Electric Models Only

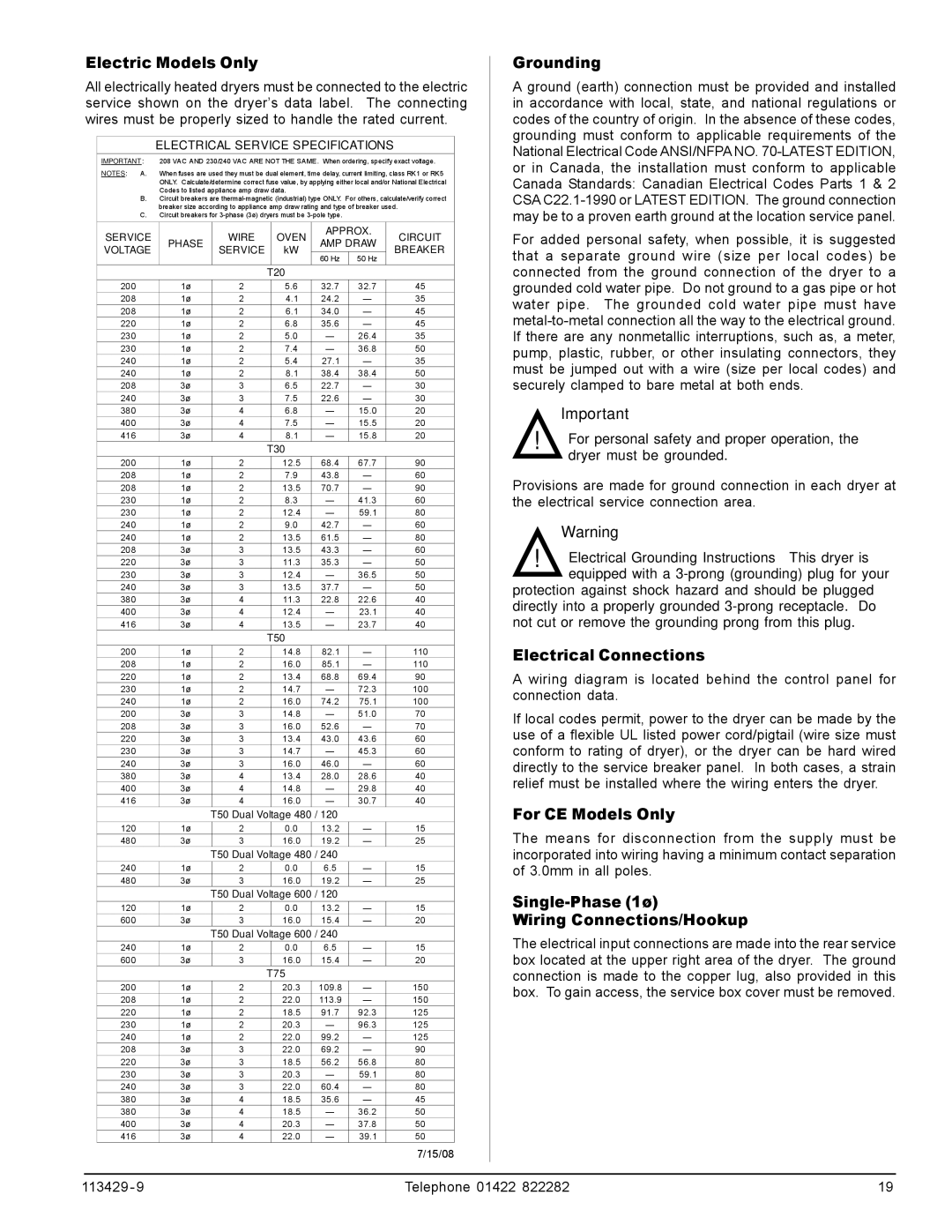

All electrically heated dryers must be connected to the electric service shown on the dryer’s data label. The connecting wires must be properly sized to handle the rated current.

