Exhaust reauirements

Fire Hazard

l Do Not use

10.2 cm (4 In) In diameter.

lDo Not use exhaust hoods with magnetic latches.

l Check that exhaust system Is not longer than speclfled. Exhaust systems longer than speclfled will:

-Accumulate Ilnt.

-Shorten the II18of the product.

-Reduce performance and result In longer drying times and Increased energy usage.

Failure to follow speclflcatlons may result In a flre.

lDo Not exhaust the dryer Into a chimney, furnace cold alr duct, attlc or

crawl space, or any other duct used for venting.

lClean the exhaust system every other

year.

lDo Not Install flexible duct under wall, celling or rloor materials.

Accumulated lint could be fuel for a flre or cause moisture damage.

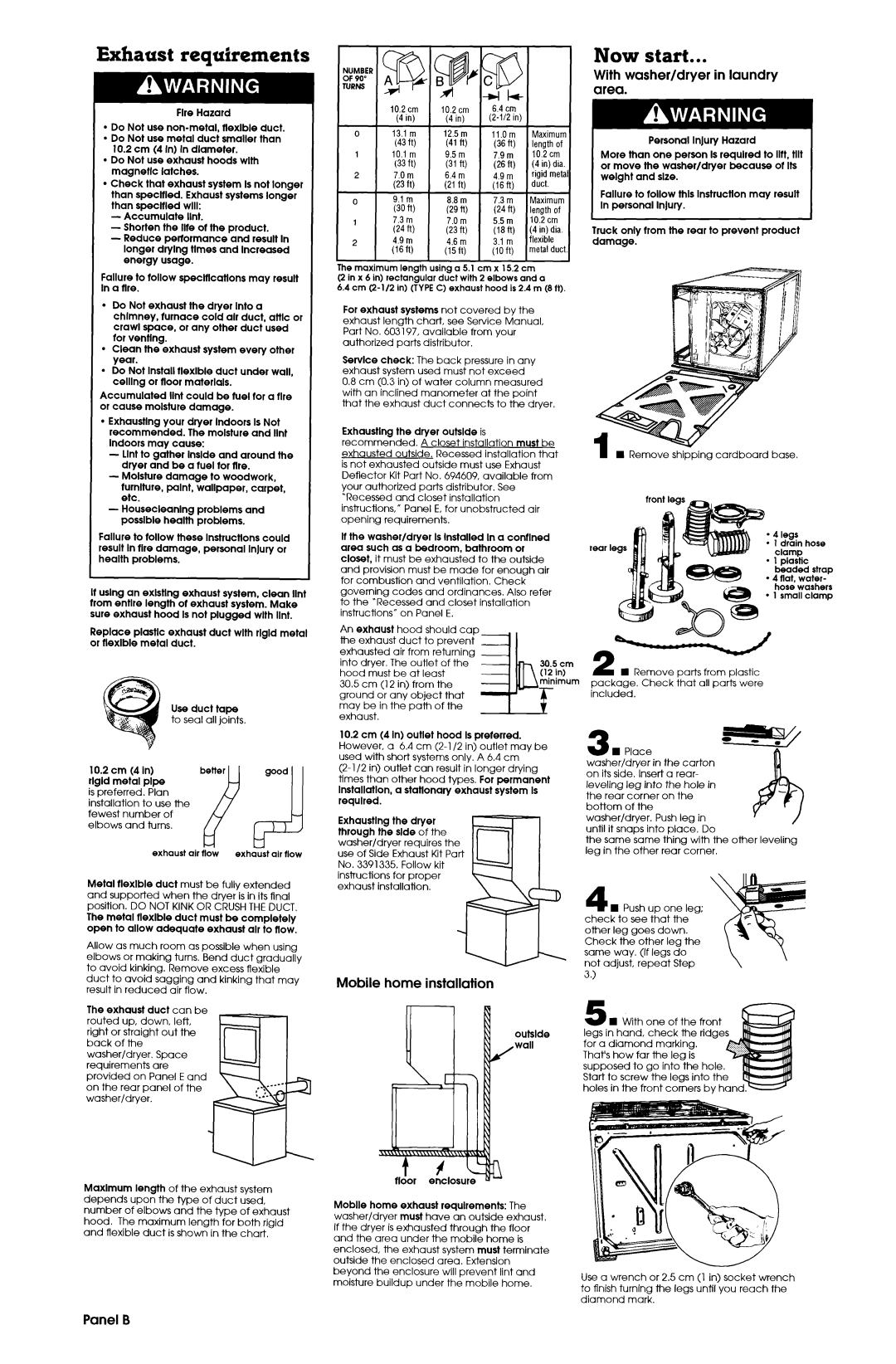

NUMBER

OF 90”

TURNS

10.2cm (4 in)

13.1 m | 12.5 m | 11.0 m | Maximum | |

(43 ft) | (41 fu | I (36 ft) | length of | |

10.1 m | 9.5 m | 7.9 m | 10.2 cm | |

(33 ft) | (31 fv | (26fi) | (4 in) dia. | |

7.0 | m | 6.4 m | 4.9 m | rigid meta |

(23 | ft) | (21 ft) | (16ft) | duct. |

9.1 m |

|

| engthof | |

(30 w |

|

| ||

7.3 m | 7.0 m | 5.5 m | 10.2 cm | |

(24 | ft) | (23 fi) | U8fQ | 4 in) dia. |

4.9 m | 4.6 m | 3.1 m | lexible | |

Wfi) | (lsft) | (10 ft) | netalduct | |

The maximum length using a 5.1 cm x 15.2 cm (2 in x 6 in) rectangular duct with 2 elbows and a

6.4 cm

For exhaust systems not covered by the exhaust length chart, see Service Manual, Part No. 603197, available from your authorized parts distributor.

