The condensate trap may be primed by filling the CONDENSATE U-ASSEMBLY with tap water while the water heater is not operating. The system is fully primed when the water level reaches the adaptor connected into the Tee. In most installations the water heater will self-prime the condensate trap during the first full heat-up cycle. If a sound of air bubbling through water (gurgling) is heard while the blower is operating after the first heat-up cycle, then turn the unit off and contact your plumber or service representative.

If these instructions are not followed, the condensate build-up will block the exhaust outlet, which will cause improper operation.

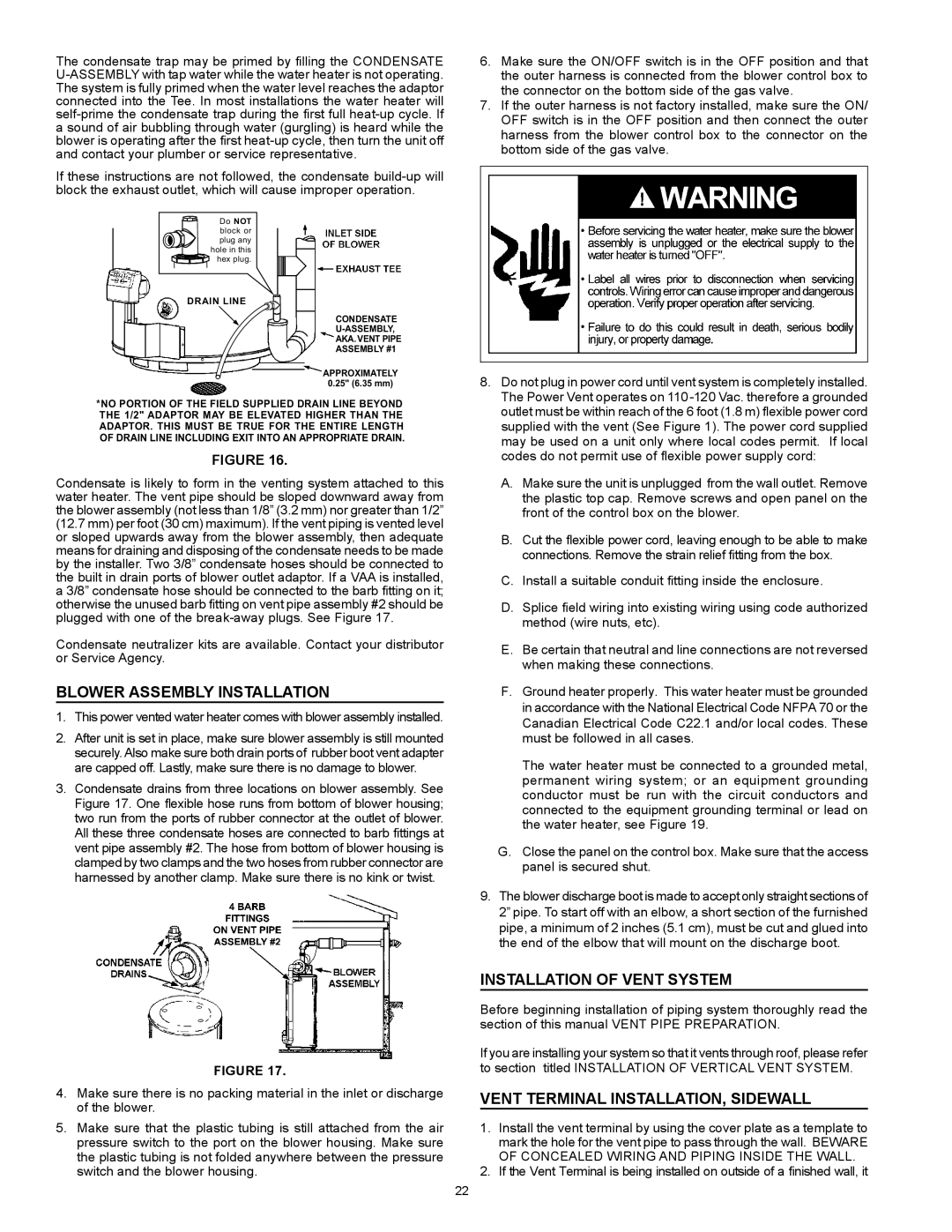

Do NOT block or plug any hole in this hex plug.

