| | | 746-7-00 |

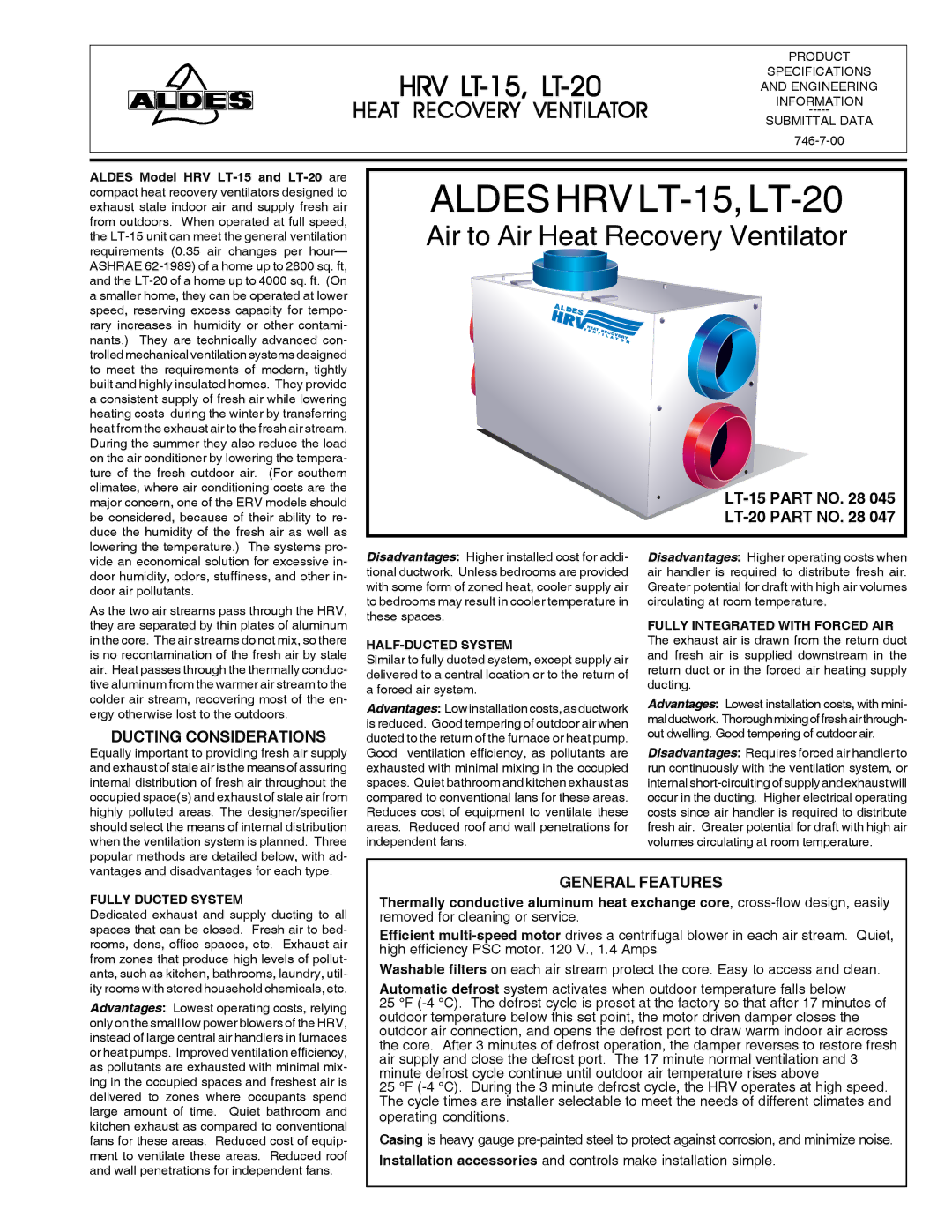

| ALDES Model HRV LT-15 and LT-20 are | ALDES HRV LT-15, LT-20 |

| exhaust stale indoor air and supply fresh air |

| compact heat recovery ventilators designed to | | |

| from outdoors. When operated at full speed, | Air to Air Heat Recovery Ventilator |

| the LT-15 unit can meet the general ventilation |

| | |

| requirements (0.35 air changes per hour— | | |

| ASHRAE 62-1989) of a home up to 2800 sq. ft, | | |

| and the LT-20 of a home up to 4000 sq. ft. (On | | |

| a smaller home, they can be operated at lower | | |

| speed, reserving excess capacity for tempo- | | |

| rary increases in humidity or other contami- | | |

| nants.) They are technically advanced con- | | |

| trolled mechanical ventilation systems designed | | |

| to meet the requirements of modern, tightly | | |

| built and highly insulated homes. They provide | | |

| a consistent supply of fresh air while lowering | | |

| heating costs during the winter by transferring | | |

| heat from the exhaust air to the fresh air stream. | | |

| During the summer they also reduce the load | | |

| on the air conditioner by lowering the tempera- | | |

| ture of the fresh outdoor air. (For southern | | |

| climates, where air conditioning costs are the | | LT-15 PART NO. 28 045 |

| major concern, one of the ERV models should | |

| be considered, because of their ability to re- | | LT-20 PART NO. 28 047 |

| duce the humidity of the fresh air as well as | | |

| lowering the temperature.) The systems pro- | Disadvantages: Higher installed cost for addi- | Disadvantages: Higher operating costs when |