Service check: The back pressure in any exhaust system used must not exceed

0.8cm (0.3 in) of water column measured with an inclined manometer at the point that the exhaust duct connects to the dryer.

Now start...

With washer/dryer in laundry area.

Personal Injury Hazard

More than one person Is required to Ilft, tilt or move the washer/dryer because of Its weight and size.

Failure to follow this InstructIon may result In personal Injury.

Truck only from the rear to prevent product damage.

l Exhausting your dryer Indoors Is Not recommended. The moisture and lint Indoors may cause:

-Lint to gather lnslde and around the dryer and be a fuel for rlre.

-Moisture damage to woodwork, furniture, paint, wallpaper, carpet, etc.

-Housecleanlng problems and posslble health problems.

Failure to follow these lnstructlons could result In fire damage, personal InJury or health problems.

If uslng an exlstlng exhaust system, clean lint from entlre length of exhaust system. Make sure exhaust hood Is not plugged with Ilnt.

Replace plastic exhaust duct with rlgld metal or tlexlble metal duct.

Use duct tape |

to seal all joints. |

Exhausting the dryer outslde is

recommended. A closet installation must be exhausted outside. Recessed installation that is not exhausted outside must use Exhaust Deflector Kit Part No. 694609, available from your authorized parts distributor. See “Recessed and closet installation instructions,” Panel E. for unobstructed air opening requirements.

If the washer/dryer Is Installed In a conflned area such as a bedroom, bathroom or closet, it must be exhausted to the outside and provision must be made for enough air for combustion and ventilation. Check governing codes and ordinances. Also refer to the “Recessed and closet installation instructions” on Panel E.

An exhaust hood should cap |

|

| ||||

the exhaust duct to prevent |

|

| ||||

exhausted | air | from | returning |

|

| |

into | dryer. | The | outlet | of the | 30.5 | cm |

hood | must | be | at least | (12 | in) | |

30.5 cm (12 in) from the | minimum | |

| ||

ground or any object that |

| |

may be in the path of the | 3% | |

exhaust. | ||

|

n Remove shipping cardboard base.

l 4 legs

l 1 drain hose clamp

l 1plastic beaded strap

l 4 flat, water- hose washers

l 1 small clamp

n Remove parts from plastic package. Check that all parts were included.

10.2 cm (4 in) | better | good |

rlgld metal pipe |

|

|

is preferred. Plan installation to use the fewest number of elbows and turns.

&CA

exhaust air flow exhaust air flow

Metal rlexlble duct must be fully extended and supported when the dryer is in its final position. DO NOT KINK OR CRUSH THE DUCT.

The metal flexible duct must be completely open to allow adequate exhaust alr to flow.

Allow as much room as possible when using elbows or making turns. Bend duct gradually to avoid kinking. Remove excess flexible duct to avoid sagging and kinking that may result in reduced air flow.

The exhaust duct can be routed up, down, left, right or straight out the back of the washer/dryer. Space requirements are provided on Panel E and on the rear panel of the washer/dryer.

Maxlmum length of the exhaust system depends upon the type of duct used, number of elbows and the type of exhaust hood. The maximum length for both rigid and flexible duct is shown in the chart.

10.2cm (4 In) outlet hood Is preferred.

However, a 6.4 cm

Exhaustlng the dryer through the side of the

washer/dryer requires the use of Side Exhaust Kit Part No. 3391335. Follow kit instructions for proper exhaust installation.

Mobile home installation

outslde wall

I/

floor

Moblle home exhaust requirements: The washer/dryer must have an outside exhaust. If the dryer is exhausted through the floor and the area under the mobile home is enclosed, the exhaust system must terminate outside the enclosed area. Extension beyond the enclosure will prevent lint and moisture buildup under the mobile home.

washer/dryer in the carton on its side. Insert a rear- leveling leg into the hole in the rear corner on the bottom of the washer/dryer. Push leg in until it snaps into place. Do

the same same thing with the other leveling leg in the other rear corner.

4 n Push up one leg; check to see that the other leg goes down. Check the other leg the same way. (If legs do not adjust, repeat Step 3.1

nWith one of the front legs in hand, check the ridges

fo;a diamond marking. - That’s how far the leg is supposed to go into the hole. Start to screw the legs into the holes in the front corners by han

Jse a wrench or 2.5 cm (1 in) socket wrench !o finish turning the legs until you reach the diamond mark.