ADH-120, ADH-75, ADH-170 specifications

American Dryer Corp is renowned for its high-quality commercial dryer machines, catering to the needs of various industries, particularly in laundromats, hospitality, and healthcare. Among their extensive lineup, the ADH-170, ADH-75, and ADH-120 stand out for their efficiency, durability, and innovative technology designed to enhance user experience and operational efficiency.The ADH-170 is a heavy-duty dryer known for its impressive capacity and rapid drying times. With a substantial drum size, it can accommodate large loads, making it ideal for high-traffic commercial environments. This model features advanced moisture sensing technology that automatically adjusts drying times based on the moisture content of the load, ensuring optimal performance while conserving energy. The durable construction and rust-resistant materials also mean that the ADH-170 is built to withstand the rigors of daily use.

The ADH-75 is designed for establishments that require a balance of capacity and efficiency. It offers a slightly smaller drum size compared to the ADH-170 but maintains robust performance characteristics. This model is equipped with an intuitive control panel that allows operators to select various drying cycles and settings, optimizing the dryer’s performance for different fabric types. The ADH-75 also incorporates energy-saving features, such as a cool-down cycle that helps prevent fabric from overheating, thus prolonging garment life.

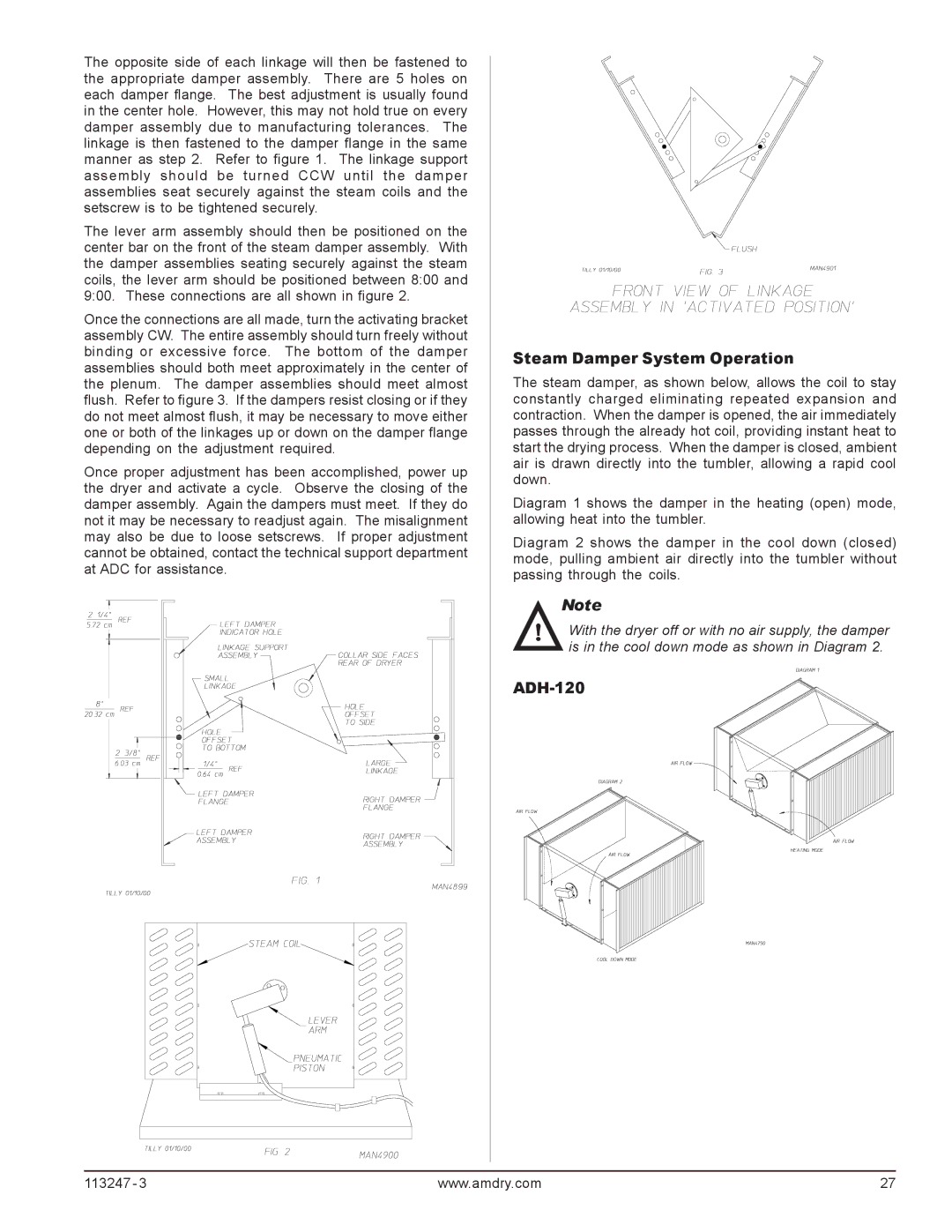

The ADH-120 is a versatile dryer that strikes an excellent balance between capacity and flexibility. This model comes with an innovative air-flow design, promoting quicker drying times and reducing energy consumption. Its ergonomic design ensures ease of use, while safety features protect operators and users alike. Furthermore, the ADH-120 is outfitted with user-friendly controls that provide programmable settings, making it suitable for various commercial applications.

Overall, the American Dryer Corp ADH series exemplifies a commitment to quality and performance in commercial laundry solutions. From the high-capacity ADH-170 to the efficient ADH-75 and the adaptable ADH-120, each model integrates advanced technology and robust design, making them reliable choices for businesses looking to optimize their laundry operations. With their user-friendly features and energy-efficient solutions, American Dryer Corp continues to set the standard in the commercial dryer market, ensuring customer satisfaction and operational excellence.