MAINTENANCE

Sharpening

These Alloy Knives can be sharpened by filing or grinding. If by grinding, keep cool to maintain hardness and avoid early dulling. When sharpening, remove metal mostly at the end of the tip and not much next to the shank. This will make the cutting portion taper rather than long and weak after several sharpenings. If the Rhino Electric Grinder is used, the knives can be sharpened without removing from the machine. Sharp knives require less power than dull knives. Sharp knives do a better job than dull knives. Replace broken or missing knives promptly!

Straightening

These Alloy Spring Steel Knives are tough and will bend quite far before they break, and can be straightened several times if bent slightly from hitting obstructions. Use two pairs of pliers or EavesdropsTM or Special tools. Replace any broken or cracked blade at once to prevent the knife’s flying off causing imbalance and vibration or possible serious bodily injury.

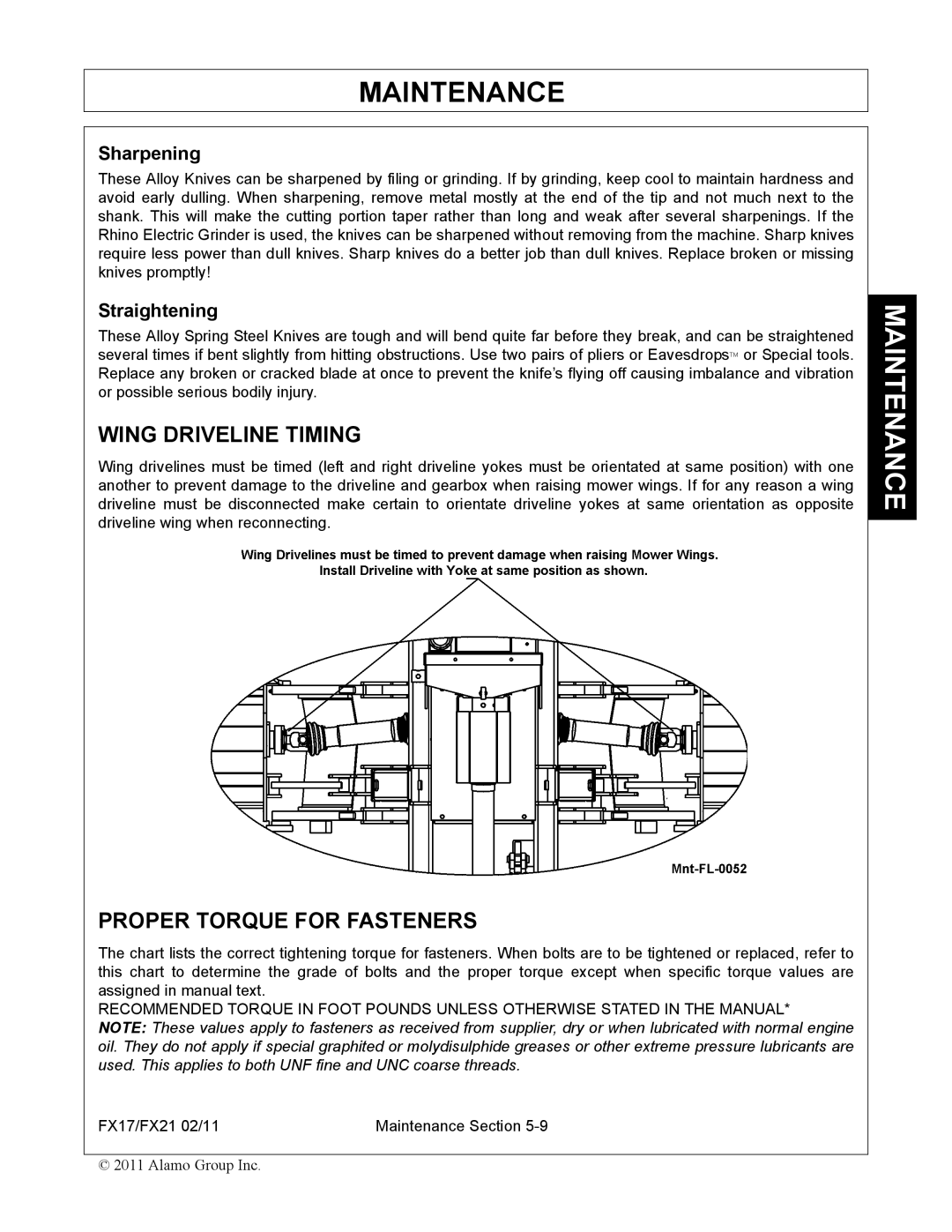

WING DRIVELINE TIMING

Wing drivelines must be timed (left and right driveline yokes must be orientated at same position) with one another to prevent damage to the driveline and gearbox when raising mower wings. If for any reason a wing driveline must be disconnected make certain to orientate driveline yokes at same orientation as opposite driveline wing when reconnecting.

PROPER TORQUE FOR FASTENERS

The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this chart to determine the grade of bolts and the proper torque except when specific torque values are assigned in manual text.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL*

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads.

FX17/FX21 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.