Data Label

When contacting ADC, certain information is required to ensure proper service/parts information. This information is on the data label, located on the top right corner of the dryer, viewed from the rear (refer to illustration). When contacting ADC, please have the model number and serial number readily accessible.

Information on the Data Label

A.Model number — The model number is an ADC number which describes the size of the dryer and the type of heat (gas or steam).

B.Serial number — The serial number allows ADC to gather information on your particular dryer.

C.Manufacturing code number — The manufacturing code number is a number issued by ADC, which describes all possible options on your particular model.

D.Type of heat — Describes the type of heat; gas (natural or L.P.), steam or electric.

E.Heat input — (For gas dryers) describes the heat input in British Thermal Units.

F.Electric service — Describes the electric service for your particular models.

G.Gas manifold pressure — Describe the manifold pressure as taken at the gas valve pressure tap (refer to “Using a Manometer”).

Using a Manometer

How To Use A Manometer

With dryer in

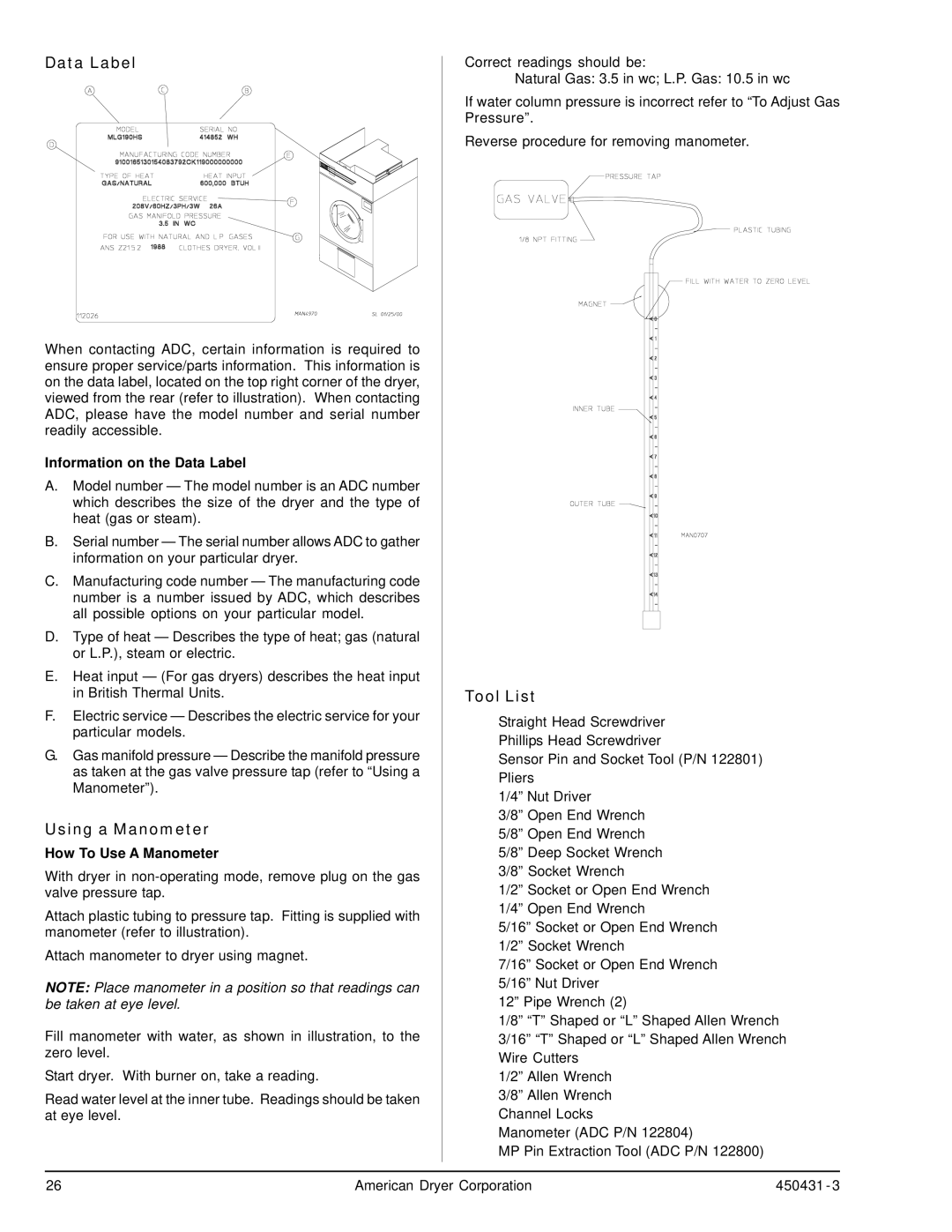

Attach plastic tubing to pressure tap. Fitting is supplied with manometer (refer to illustration).

Attach manometer to dryer using magnet.

NOTE: Place manometer in a position so that readings can be taken at eye level.

Fill manometer with water, as shown in illustration, to the zero level.

Start dryer. With burner on, take a reading.

Read water level at the inner tube. Readings should be taken at eye level.

Correct readings should be:

Natural Gas: 3.5 in wc; L.P. Gas: 10.5 in wc

If water column pressure is incorrect refer to “To Adjust Gas Pressure”.

Reverse procedure for removing manometer.

Tool List

Straight Head Screwdriver

Phillips Head Screwdriver

Sensor Pin and Socket Tool (P/N 122801) Pliers

1/4” Nut Driver

3/8” Open End Wrench

5/8” Open End Wrench 5/8” Deep Socket Wrench 3/8” Socket Wrench

1/2” Socket or Open End Wrench 1/4” Open End Wrench

5/16” Socket or Open End Wrench 1/2” Socket Wrench

7/16” Socket or Open End Wrench 5/16” Nut Driver

12” Pipe Wrench (2)

1/8” “T” Shaped or “L” Shaped Allen Wrench 3/16” “T” Shaped or “L” Shaped Allen Wrench Wire Cutters

1/2” Allen Wrench

3/8” Allen Wrench Channel Locks

Manometer (ADC P/N 122804)

MP Pin Extraction Tool (ADC P/N 122800)

26 | American Dryer Corporation | 450431 - 3 |