6

Trouble

Shooting

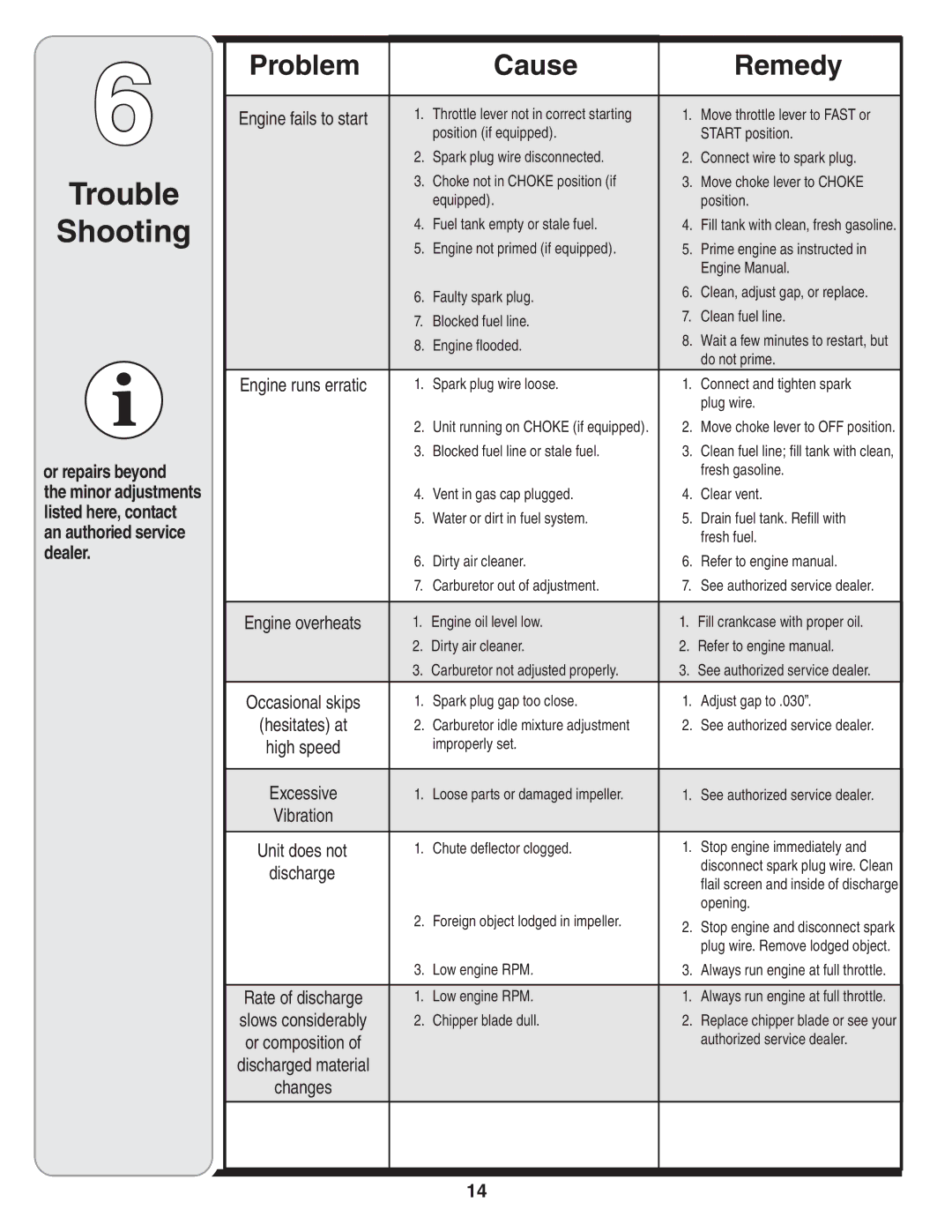

For repairs beyond the minor adjustments listed here, contact an authorized service dealer.

Problem |

| Cause |

| Remedy |

|

|

|

|

|

Engine fails to start | 1. | Throttle lever not in correct starting | 1. | Move throttle lever to FAST or |

|

| position (if equipped). |

| START position. |

| 2. | Spark plug wire disconnected. | 2. | Connect wire to spark plug. |

| 3. | Choke not in CHOKE position (if | 3. | Move choke lever to CHOKE |

|

| equipped). |

| position. |

| 4. | Fuel tank empty or stale fuel. | 4. | Fill tank with clean, fresh gasoline. |

| 5. | Engine not primed (if equipped). | 5. | Prime engine as instructed in |

|

|

|

| Engine Manual. |

| 6. | Faulty spark plug. | 6. | Clean, adjust gap, or replace. |

|

|

| ||

| 7. | Blocked fuel line. | 7. | Clean fuel line. |

|

|

| ||

| 8. | Engine flooded. | 8. | Wait a few minutes to restart, but |

|

| do not prime. | ||

|

|

|

| |

Engine runs erratic | 1. | Spark plug wire loose. | 1. | Connect and tighten spark |

|

|

|

| plug wire. |

| 2. | Unit running on CHOKE (if equipped). | 2. | Move choke lever to OFF position. |

| 3. | Blocked fuel line or stale fuel. | 3. | Clean fuel line; fill tank with clean, |

|

|

|

| fresh gasoline. |

| 4. | Vent in gas cap plugged. | 4. | Clear vent. |

| 5. | Water or dirt in fuel system. | 5. | Drain fuel tank. Refill with |

|

|

|

| fresh fuel. |

| 6. | Dirty air cleaner. | 6. | Refer to engine manual. |

| 7. | Carburetor out of adjustment. | 7. | See authorized service dealer. |

|

|

|

|

|

Engine overheats | 1. | Engine oil level low. | 1. | Fill crankcase with proper oil. |

| 2. | Dirty air cleaner. | 2. | Refer to engine manual. |

| 3. | Carburetor not adjusted properly. | 3. | See authorized service dealer. |

Occasional skips | 1. | Spark plug gap too close. | 1. | Adjust gap to .030”. |

(hesitates) at | 2. | Carburetor idle mixture adjustment | 2. | See authorized service dealer. |

high speed |

| improperly set. |

|

|

|

|

|

|

|

Excessive | 1. | Loose parts or damaged impeller. | 1. | See authorized service dealer. |

Vibration |

|

|

|

|

|

|

|

|

|

Unit does not | 1. | Chute deflector clogged. | 1. | Stop engine immediately and |

discharge |

|

|

| disconnect spark plug wire. Clean |

|

|

| flail screen and inside of discharge | |

|

|

|

| |

|

|

|

| opening. |

| 2. | Foreign object lodged in impeller. | 2. | Stop engine and disconnect spark |

|

|

| ||

|

|

|

| plug wire. Remove lodged object. |

| 3. | Low engine RPM. | 3. | Always run engine at full throttle. |

|

|

|

|

|

Rate of discharge | 1. | Low engine RPM. | 1. | Always run engine at full throttle. |

slows considerably | 2. | Chipper blade dull. | 2. | Replace chipper blade or see your |

or composition of |

|

|

| authorized service dealer. |

discharged material |

|

|

|

|

changes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14