IMPORTANT: Exhaust back pressure measured by a manometer at each basket (tumbler) exhaust duct area must be no less than 0 and must not exceed 0.3 inches (0.74 mb) of water column (W.C.).

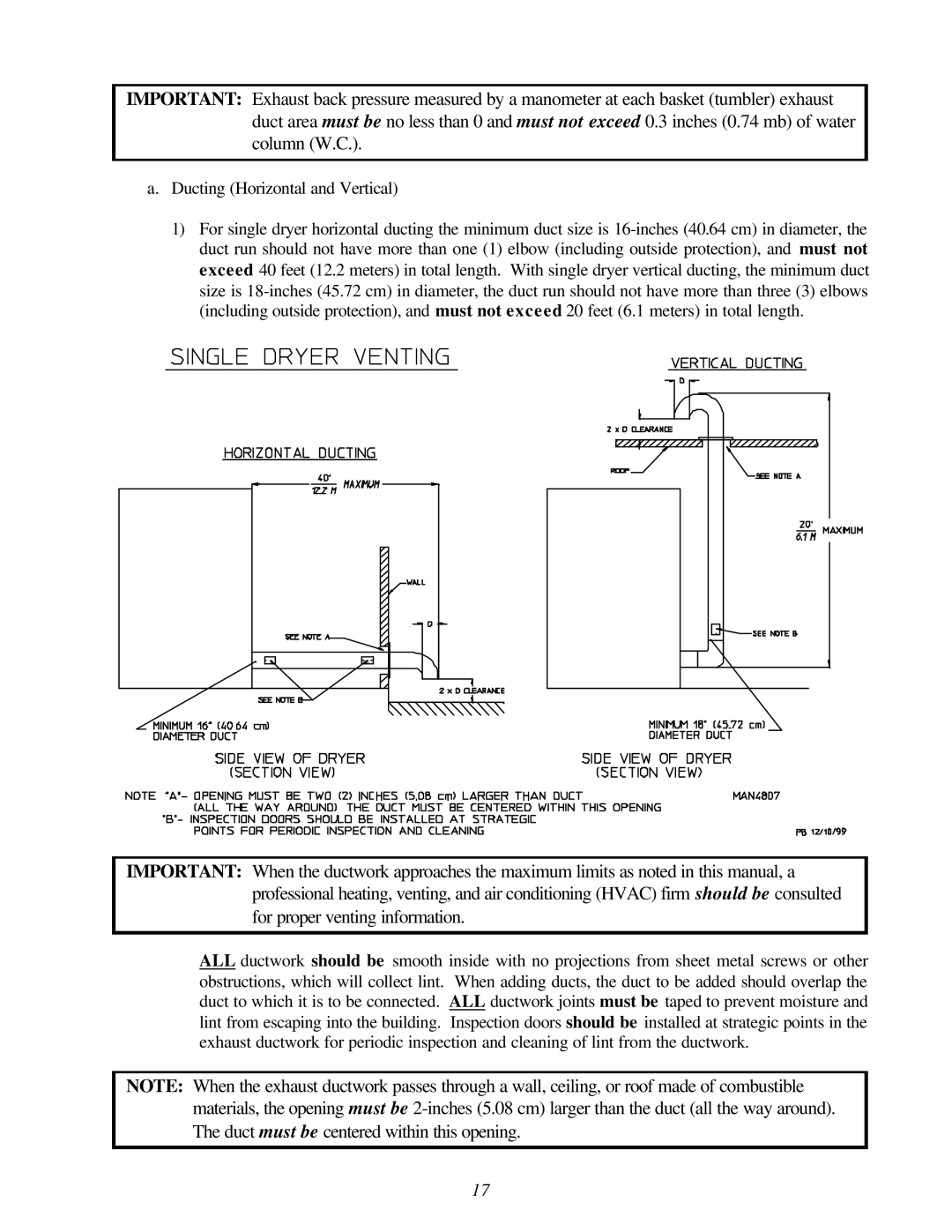

a.Ducting (Horizontal and Vertical)

1)For single dryer horizontal ducting the minimum duct size is

IMPORTANT: When the ductwork approaches the maximum limits as noted in this manual, a professional heating, venting, and air conditioning (HVAC) firm should be consulted for proper venting information.

ALL ductwork should be smooth inside with no projections from sheet metal screws or other obstructions, which will collect lint. When adding ducts, the duct to be added should overlap the duct to which it is to be connected. ALL ductwork joints must be taped to prevent moisture and lint from escaping into the building. Inspection doors should be installed at strategic points in the exhaust ductwork for periodic inspection and cleaning of lint from the ductwork.

NOTE: When the exhaust ductwork passes through a wall, ceiling, or roof made of combustible materials, the opening must be

17