Pulling the belt through the tumbler felt gap will tend to flip the felt. Before pulling the last few inches out of the tumbler, lace the electrical wire back through the loop in the belt (Fig. 13 on the previous page).

Pull the remaining belt and a couple of inches of wire out of the tumbler and into the area above the tumbler. Slide the belt to the middle of the tumbler. With the electrical wire pulled tight (Fig. 14 on the previous page), rotate the tumbler one or two turns. This should flip the felt back to the original position. Feeling that the felt is even all the way around the tumbler indicates the felt is back to original position. Remove the electrical wire. The belt is now wrapped around the tumbler and ready for installation on the drive motor sheave.

PLACING THE BELT BACK ON THE MOTOR SHEAVE:

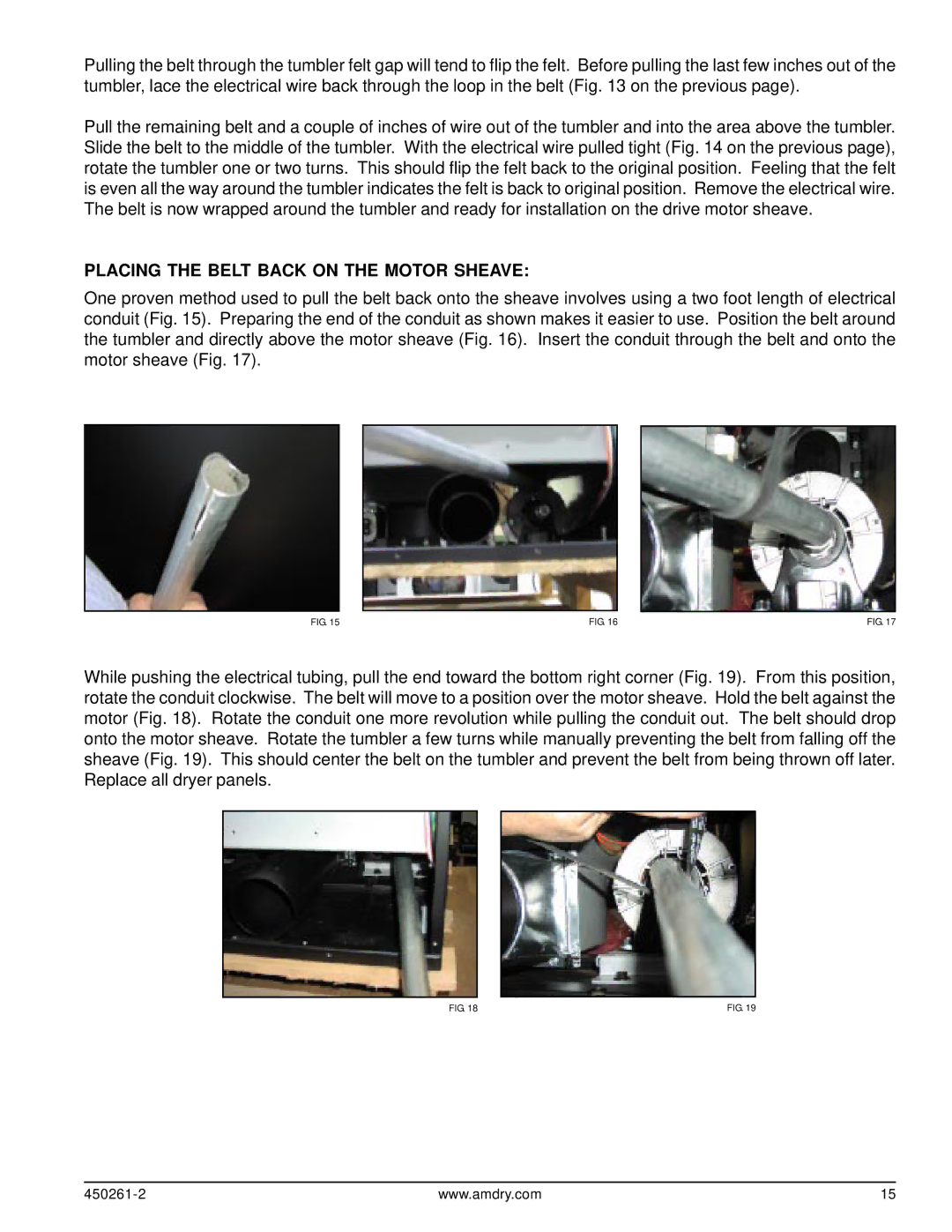

One proven method used to pull the belt back onto the sheave involves using a two foot length of electrical conduit (Fig. 15). Preparing the end of the conduit as shown makes it easier to use. Position the belt around the tumbler and directly above the motor sheave (Fig. 16). Insert the conduit through the belt and onto the motor sheave (Fig. 17).

FIG. 15 | FIG. 16 | FIG. 17 |

While pushing the electrical tubing, pull the end toward the bottom right corner (Fig. 19). From this position, rotate the conduit clockwise. The belt will move to a position over the motor sheave. Hold the belt against the motor (Fig. 18). Rotate the conduit one more revolution while pulling the conduit out. The belt should drop onto the motor sheave. Rotate the tumbler a few turns while manually preventing the belt from falling off the sheave (Fig. 19). This should center the belt on the tumbler and prevent the belt from being thrown off later. Replace all dryer panels.

FIG. 18 | FIG. 19 |

www.amdry.com | 15 |