MAINTENANCE

MAINTENANCE

Maintenance Instructions

Before operating the mower, make sure it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricate and maintain this machine to provide long life and trouble free operation.

Check all bolt tightness BEFORE initial operation of the mower. Retorque all hardware after the first 4 hours of operation. A torque chart is provided at the end of the maintenance section.

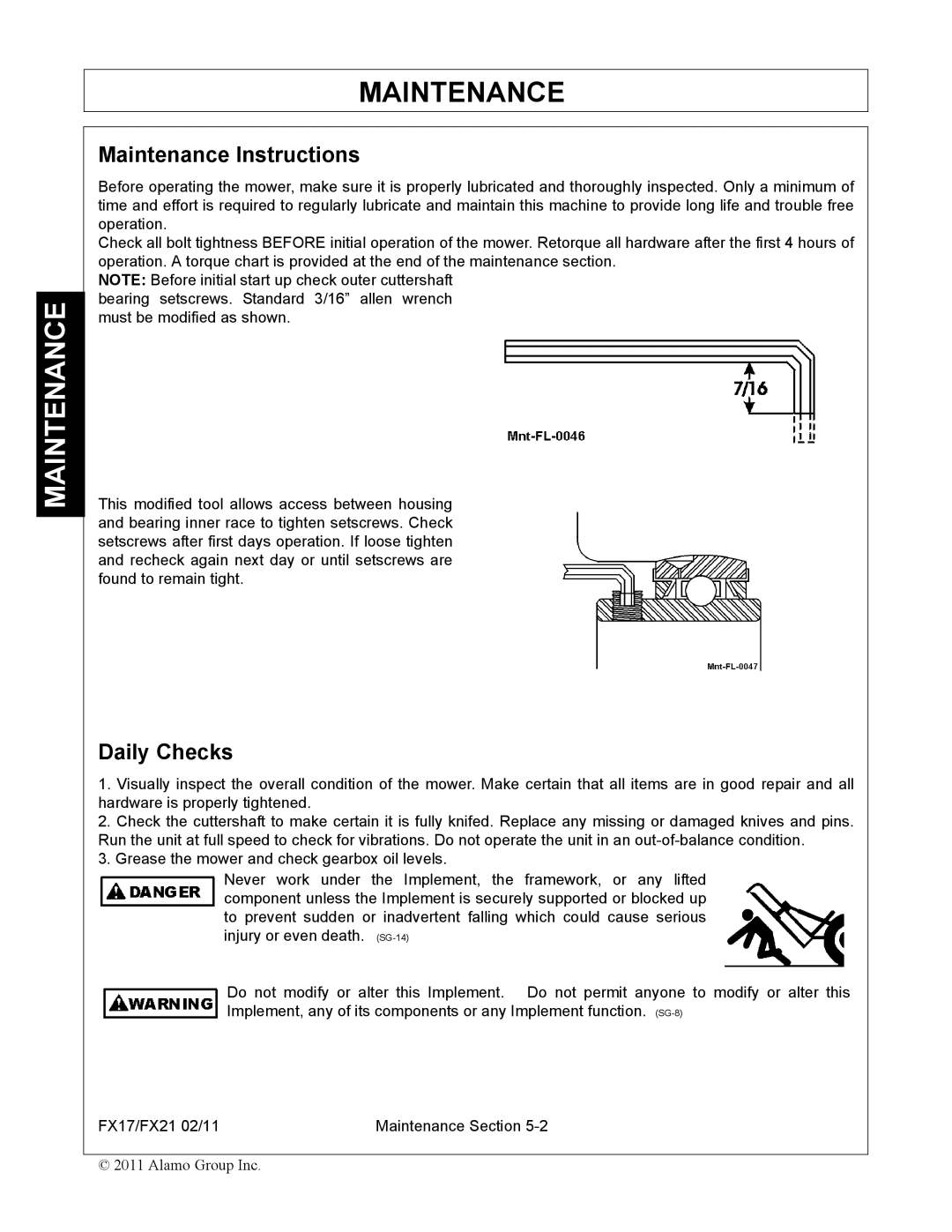

NOTE: Before initial start up check outer cuttershaft bearing setscrews. Standard 3/16” allen wrench must be modified as shown.

This modified tool allows access between housing and bearing inner race to tighten setscrews. Check setscrews after first days operation. If loose tighten and recheck again next day or until setscrews are found to remain tight.

Daily Checks

1.Visually inspect the overall condition of the mower. Make certain that all items are in good repair and all hardware is properly tightened.

2.Check the cuttershaft to make certain it is fully knifed. Replace any missing or damaged knives and pins. Run the unit at full speed to check for vibrations. Do not operate the unit in an

3.Grease the mower and check gearbox oil levels.

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to prevent sudden or inadvertent falling which could cause serious injury or even death.

Do not modify or alter this Implement. Do not permit anyone to modify or alter this Implement, any of its components or any Implement function.

FX17/FX21 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.