DRAIN LINE

CONDENSATE

U-ASSEMBLY,

AKA. VENT PIPE

ASSEMBLY #1

APPROXIMATELY

0.25" (6.35 mm)

*NO PORTION OF THE FIELD SUPPLIED DRAIN LINE BEYOND THE 1/2" ADAPTOR MAY BE ELEVATED HIGHER THAN THE ADAPTOR. THIS MUST BE TRUE FOR THE ENTIRE LENGTH OF DRAIN LINE INCLUDING EXIT INTO AN APPROPRIATE DRAIN.

FIGURE 16.

Condensate is likely to form in the venting system attached to this water heater. The vent pipe should be sloped downward away from the blower assembly (not less than 1/8” (3.2 mm) nor greater than 1/2” (12.7 mm) per foot (30 cm) maximum). If the vent piping is vented level or sloped upwards away from the blower assembly, then adequate means for draining and disposing of the condensate needs to be made by the installer. Two 3/8” condensate hoses should be connected to the built in drain ports of blower outlet adaptor. If a VAA is installed, a 3/8” condensate hose should be connected to the barb fitting on it; otherwise the unused barb fitting on vent pipe assembly #2 should be plugged with one of the break-away plugs. See Figure 17.

Condensate neutralizer kits are available. Contact your distributor or Service Agency.

BLOWER ASSEMBLY INSTALLATION

1.This power vented water heater comes with blower assembly installed.

2.After unit is set in place, make sure blower assembly is still mounted securely.Also make sure both drain ports of rubber boot vent adapter are capped off. Lastly, make sure there is no damage to blower.

3.Condensate drains from three locations on blower assembly. See

Figure 17. One flexible hose runs from bottom of blower housing; two run from the ports of rubber connector at the outlet of blower.

All these three condensate hoses are connected to barb fittings at vent pipe assembly #2. The hose from bottom of blower housing is clamped by two clamps and the two hoses from rubber connector are harnessed by another clamp. Make sure there is no kink or twist.

FIGURE 17.

4.Make sure there is no packing material in the inlet or discharge of the blower.

5.Make sure that the plastic tubing is still attached from the air pressure switch to the port on the blower housing. Make sure the plastic tubing is not folded anywhere between the pressure switch and the blower housing.

6.Make sure the ON/OFF switch is in the OFF position and that the outer harness is connected from the blower control box to the connector on the bottom side of the gas valve.

7.If the outer harness is not factory installed, make sure the ON/ OFF switch is in the OFF position and then connect the outer harness from the blower control box to the connector on the bottom side of the gas valve.

8.Do not plug in power cord until vent system is completely installed. The Power Vent operates on 110-120 Vac. therefore a grounded outlet must be within reach of the 6 foot (1.8 m) flexible power cord supplied with the vent (See Figure 1). The power cord supplied may be used on a unit only where local codes permit. If local codes do not permit use of flexible power supply cord:

A.Make sure the unit is unplugged from the wall outlet. Remove the plastic top cap. Remove screws and open panel on the front of the control box on the blower.

B.Cut the flexible power cord, leaving enough to be able to make connections. Remove the strain relief fitting from the box.

C.Install a suitable conduit fitting inside the enclosure.

D.Splice field wiring into existing wiring using code authorized method (wire nuts, etc).

E.Be certain that neutral and line connections are not reversed when making these connections.

F.Ground heater properly. This water heater must be grounded in accordance with the National Electrical Code NFPA 70 or the Canadian Electrical Code C22.1 and/or local codes. These must be followed in all cases.

The water heater must be connected to a grounded metal, permanent wiring system; or an equipment grounding conductor must be run with the circuit conductors and connected to the equipment grounding terminal or lead on the water heater, see Figure 19.

G.Close the panel on the control box. Make sure that the access panel is secured shut.

9.The blower discharge boot is made to accept only straight sections of 2” pipe. To start off with an elbow, a short section of the furnished pipe, a minimum of 2 inches (5.1 cm), must be cut and glued into the end of the elbow that will mount on the discharge boot.

INSTALLATION OF VENT SYSTEM

Before beginning installation of piping system thoroughly read the section of this manual VENT PIPE PREPARATION.

If you are installing your system so that it vents through roof, please refer to section titled INSTALLATION OF VERTICAL VENT SYSTEM.

VENT TERMINAL INSTALLATION, SIDEWALL

1.Install the vent terminal by using the cover plate as a template to mark the hole for the vent pipe to pass through the wall. BEWARE OF CONCEALED WIRING AND PIPING INSIDE THE WALL.

2.If the Vent Terminal is being installed on outside of a finished wall, it