Gas Pressure Testing _________________

For proper operation, the gas pressure must be correct, consistent and maintained at the gas pressure rates shown on page 22. Provisions are made at the gas valve for taking gas pressure readings.

There are 2 types of devices used to measure gas pressure. They are the spring/mechanical type gauge and the manometer. The use of the spring/mechanical type gauge is not recommended because they are very easily damaged and are not always accurate. The preferred type of gauge is the manometer because it is a simple device to use and is highly accurate. A manometer is simply a glass or transparent plastic tube with a scale graduated in inches or mb. When it is filled with water and pressure is applied, the water in the tube rises, showing the exact gas pressure.

Gas Pressure Test Procedure

Turn gas cock in gas supply line to “OFF” position.

50 Hz dryers: Back out miniature screw inside pressure tap and attach manometer (refer to the illustration on page 24).

60 Hz dryers: Install pressure tap and attach manometer (refer to illustration on page 24).

Turn gas cock to “ON” position.

Start the dryer in Heat Mode and wait for ignition. Gas manifold pressure should be as shown on page 22.

If the gas pressure needs to be adjusted, refer to “Gas Pressure Adjustment” on page 25.

Once test is complete, turn gas cock to “OFF” position. Remove manometer. Tighten screw inside the pressure tap or install plug.

Turn gas cock to “ON” position and check for leaks with soap solution with main burner “ON.”

Steam Information ____________________

It is your responsibility to have all plumbing connections made by a qualified professional to ensure that the steam plumbing installation is adequate and conforms with local, state, and country regulations or codes.

Care must be exercised when leveling steam dryers into final position. After leveling the dryer, check the downward pitch of the heat exchanger from front to rear with a level. Likewise, check the downward pitch of the return condensate manifold toward its outlet part. Absence of these downward pitches will result in probable water hammer and premature heat exchanger fracture and leakage.

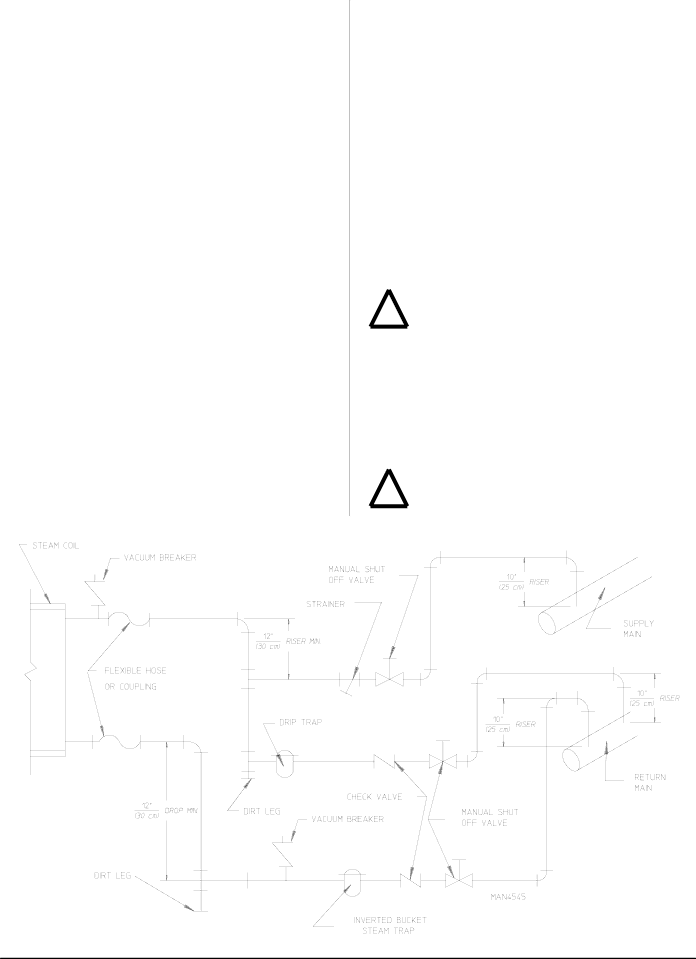

The presence of condensate in the steam will cause water hammer and subsequent heat exchanger failure. The steam supply connection must be taken from the top of a well- dripped steam main. If the supply

Important

!Failure to comply with the requirements stipulated in this manual can result in component failure,

which will void the warranty.

Steam Coil pH Level

The normal pH level for copper type steam coils must be maintained between a value of 8.5 to 9.5. For steel type steam coils the pH level must be maintained between a value of 9.5 to 10.5. These limits are set to limit the acid attack of the steam coils.

Important

!Coil failure due to improper pH level will void the warranty.

26 | JLA Limited | 113429 - 9 |