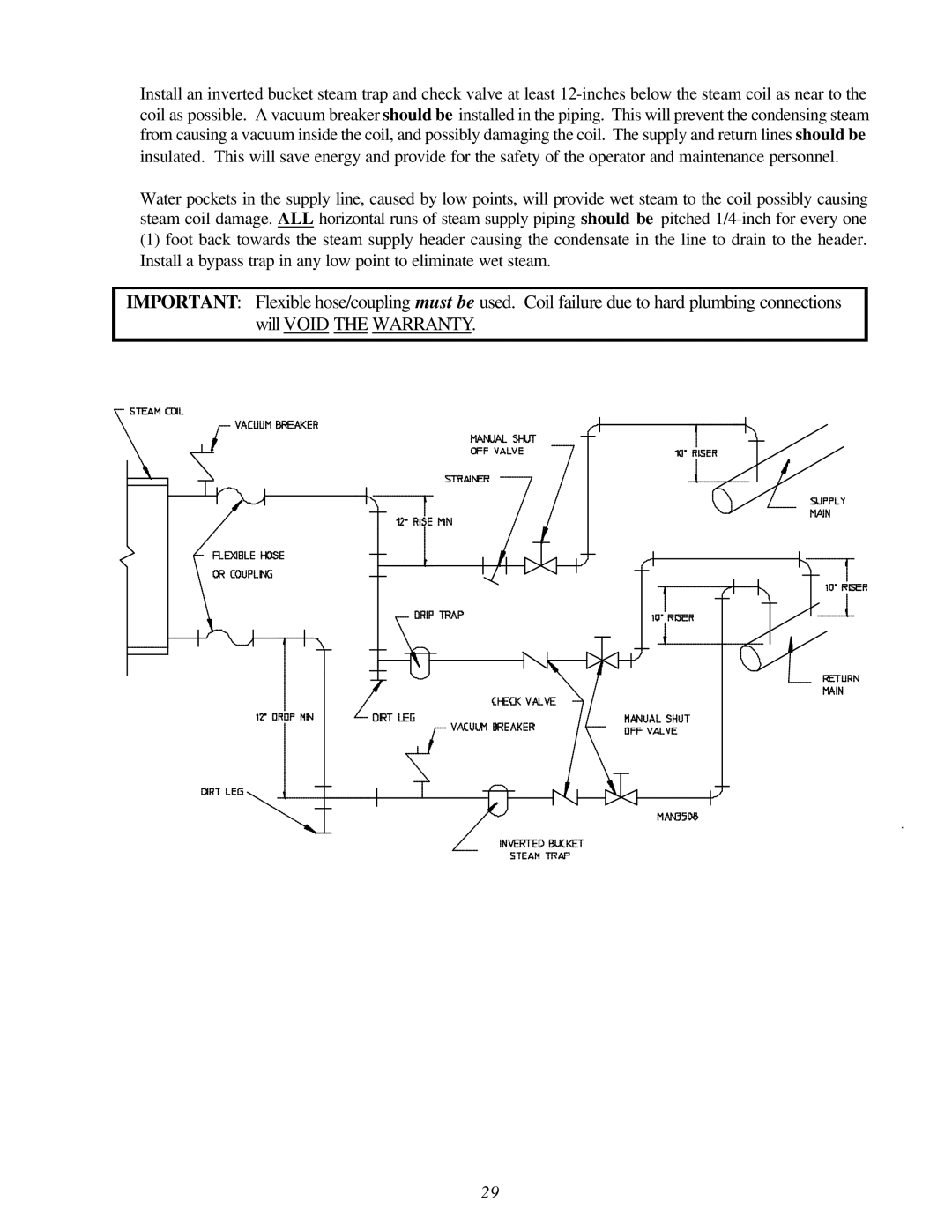

Install an inverted bucket steam trap and check valve at least

Water pockets in the supply line, caused by low points, will provide wet steam to the coil possibly causing steam coil damage. ALL horizontal runs of steam supply piping should be pitched

(1)foot back towards the steam supply header causing the condensate in the line to drain to the header. Install a bypass trap in any low point to eliminate wet steam.

IMPORTANT: Flexible hose/coupling must be used. Coil failure due to hard plumbing connections will VOID THE WARRANTY.

29