ELECTRICAL SERVICE SPECIFICATIONS

IMPORTANT: 208 VAC AND 230/240 VAC ARE NOT THE SAME. When ordering, specify exact voltage.

NOTES: | A. | When fuses are used they must be dual element, time delay, current limiting, class RK1 or RK5 |

|

| ONLY. Calculate/determine correct fuse value, by applying either local and/or National Electrical |

| B. | Codes to listed appliance amp draw data. |

| Circuit breakers are | |

| C. | breaker size according to appliance amp draw rating and type of breaker used. |

| Circuit breakers for |

SERVICE |

| WIRE |

| OVEN | APPROX. | CIRCUIT | |

PHASE |

| AMP DRAW | |||||

VOLTAGE | SERVICE |

| kW | BREAKER | |||

|

| 60 Hz | 50 Hz | ||||

|

|

|

|

|

| ||

|

|

| T20 |

|

|

| |

200 | 1ø | 2 |

| 5.6 | 32.7 | 32.7 | 45 |

208 | 1ø | 2 |

| 4.1 | 24.2 | — | 35 |

208 | 1ø | 2 |

| 6.1 | 34.0 | — | 45 |

220 | 1ø | 2 |

| 6.8 | 35.6 | — | 45 |

230 | 1ø | 2 |

| 5.0 | — | 26.4 | 35 |

230 | 1ø | 2 |

| 7.4 | — | 36.8 | 50 |

240 | 1ø | 2 |

| 5.4 | 27.1 | — | 35 |

240 | 1ø | 2 |

| 8.1 | 38.4 | 38.4 | 50 |

208 | 3ø | 3 |

| 6.5 | 22.7 | — | 30 |

240 | 3ø | 3 |

| 7.5 | 22.6 | — | 30 |

380 | 3ø | 4 |

| 6.8 | — | 15.0 | 20 |

400 | 3ø | 4 |

| 7.5 | — | 15.5 | 20 |

416 | 3ø | 4 |

| 8.1 | — | 15.8 | 20 |

|

|

| T30 |

|

|

| |

200 | 1ø | 2 |

| 12.5 | 68.4 | 67.7 | 90 |

208 | 1ø | 2 |

| 7.9 | 43.8 | — | 60 |

208 | 1ø | 2 |

| 13.5 | 70.7 | — | 90 |

230 | 1ø | 2 |

| 8.3 | — | 41.3 | 60 |

230 | 1ø | 2 |

| 12.4 | — | 59.1 | 80 |

240 | 1ø | 2 |

| 9.0 | 42.7 | — | 60 |

240 | 1ø | 2 |

| 13.5 | 61.5 | — | 80 |

208 | 3ø | 3 |

| 13.5 | 43.3 | — | 60 |

220 | 3ø | 3 |

| 11.3 | 35.3 | — | 50 |

230 | 3ø | 3 |

| 12.4 | — | 36.5 | 50 |

240 | 3ø | 3 |

| 13.5 | 37.7 | — | 50 |

380 | 3ø | 4 |

| 11.3 | 22.8 | 22.6 | 40 |

400 | 3ø | 4 |

| 12.4 | — | 23.1 | 40 |

416 | 3ø | 4 |

| 13.5 | — | 23.7 | 40 |

|

|

| T50 |

|

|

| |

200 | 1ø | 2 |

| 14.8 | 82.1 | — | 110 |

208 | 1ø | 2 |

| 16.0 | 85.1 | — | 110 |

220 | 1ø | 2 |

| 13.4 | 68.8 | 69.4 | 90 |

230 | 1ø | 2 |

| 14.7 | — | 72.3 | 100 |

240 | 1ø | 2 |

| 16.0 | 74.2 | 75.1 | 100 |

200 | 3ø | 3 |

| 14.8 | — | 51.0 | 70 |

208 | 3ø | 3 |

| 16.0 | 52.6 | — | 70 |

220 | 3ø | 3 |

| 13.4 | 43.0 | 43.6 | 60 |

230 | 3ø | 3 |

| 14.7 | — | 45.3 | 60 |

240 | 3ø | 3 |

| 16.0 | 46.0 | — | 60 |

380 | 3ø | 4 |

| 13.4 | 28.0 | 28.6 | 40 |

400 | 3ø | 4 |

| 14.8 | — | 29.8 | 40 |

416 | 3ø | 4 |

| 16.0 | — | 30.7 | 40 |

|

| T50 Dual Voltage 480 / 120 |

|

| |||

120 | 1ø | 2 |

| 0.0 | 13.2 | — | 15 |

480 | 3ø | 3 |

| 16.0 | 19.2 | — | 25 |

|

| T50 Dual Voltage 480 / 240 |

|

| |||

240 | 1ø | 2 |

| 0.0 | 6.5 | — | 15 |