| vide an economical solution for excessive in- |

| tional ductwork. Unless bedrooms are provided | air handler is required to distribute fresh air. |

| door humidity, odors, stuffiness, and other in- |

| with some form of zoned heat, cooler supply air | Greater potential for draft with high air volumes |

| door air pollutants. |

| to bedrooms may result in cooler temperature in | circulating at room temperature. |

| As the two air streams pass through the HRV, |

| these spaces. | |

| they are separated by thin plates of aluminum | FULLY INTEGRATED WITH FORCED AIR |

| |

| in the core. The air streams do not mix, so there | HALF-DUCTED SYSTEM | The exhaust air is drawn from the return duct |

| is no recontamination of the fresh air by stale | and fresh air is supplied downstream in the |

| Similar to fully ducted system, except supply air |

| air. Heat passes through the thermally conduc- | return duct or in the forced air heating supply |

| delivered to a central location or to the return of |

| tive aluminum from the warmer air stream to the | ducting. |

| a forced air system. |

| colder air stream, recovering most of the en- | Advantages: Lowest installation costs, with mini- |

| Advantages: Low installation costs, as ductwork |

| ergy otherwise lost to the outdoors. |

| malductwork. Thoroughmixingoffreshairthrough- |

| is reduced. Good tempering of outdoor air when |

| |

| DUCTING CONSIDERATIONS | out dwelling. Good tempering of outdoor air. |

| ducted to the return of the furnace or heat pump. |

| Equally important to providing fresh air supply | Good ventilation efficiency, as pollutants are | Disadvantages: Requires forced air handler to |

| and exhaust of stale air is the means of assuring | exhausted with minimal mixing in the occupied | run continuously with the ventilation system, or |

| internal distribution of fresh air throughout the | spaces. Quiet bathroom and kitchen exhaust as | internal short-circuiting of supply and exhaust will |

| occupied space(s) and exhaust of stale air from | compared to conventional fans for these areas. | occur in the ducting. Higher electrical operating |

| highly polluted areas. The designer/specifier | Reduces cost of equipment to ventilate these | costs since air handler is required to distribute |

| should select the means of internal distribution | areas. Reduced roof and wall penetrations for | fresh air. Greater potential for draft with high air |

| when the ventilation system is planned. Three | independent fans. | volumes circulating at room temperature. |

| popular methods are detailed below, with ad- | | |

| vantages and disadvantages for each type. | GENERAL FEATURES |

| |

| FULLY DUCTED SYSTEM | Thermally conductive aluminum heat exchange core, cross-flow design, easily |

| Dedicated exhaust and supply ducting to all | removed for cleaning or service. | |

| spaces that can be closed. Fresh air to bed- | Efficient multi-speed motor drives a centrifugal blower in each air stream. Quiet, |

| rooms, dens, office spaces, etc. Exhaust air |

| high efficiency PSC motor. 120 V., 1.4 Amps |

| from zones that produce high levels of pollut- |

| Washable filters on each air stream protect the core. Easy to access and clean. |

| ants, such as kitchen, bathrooms, laundry, util- |

| ity rooms with stored household chemicals, etc. | Automatic defrost system activates when outdoor temperature falls below |

| Advantages: Lowest operating costs, relying | 25 °F (-4 °C). The defrost cycle is preset at the factory so that after 17 minutes of |

| outdoor temperature below this set point, the motor driven damper closes the |

| only on the small low power blowers of the HRV, |

| outdoor air connection, and opens the defrost port to draw warm indoor air across |

| instead of large central air handlers in furnaces |

| the core. After 3 minutes of defrost operation, the damper reverses to restore fresh |

| or heat pumps. Improved ventilation efficiency, |

| air supply and close the defrost port. The 17 minute normal ventilation and 3 |

| as pollutants are exhausted with minimal mix- |

| minute defrost cycle continue until outdoor air temperature rises above |

| ing in the occupied spaces and freshest air is |

| 25 °F (-4 °C). During the 3 minute defrost cycle, the HRV operates at high speed. |

| delivered to zones where occupants spend |

| The cycle times are installer selectable to meet the needs of different climates and |

| large amount of time. Quiet bathroom and |

| operating conditions. | |

| kitchen exhaust as compared to conventional | |

| Casing is heavy gauge pre-painted steel to protect against corrosion, and minimize noise. |

| fans for these areas. Reduced cost of equip- |

| ment to ventilate these areas. Reduced roof | Installation accessories and controls make installation simple. |

| and wall penetrations for independent fans. |

| | |