 | POSITION #2 |

| (FACTORY SET) | |

|

| |

Troubleshooting |

|

|

Figure 34. Suspension Adjustment

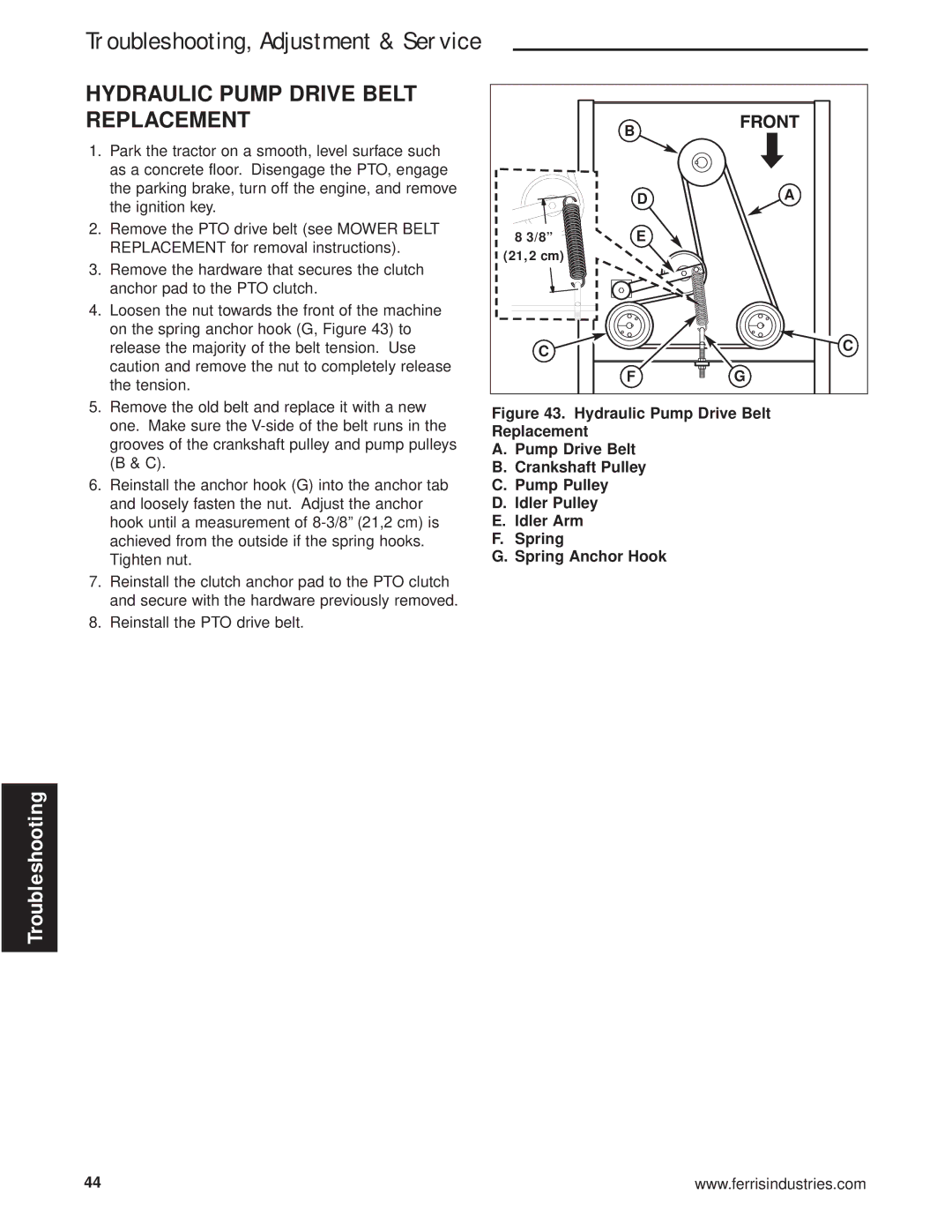

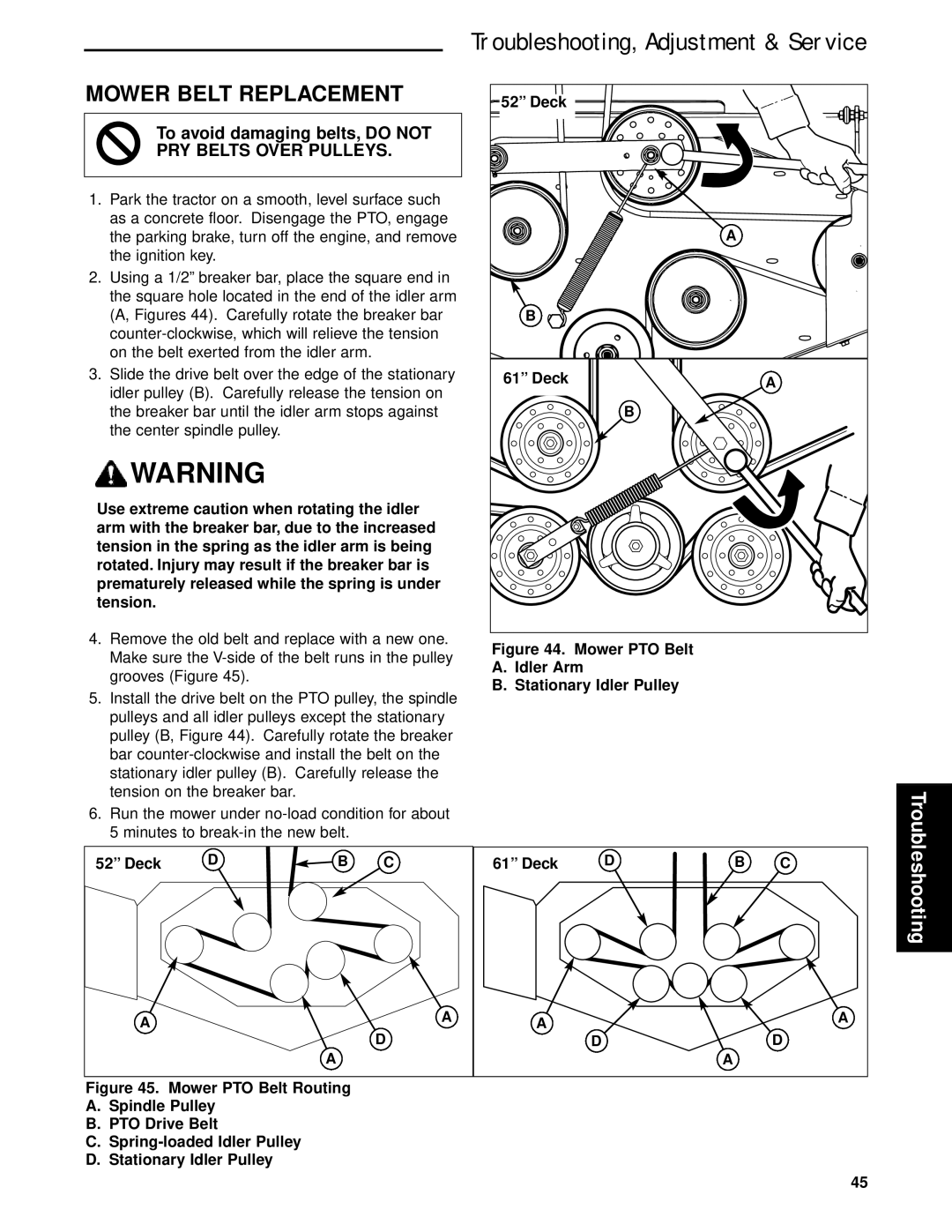

40 | www.ferrisindustries.com |