480 | 3ø | 3 |

| 16.0 | 19.2 | — | 25 |

|

| T50 Dual Voltage 600 / 120 |

|

| |||

120 | 1ø | 2 |

| 0.0 | 13.2 | — | 15 |

600 | 3ø | 3 |

| 16.0 | 15.4 | — | 20 |

|

| T50 Dual Voltage 600 / 240 |

|

| |||

240 | 1ø | 2 |

| 0.0 | 6.5 | — | 15 |

600 | 3ø | 3 |

| 16.0 | 15.4 | — | 20 |

|

|

| T75 |

|

|

| |

200 | 1ø | 2 |

| 20.3 | 109.8 | — | 150 |

208 | 1ø | 2 |

| 22.0 | 113.9 | — | 150 |

220 | 1ø | 2 |

| 18.5 | 91.7 | 92.3 | 125 |

230 | 1ø | 2 |

| 20.3 | — | 96.3 | 125 |

240 | 1ø | 2 |

| 22.0 | 99.2 | — | 125 |

208 | 3ø | 3 |

| 22.0 | 69.2 | — | 90 |

220 | 3ø | 3 |

| 18.5 | 56.2 | 56.8 | 80 |

230 | 3ø | 3 |

| 20.3 | — | 59.1 | 80 |

240 | 3ø | 3 |

| 22.0 | 60.4 | — | 80 |

380 | 3ø | 4 |

| 18.5 | 35.6 | — | 45 |

380 | 3ø | 4 |

| 18.5 | — | 36.2 | 50 |

400 | 3ø | 4 |

| 20.3 | — | 37.8 | 50 |

416 | 3ø | 4 |

| 22.0 | — | 39.1 | 50 |

7/15/08

Grounding

A ground (earth) connection must be provided and installed in accordance with local, state, and national regulations or codes of the country of origin. In the absence of these codes, grounding must conform to applicable requirements of the National Electrical Code ANSI/NFPA NO.

For added personal safety, when possible, it is suggested that a separate ground wire (size per local codes) be connected from the ground connection of the dryer to a grounded cold water pipe. Do not ground to a gas pipe or hot water pipe. The grounded cold water pipe must have

Important

!For personal safety and proper operation, the dryer must be grounded.

Provisions are made for ground connection in each dryer at the electrical service connection area.

Warning

!Electrical Grounding Instructions – This dryer is equipped with a

protection against shock hazard and should be plugged directly into a properly grounded

Electrical Connections

A wiring diagram is located behind the control panel for connection data.

If local codes permit, power to the dryer can be made by the use of a flexible UL listed power cord/pigtail (wire size must conform to rating of dryer), or the dryer can be hard wired directly to the service breaker panel. In both cases, a strain relief must be installed where the wiring enters the dryer.

For CE Models Only

The means for disconnection from the supply must be incorporated into wiring having a minimum contact separation of 3.0mm in all poles.

Single-Phase (1ø)

Wiring Connections/Hookup

The electrical input connections are made into the rear service box located at the upper right area of the dryer. The ground connection is made to the copper lug, also provided in this box. To gain access, the service box cover must be removed.

113429 - 9 | Telephone 01422 822282 | 19 |